Rotary positioning device based on accumulating chain

A positioning device and the technology of product chain, which is applied in the field of product chain, can solve the problems of inability to rotate and position materials, increase equipment investment costs, multiple workshop areas and spaces, etc., to ensure accurate spraying, improve equipment operation efficiency, and facilitate later stages The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

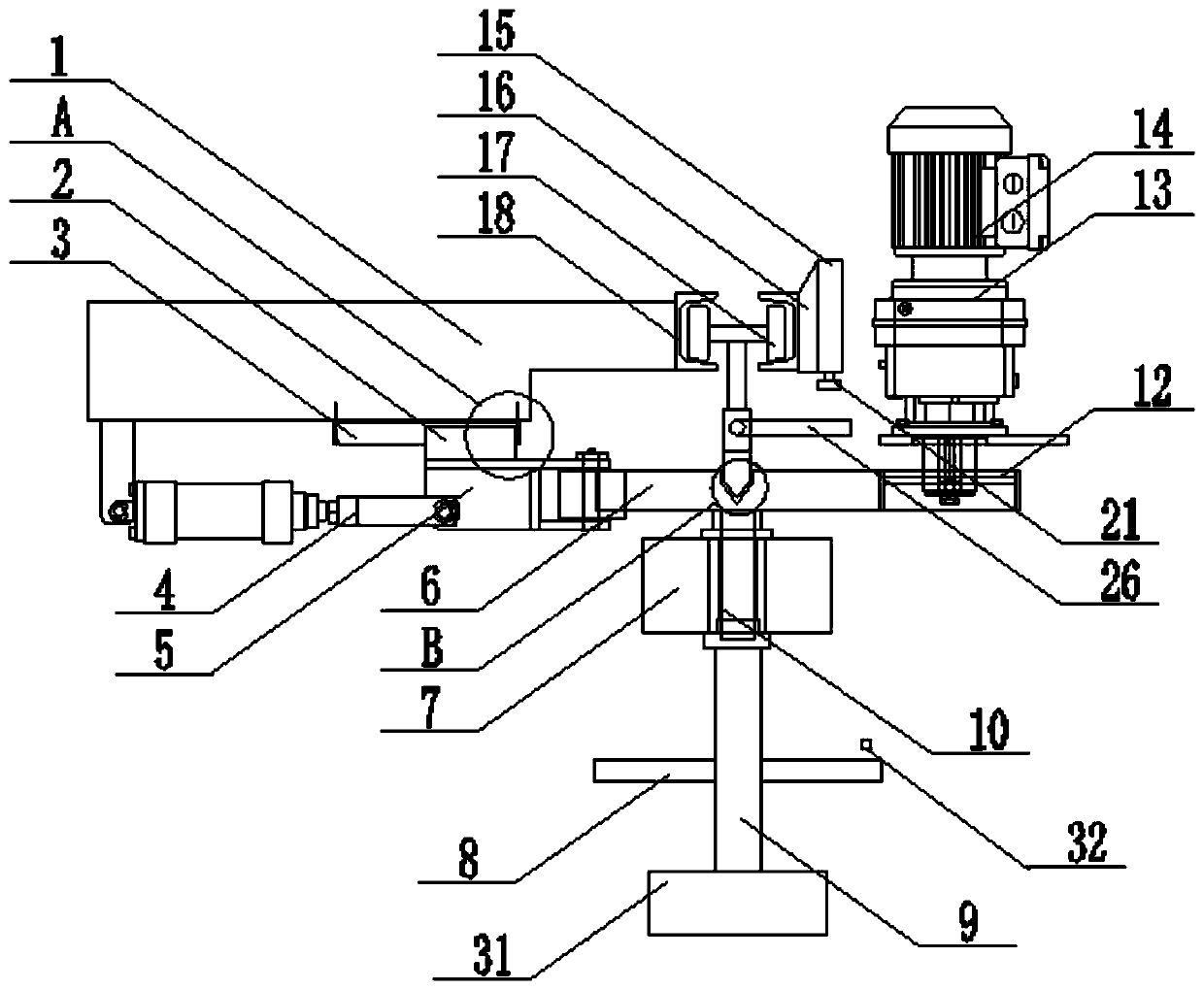

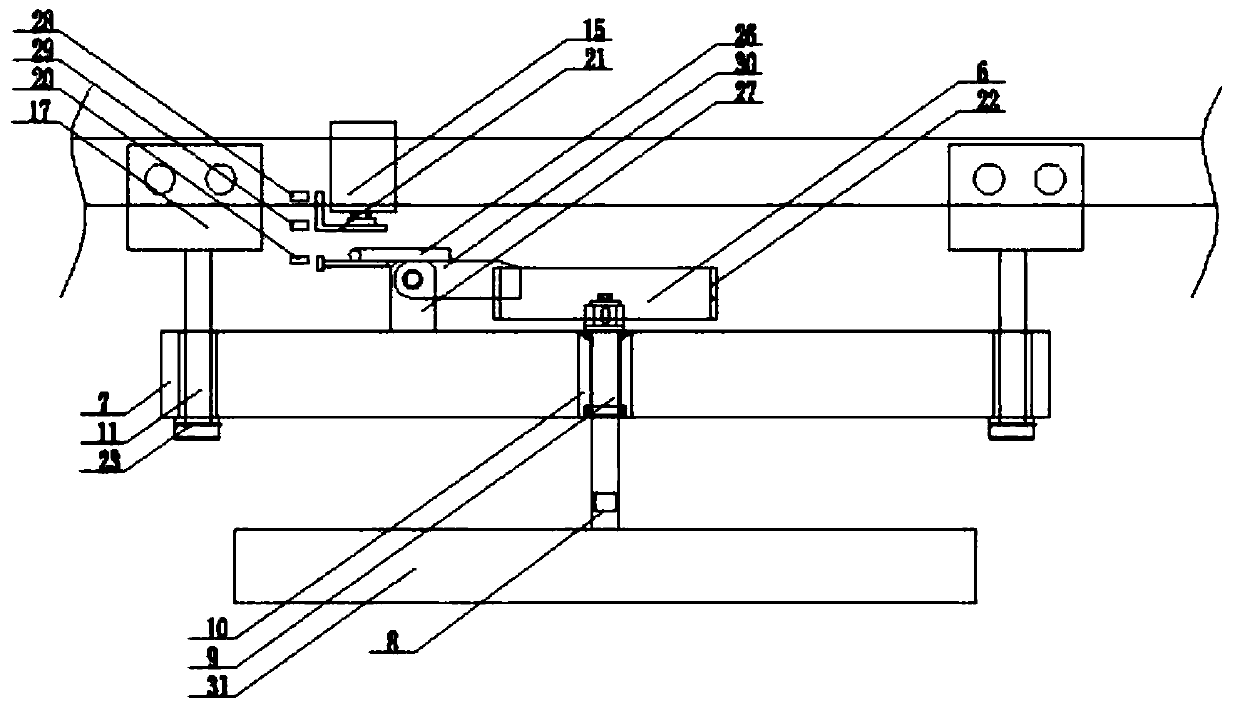

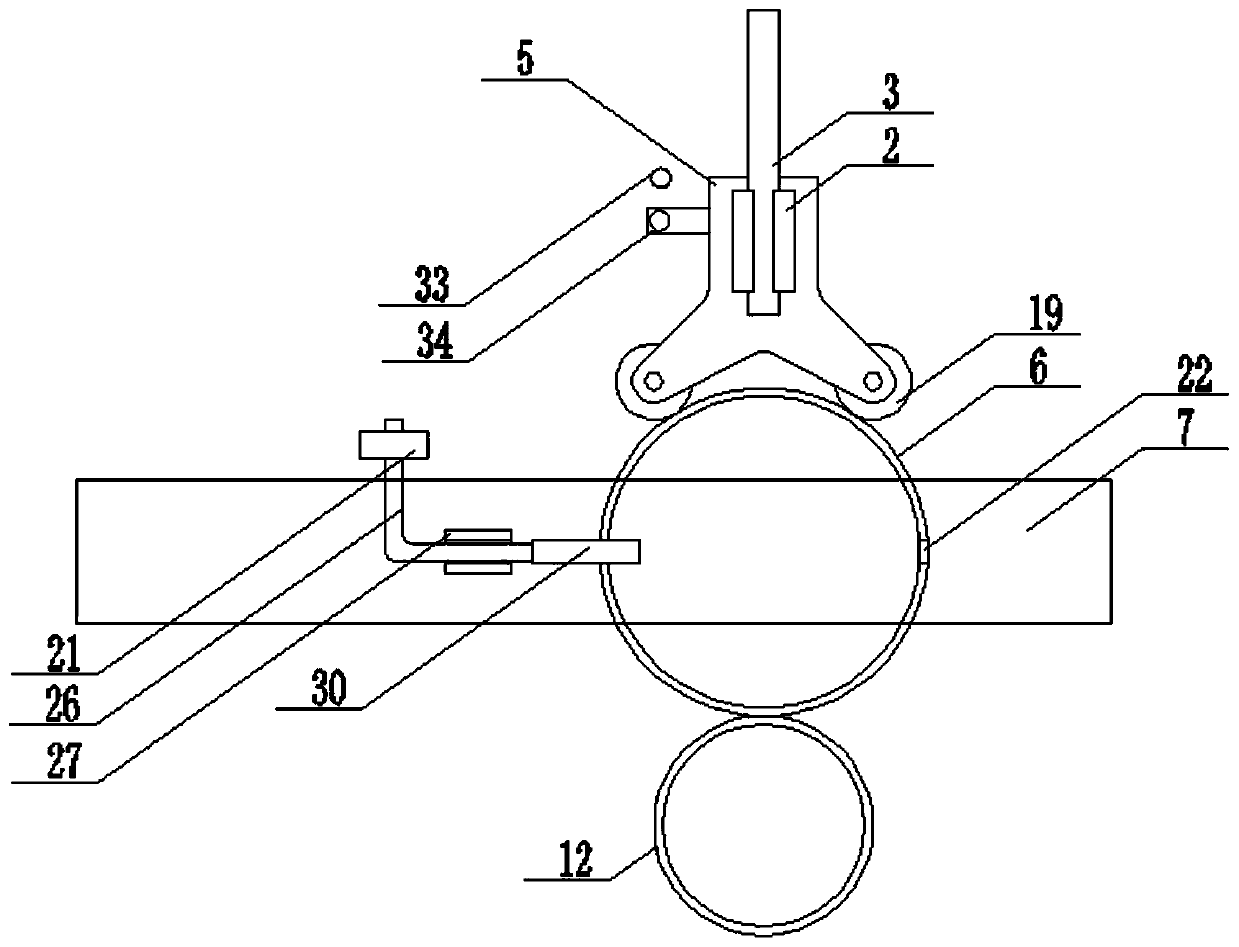

[0030] refer to figure 1 , 2 , 3, 5, a kind of rotary positioning device based on accumulation chain, comprise two rails 18, two moving mechanisms 17 are installed jointly between two rails 18, facilitate moving mechanism 17 to move stably, the two moving mechanisms 17 The lower ends are fixed with bearing rods 11. When the moving mechanism 17 moves, it drives the bearing rods 11 to move. The lower ends of the two bearing rods 11 run through the bearing blocks 7. The movement of the bearing rods 11 drives the bearing blocks 7 to move. Bearing 10 is installed, and one side of the upper end of bearing block 7 is fixed with support rod 27, and the upper end of support rod 27 is connected with lifting pin fork 30 in rotation, and the upper end of lifting pin fork 30 is fixed with fixed plate 26, and fixed plate 26 moves to drive The pin lifting swing bar 30 moves, and under the action of the moving mechanism 17, the position of the friction wheel 6 is conveniently adjusted;

[0...

Embodiment 2

[0036] refer to figure 1 , 2, 3, 5, a kind of rotary positioning device based on accumulation chain, comprise two rails 18, two moving mechanisms 17 are installed jointly between two rails 18, facilitate moving mechanism 17 to move stably, the two moving mechanisms 17 The lower ends are fixed with bearing rods 11. When the moving mechanism 17 moves, it drives the bearing rods 11 to move. The lower ends of the two bearing rods 11 run through the bearing blocks 7. The movement of the bearing rods 11 drives the bearing blocks 7 to move. Bearing 10 is installed, and one side of the upper end of bearing block 7 is fixed with support rod 27, and the upper end of support rod 27 is connected with lifting pin fork 30 in rotation, and the upper end of lifting pin fork 30 is fixed with fixed plate 26, and fixed plate 26 moves to drive The pin lifting swing bar 30 moves, and under the action of the moving mechanism 17, the position of the friction wheel 6 is conveniently adjusted;

[00...

Embodiment 3

[0043] refer to figure 1 , 2 , 3, 4, 5, a kind of rotary positioning device based on accumulation chains, including two rails 18, two moving mechanisms 17 are installed between the two rails 18, to facilitate the stable movement of the moving mechanism 17, the two moving mechanisms The lower ends of 17 are fixed with bearing rods 11, and when the moving mechanism 17 moves, it drives the bearing rods 11 to move. The lower ends of the two bearing rods 11 run through the bearing blocks 7, and the moving of the bearing rods 11 drives the bearing blocks 7 to move. A bearing 10 is installed in the middle part of the upper end, and a support rod 27 is fixed on one side of the upper end of the bearing block 7, and the upper end of the support rod 27 is rotatably connected with a lifting pin swing rod 30, and the upper end of the lifting pin swing rod 30 is fixed with a fixed plate 26, and the fixed plate 26 The movement drives the pin lifting swing bar 30 to move, and under the actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com