Automatic control air compressor loading system

A loading system and air compressor technology, applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of short service life of the device, inability to perform temperature and pressure dynamic curves and display alarms, damage, etc. Achieve the effect of improving reliability and service life, stable and reliable long-term work, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

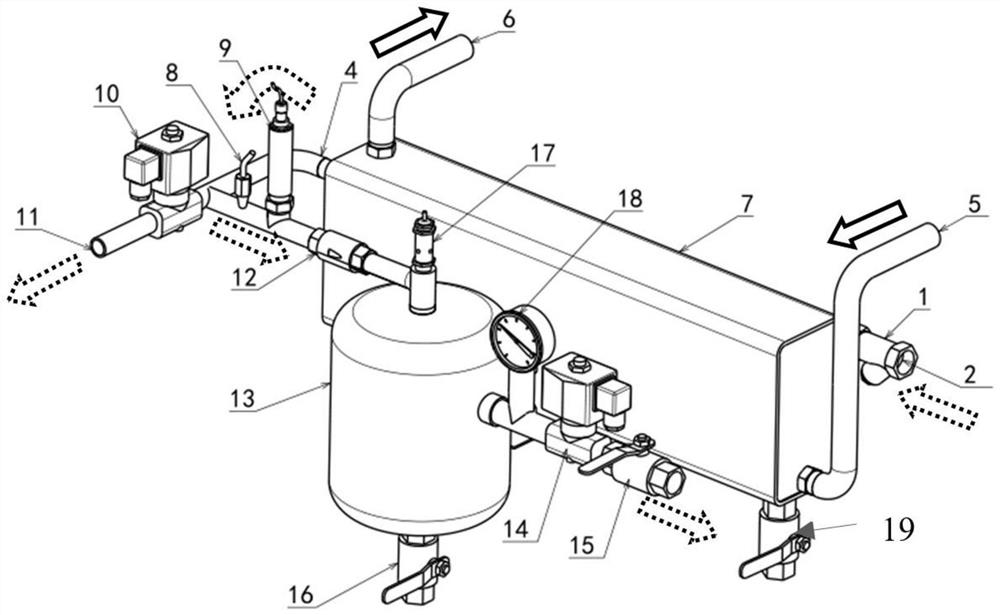

[0056] As an optimized embodiment of the present invention: the water inlet 5 of the cooling water tank 7 and the air inlet 1 of the cooling pipe 3 are on the same side wall of the cooling water tank 7 . Preferably, the water outlet 6 of the cooling water tank 7 is located at the top of the cooling water tank 7 . Preferably, a drain valve 19 is provided at the bottom of the cooling water tank 7 .

[0057] For the buffer tank 13, the present invention adopts various schemes to optimize it: a check valve 12 is provided between the inlet of the buffer tank 13 and the outlet pipeline. A safety valve 17 is provided at the air inlet of the buffer tank 13 . The inlet of the back pressure solenoid valve 14 is connected to the buffer tank 13, the outlet is connected to the inlet of the throttle valve 15, and the outlet of the throttle valve 15 is connected to the outside world. A pressure gauge 18 is provided between the back pressure solenoid valve 14 and the buffer tank 13 . A dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com