Sauce aromatic vinegar and preparation technology thereof

A preparation process and sauce aroma technology, which is applied in the preparation of vinegar, medical preparations containing active ingredients, anti-virus agents, etc., can solve the problem that vinegar cannot satisfy consumers' tastes, and achieve the effect of delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The sauce-flavored vinegar prepared by the preparation process provided in this example is glossy, rich in sauce, vinegar, and delicious, and caters to the preferences of most consumers.

[0031] It should be noted that, in this embodiment, cooked corn refers to cooked corn flour. It should be noted that, in other embodiments of the present invention, corn grains can also be directly cooked.

[0032] Further, the volume ratio of the mixture to the wheat bran is 3-4:1, and the mixed mixture and the wheat bran are stirred once a day. Sauce vinegar is very particular about the quantity and quality of wheat bran, as well as the manual mixing process. After many experiments, the inventor found that the volume ratio of the mixture to the wheat bran is 3-4:1, and it is better to stir in time, once a day, and mix evenly to make it fully fermented.

[0033] In other embodiments of the present invention, before adding the vinegar koji to the boiled corn, the boiled corn is seal...

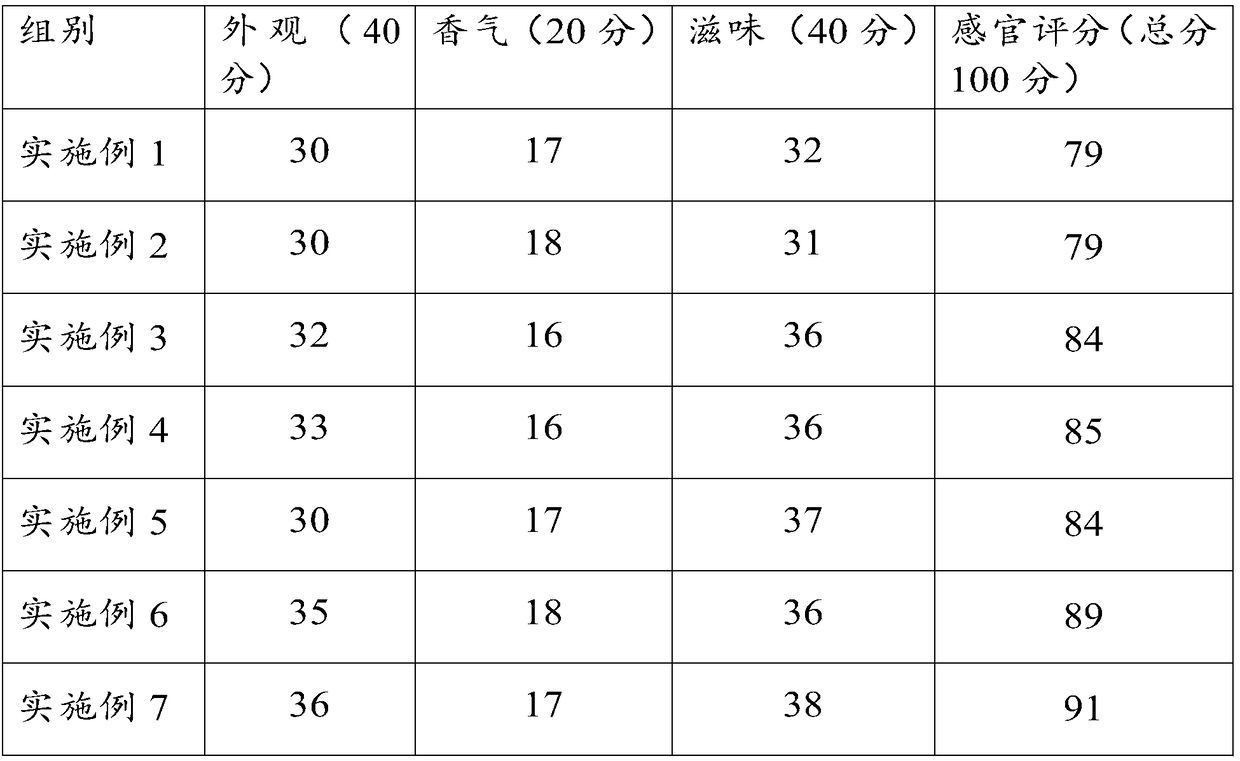

Embodiment 1

[0075] This embodiment provides a kind of soy sauce vinegar, which is mainly prepared through the following steps:

[0076] Add vinegar koji to cooked corn and ferment for 15 days to obtain the mixture; mix the mixture with wheat bran, the volume ratio of the mixture and wheat bran is 3:1, make vinegar germ at 40°C, and store the vinegar germ in a sealed manner for 12 days Stir the mixed mixture and wheat bran once a day for one month; then mix and soak with fried rice and water for 2 days, filter, and sterilize and package the filtrate under high pressure and high temperature.

[0077] Vinegar koji is commercially available vinegar koji.

Embodiment 2

[0079] This embodiment provides a kind of soy sauce vinegar, which is mainly prepared through the following steps:

[0080] Add vinegar koji to cooked corn and ferment for 18 days to obtain the mixture; mix the mixture with wheat bran, the volume ratio of the mixture and wheat bran is 4:1, make vinegar germ at 35°C, and store the vinegar germ in a sealed manner for 11 days months; then mixed with fried rice and water and soaked for 2 days, filtered, and the filtrate was sterilized and packaged under high pressure and high temperature.

[0081] Vinegar koji is commercially available vinegar koji.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com