A method for on-line transformation of rail foundation under furnace

A foundation and rail technology, which is applied in the field of on-line transformation of steel rail foundation under the furnace, can solve problems such as unrealizable, poor strength, and non-long-term treatment, and achieve high support strength, short construction time, and good high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0025] The present invention provides a method for on-line transformation of steel rail foundations under a furnace, comprising the following steps:

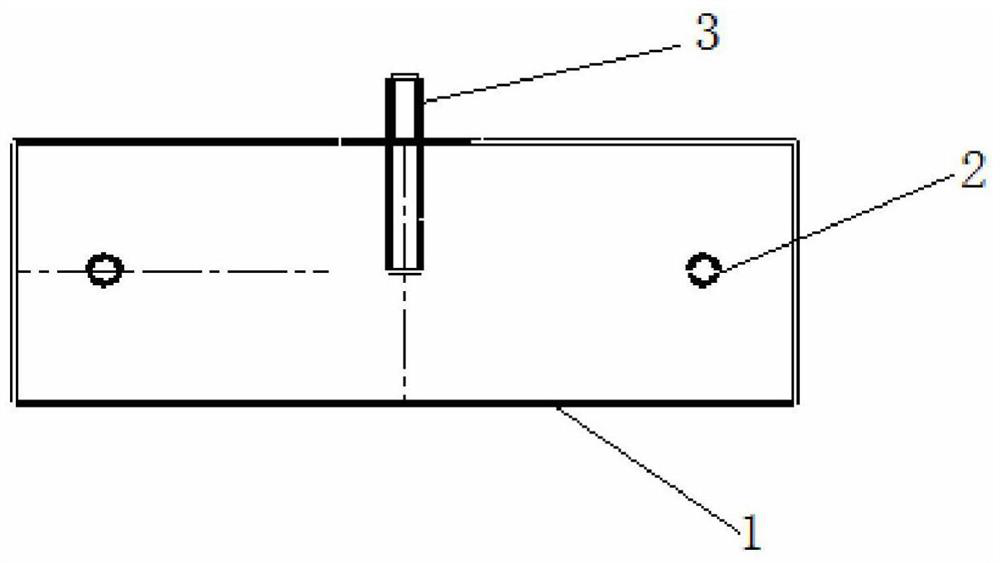

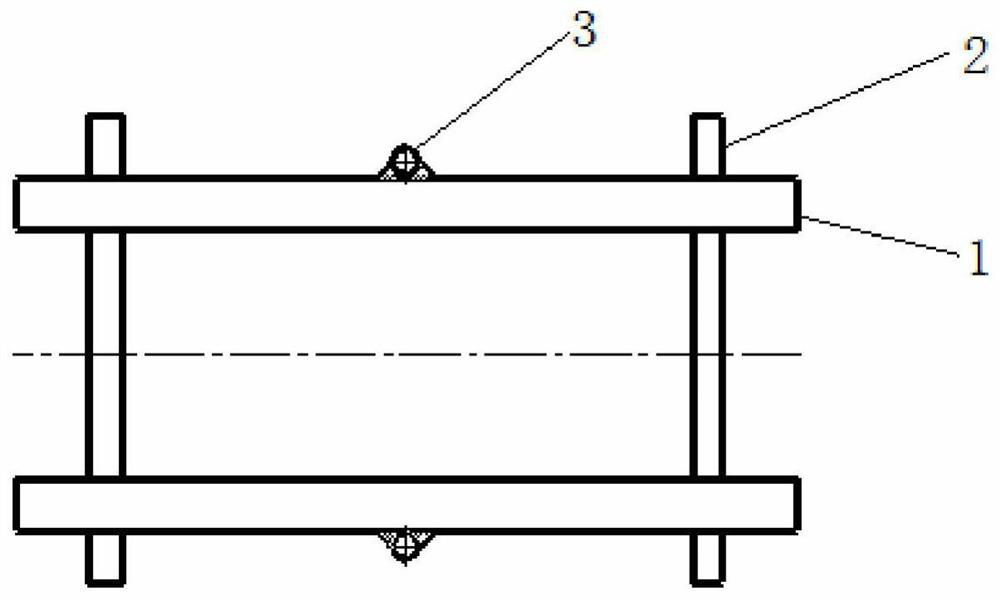

[0026] Prefabricated steel frames such as figure 1 , 2 shown;

[0027] Make pits with a width of 380-420 mm and a depth of 250-300 mm downwards on the rail foundation under the furnace;

[0028] The pit is leveled with reinforced concrete, and the depth is -0.39m above sea level;

[0029] Lay the prepared multiple steel frames in the pit, and weld two adjacent frames firmly;

[0030] After the high-strength grouting material is poured into the pit of the steel frame, the 20mm steel plate is laid on the top according to the normal rail construction. The steel plate is opened with a Φ25-26mm round hole at the corresponding part of the frame welding bolt, and the nut is firmly welded to the steel pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com