Railway rescue station with smoke prevention and exhaust and personnel emergency evacuation functions

A technology for emergency evacuation and rescue stations, applied in the field of railway rescue stations, can solve the problems of increasing tunnel cross-sectional area, large shaft size, and construction waste, so as to reduce the increase in the number of shafts, reduce the increase in shaft size, and reduce construction costs. The effect of technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

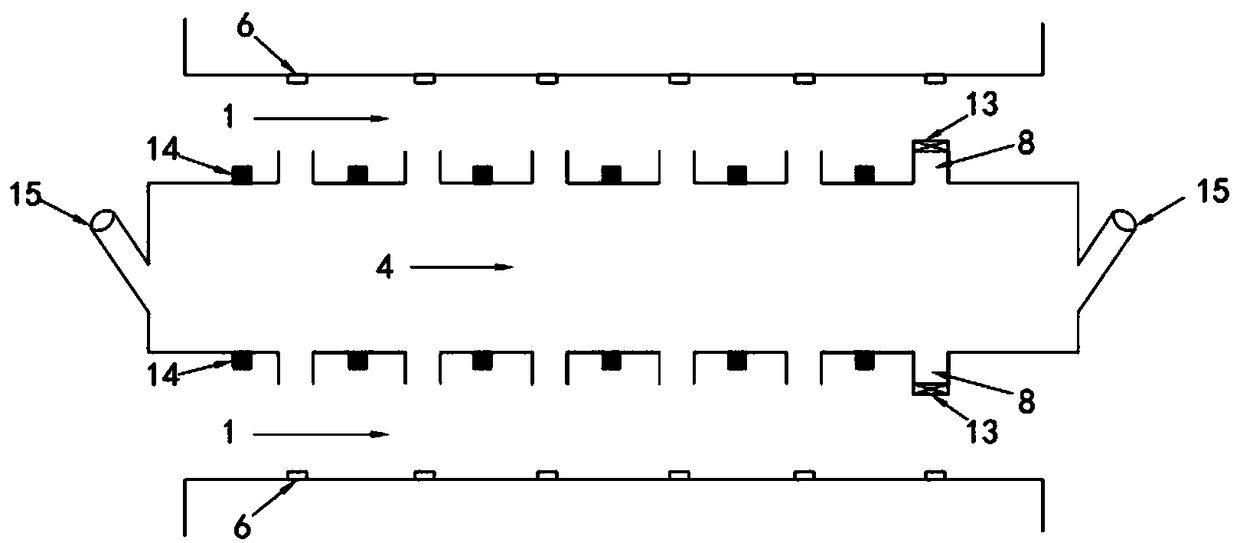

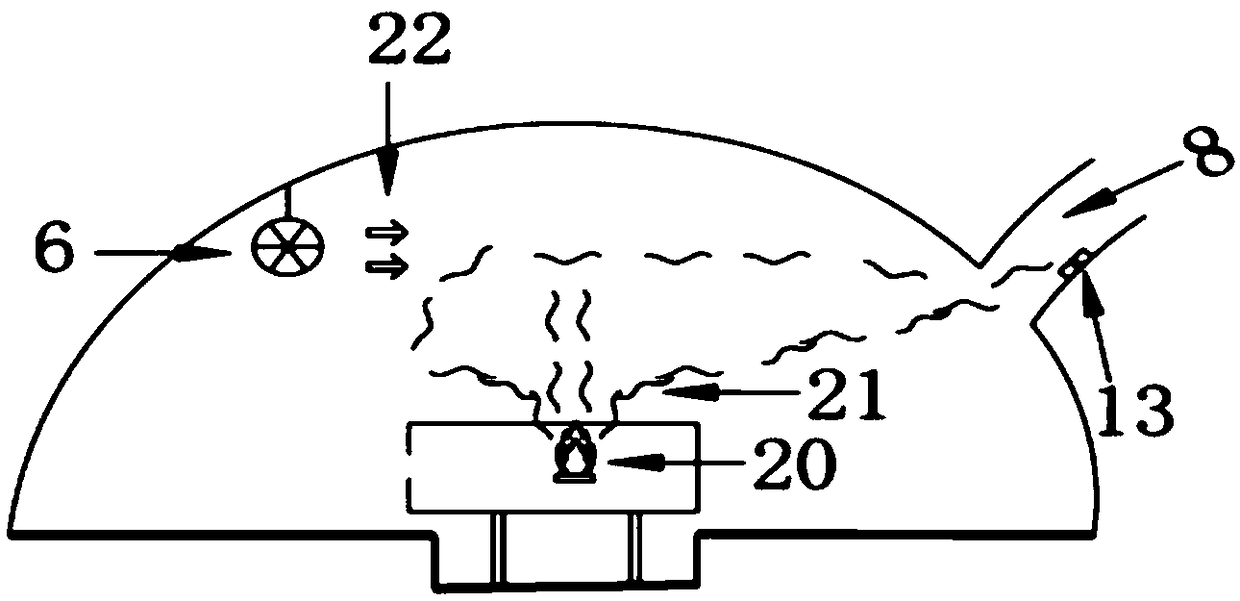

[0059] When the tail of the train was on fire, in this case, after the fire train drove into the rescue station, all the doors and windows of the train at the downstream end of the rescue station were opened, and the passengers entered the tunnel evacuation layer 2 by the evacuation stairs 5 and then entered the rest of the tunnel by the evacuation passage 3. The fire tunnel awaits rescue. Open the remote control smoke exhaust damper 13 in the smoke exhaust port 8 downstream of the rescue station, and simultaneously move the jet fan unit 12 to determine the smoke exhaust direction from the upstream of the burning part of the fire train, and then gradually move to the fire source position. The gas concentration and flow velocity are adjusted to different positions and the wind force cooperates with the smoke exhaust port 8 for longitudinal smoke exhaust and can prevent the downstream tunnel smoke from flowing backward. At the same time, the fire extinguishing chamber 11 is move...

Embodiment example 2

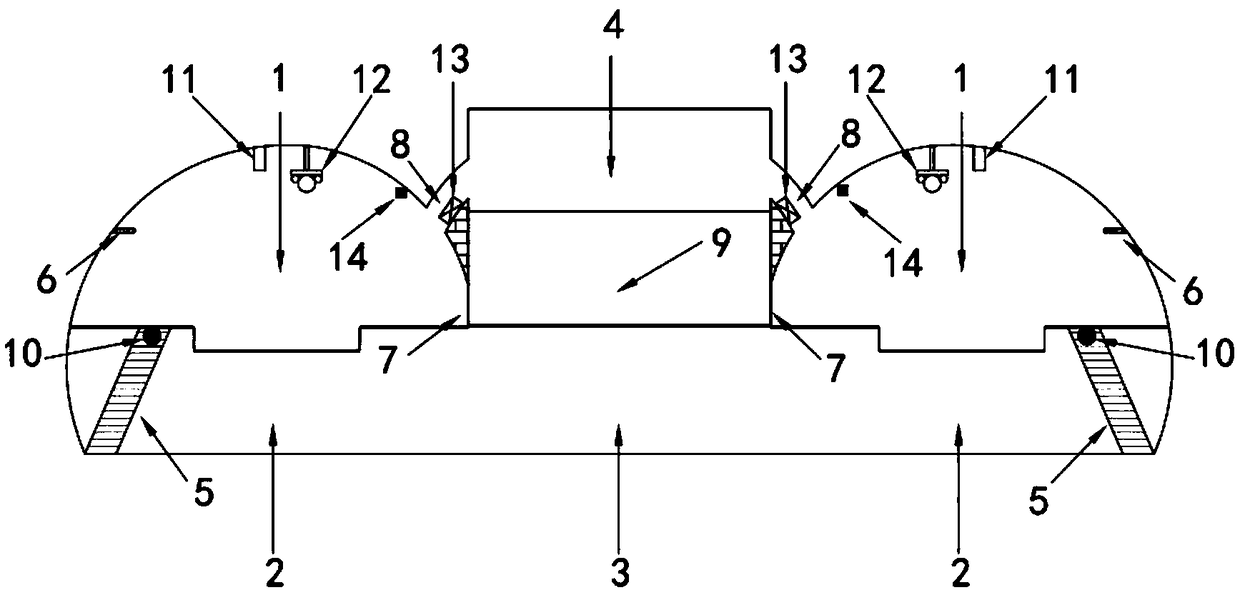

[0061] When the middle of the train is on fire, when the train stops at the rescue station, the fire source is in the middle of the rescue station. If the fire cannot be exhausted and extinguished in time, the smoke will quickly spread to the entire rescue station. In this case, the rescue measure is that all the doors and windows of the train are all opened, and the passengers enter the tunnel evacuation layer 2 by the evacuation stairs 5 and then enter the unfired tunnel by the evacuation passage 3 and wait for rescue. Fire smoke detection modules 14 and directional jet fans 6 are installed longitudinally along both sides of the tunnel in the track area of the railway rescue station, and a mobile fire extinguishing chamber 11 and a mobile jet fan unit 12 are installed directly above the top of the tunnel. At this time, the fire smoke detection module 14 of the rescue station monitors the location of the fire source and the smoke concentration in the tunnel in real time. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com