Wind power blade with comb-shaped sawtooth structures and mounting method thereof

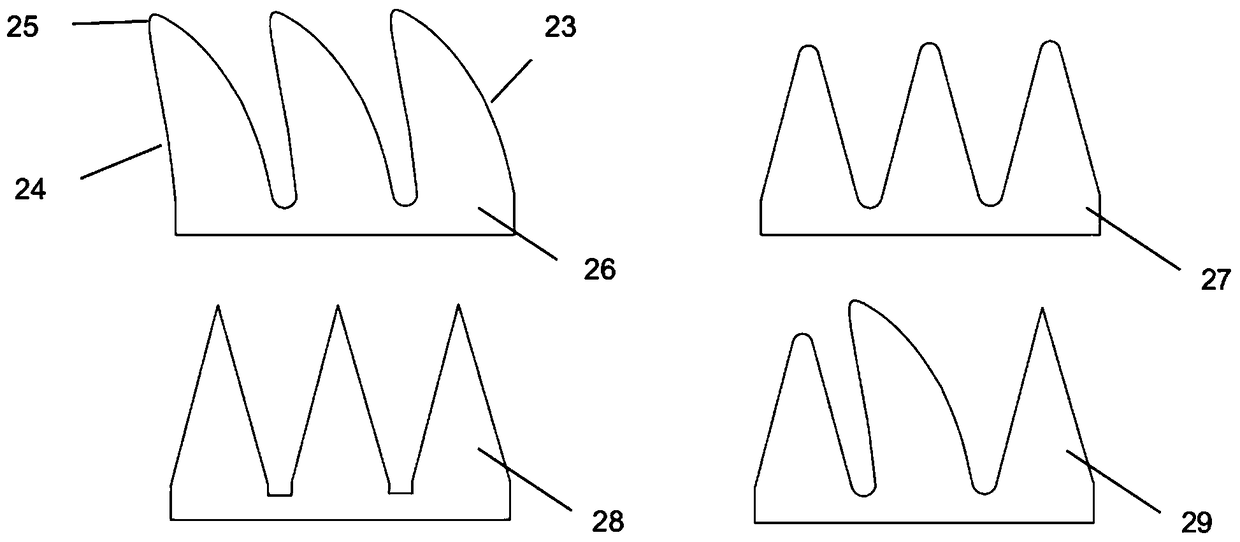

A technology of wind power blades and sawtooth, which is applied to wind power blades with comb-like sawtooth structure and its installation field, which can solve the problems of reducing the reliability of glue, large dynamic resistance, noise, etc., achieve accurate and reliable installation and positioning process, and reduce aerodynamic Good effect on noise and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention discloses a wind power blade equipped with a comb-like sawtooth structure and an installation method thereof. In order to make the invention more obvious and understandable, the invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

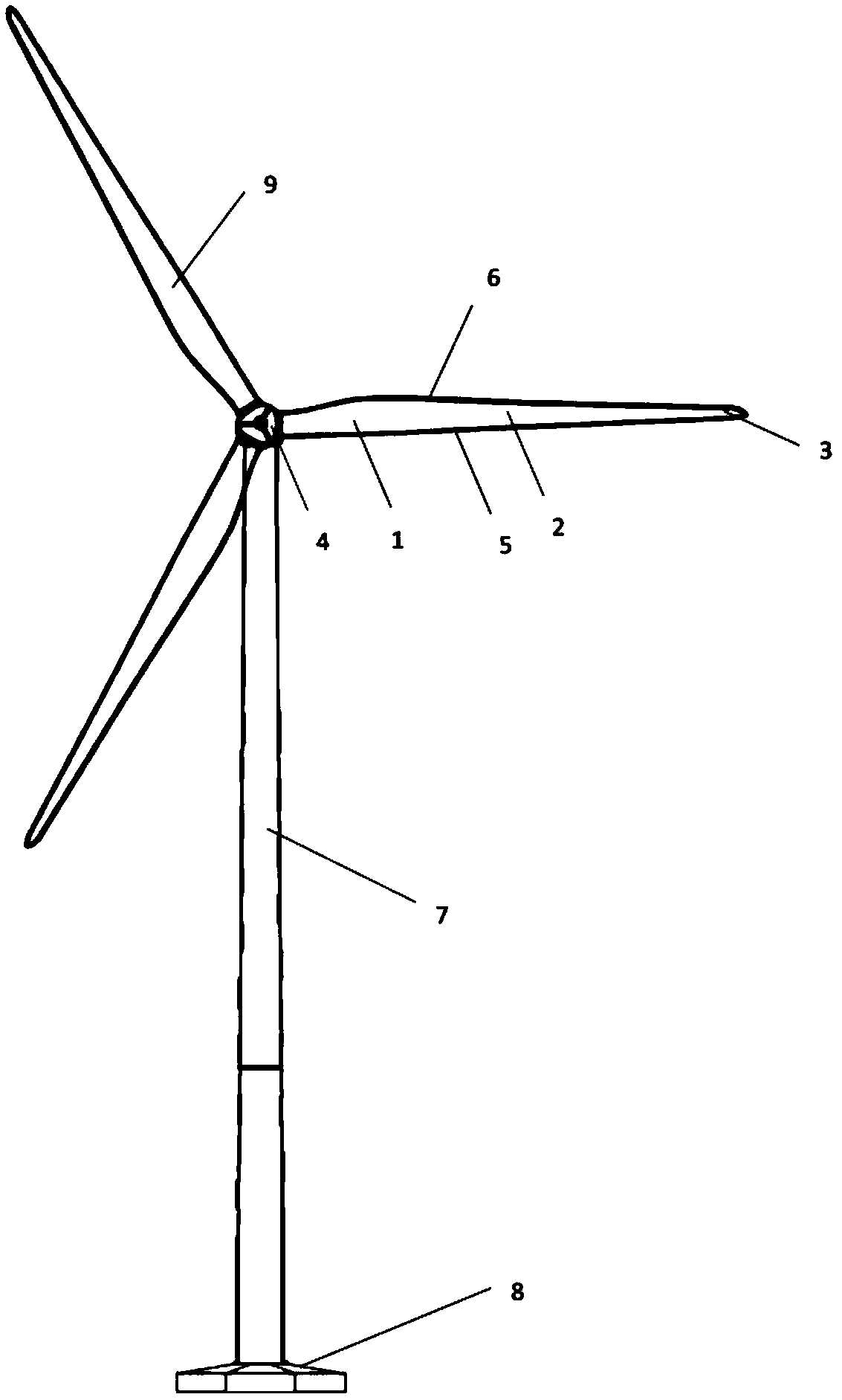

[0044] Such as figure 1 As shown, the wind turbine blade of the present invention includes a blade 9, a nacelle hub 4, a tower 7 and a foundation 8, and the tower 7 and the ground are fixed through the foundation 8 (the offshore unit may use other foundation forms). The blades 9 are connected to the hub 4 of the nacelle through bearings. The wind turbine absorbs wind energy through the blades 9 and drives the rotating shaft of the generator to generate electricity. The output power of the wind turbine is mainly determined by the performance of the blades 9 in absorbing wind energy.

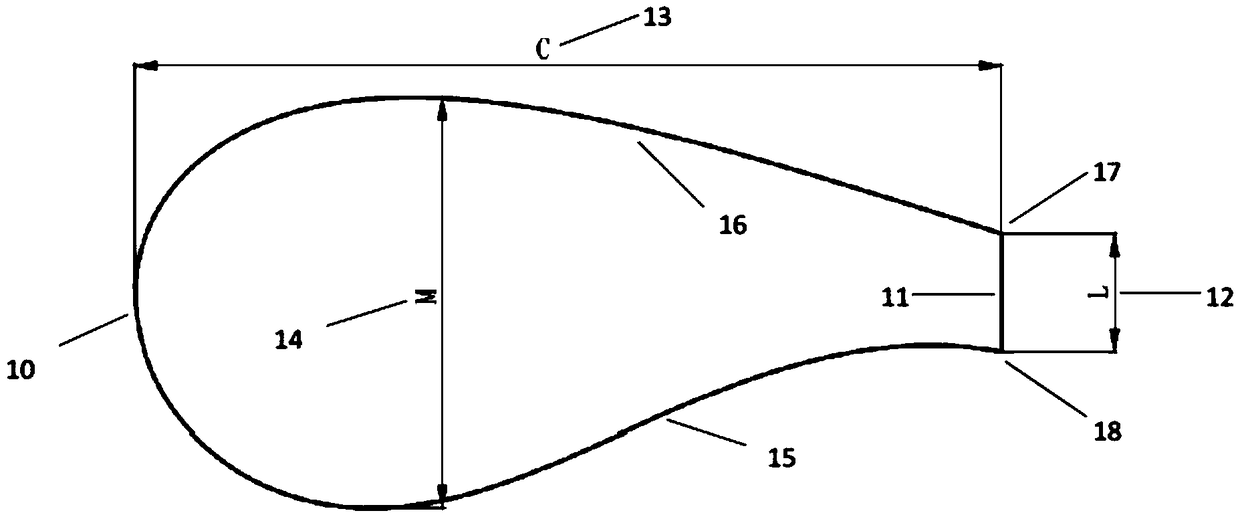

[0045] Wherein, the blade 9 comprises a blade root 1, a blade middle 2, a blade tip 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com