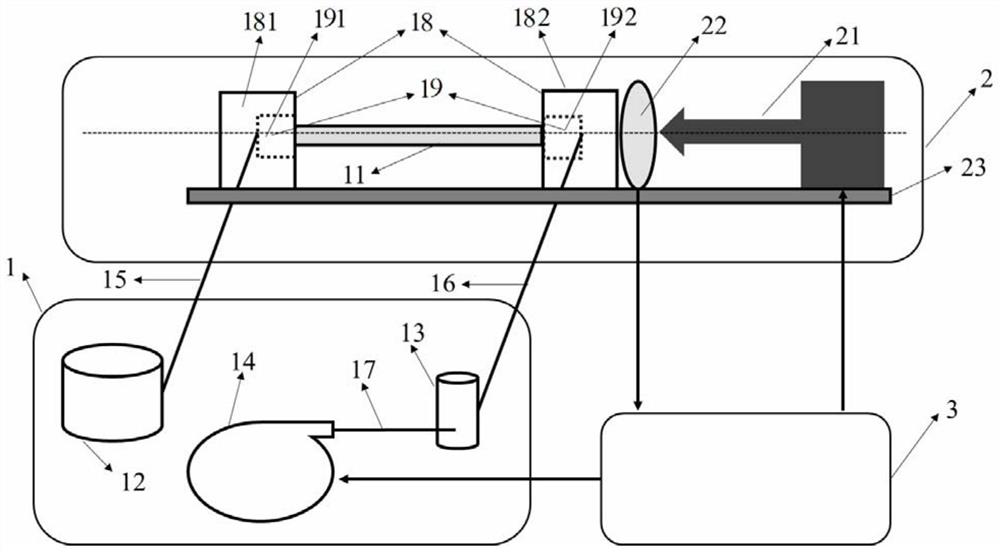

A solid-state refrigeration system with shape memory alloy tubing

A memory alloy, solid-state refrigeration technology, used in refrigerators, refrigeration and liquefaction, adsorption machines, etc., can solve problems such as lack of refrigeration effect and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

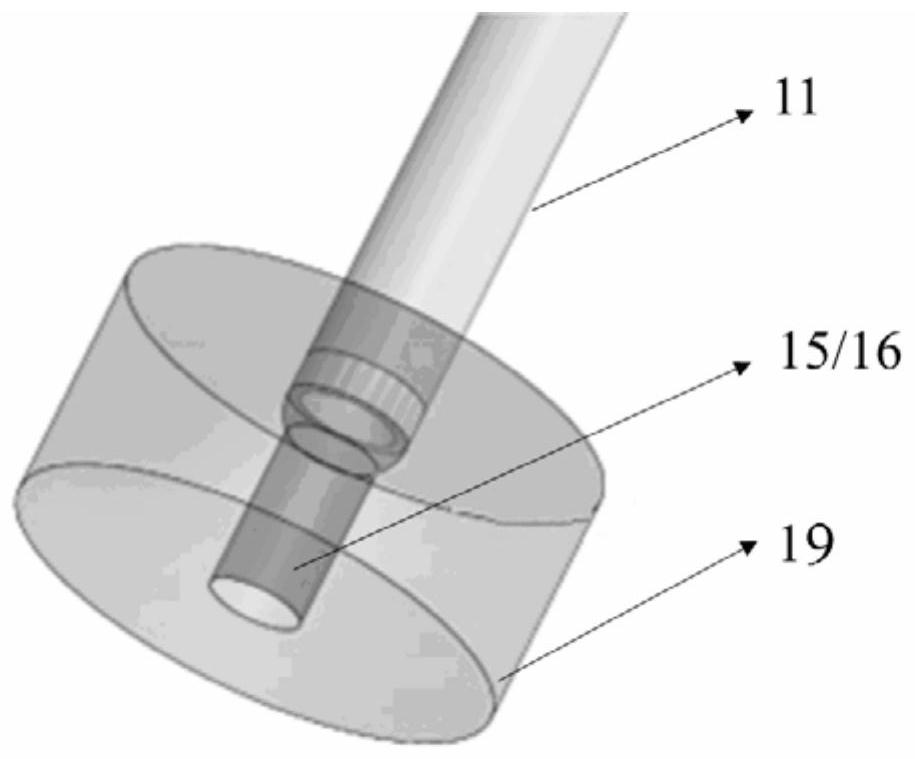

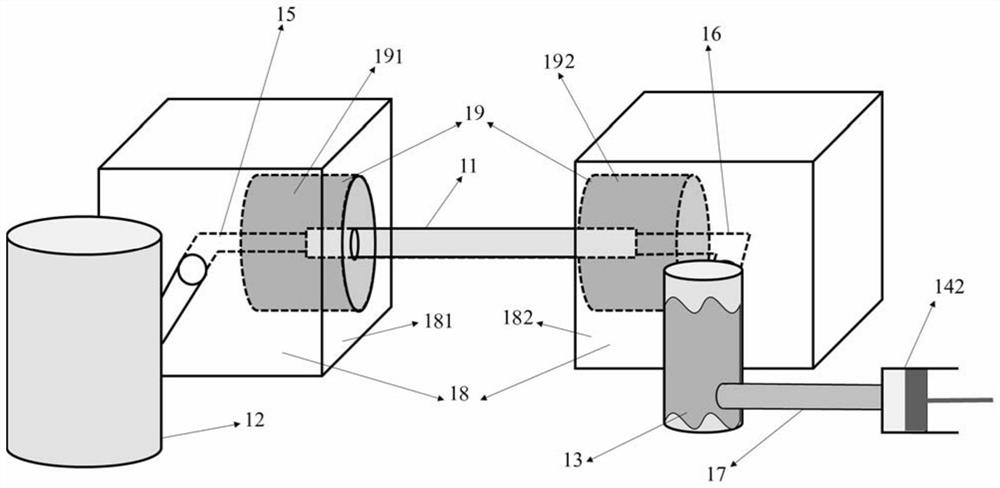

Method used

Image

Examples

Embodiment 1

[0136] Take a solid-state refrigeration system with a shape memory alloy tube, wherein the length of the shape memory alloy tube is 200mm. Use an electric press to apply pressure to the second transmission block at one end of the shape memory alloy tube, the first transmission block remains fixed, the frequency of the electric press to apply pressure is 0.25Hz, and the time for the electric press to apply pressure is 1.0s. The pressure applied by the electric press is 8000N. When the pressure applied by the electric press reaches 8000N, the time to maintain the pressure is 1.5s. The control mechanism receives the pressure value measured by the electric compressor on the second transmission block from the pressure measuring device, sends a pressure signal to the electric compressor to stop the pressurization of the electric compressor, and sends a pump signal to the refrigeration pump to make the refrigeration When the pump is running, the heat-absorbing agent in the hot-end c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com