Circumferential motion mechanism of tyre internal detonating device for tyre burst performance test

A technology of detonating device and circular motion, which is applied in the field of auto parts, can solve the problem of not being checked, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

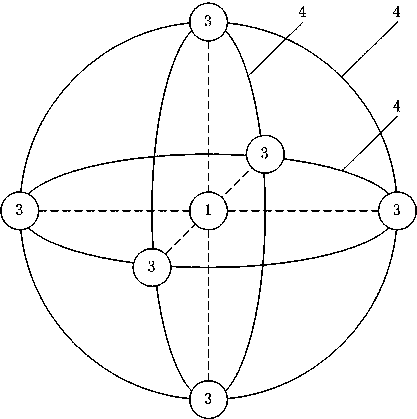

[0029] The detonating device in the tire of the tire blowout performance test based on circular motion of the present embodiment comprises a spherical housing 1, an detonating device arranged in the spherical housing 1, and three sets of permanent magnets 3 symmetrically arranged outside the spherical housing 1 for fixing the permanent magnets. The frame 4 of the magnet 3 is used to control the circular motion mechanism of the frame 4 movement; the spherical shell 1 is arranged inside the tire, and the permanent magnet 3, the frame 4 and the circular motion mechanism are arranged outside the tire;

[0030] Among them, the position and structural relationship between the spherical shell 1, the three groups of permanent magnets 3 and the frame 4 are as follows figure 1 shown;

[0031] The spherical shell 1 is a hollow spherical magnet with ventilation holes, the positive hemisphere is the N pole, and the negative hemisphere is the S pole;

[0032] Described detonating device co...

specific Embodiment 2

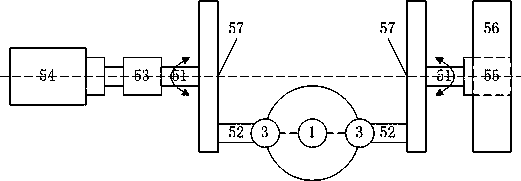

[0037] The tire blowout performance test device in this embodiment based on circular motion, on the basis of the specific embodiment 1, further defines that there is a rotating disc 57 between the rotating shaft 51 and the connecting rod 52, and the rotating shaft 51 is fixedly connected to the center of one side of the rotating disc 57 , the other side of the turntable 57 is installed with a screw 58 parallel to the turntable 57, the screw 58 is provided with a nut 59, and the nut 59 is fixedly connected with the connecting rod 52.

[0038] The position and structural schematic diagram between rotating shaft 51, connecting rod 52, rotating disk 57, screw rod 58 and nut 59 are as Figure 4 shown.

[0039] This structural limitation provides a specific mechanical structure for realizing the adjustable distance between the rotating shaft 51 and the connecting rod 52 .

specific Embodiment 3

[0040] The circular motion-based tire blowout performance testing device in this embodiment further defines that the rotating shaft 51 and / or the connecting rod 52 can move along its direction on the basis of the specific embodiment 1 or the specific embodiment 2.

[0041] This structural limitation enables the detonating device of the present invention not only to determine the position within the circumferential surface, but also to adjust the position in the direction perpendicular to the circumferential surface, which enriches the explosion points and facilitates the acquisition of more experimental data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com