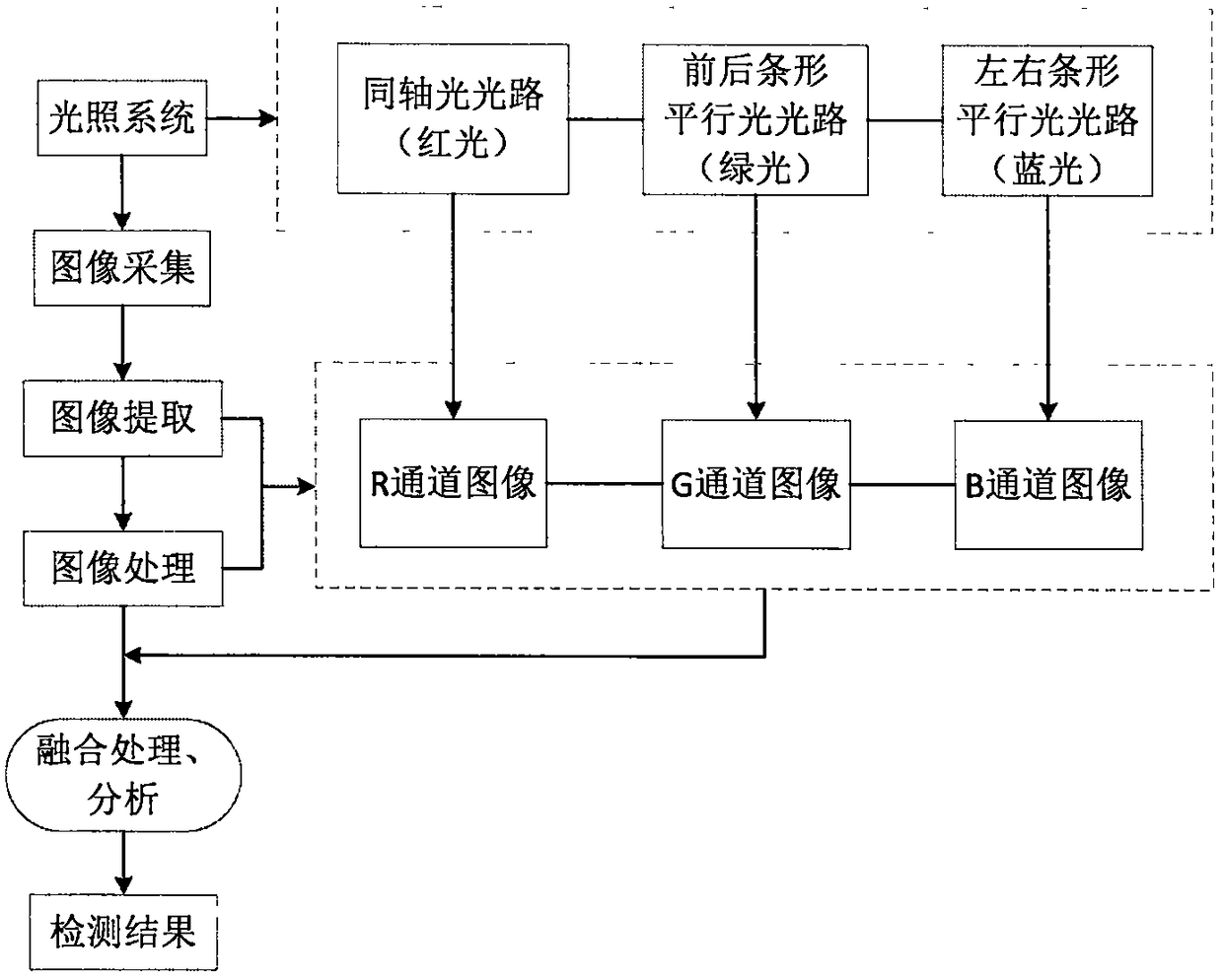

Color camera RGB image fusion visual inspection system and detection method

An RGB image and color camera technology, which is used in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of complex mechanical devices, many photographing processes and complex imaging devices, etc., to achieve simplified operation, simple structure, The effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

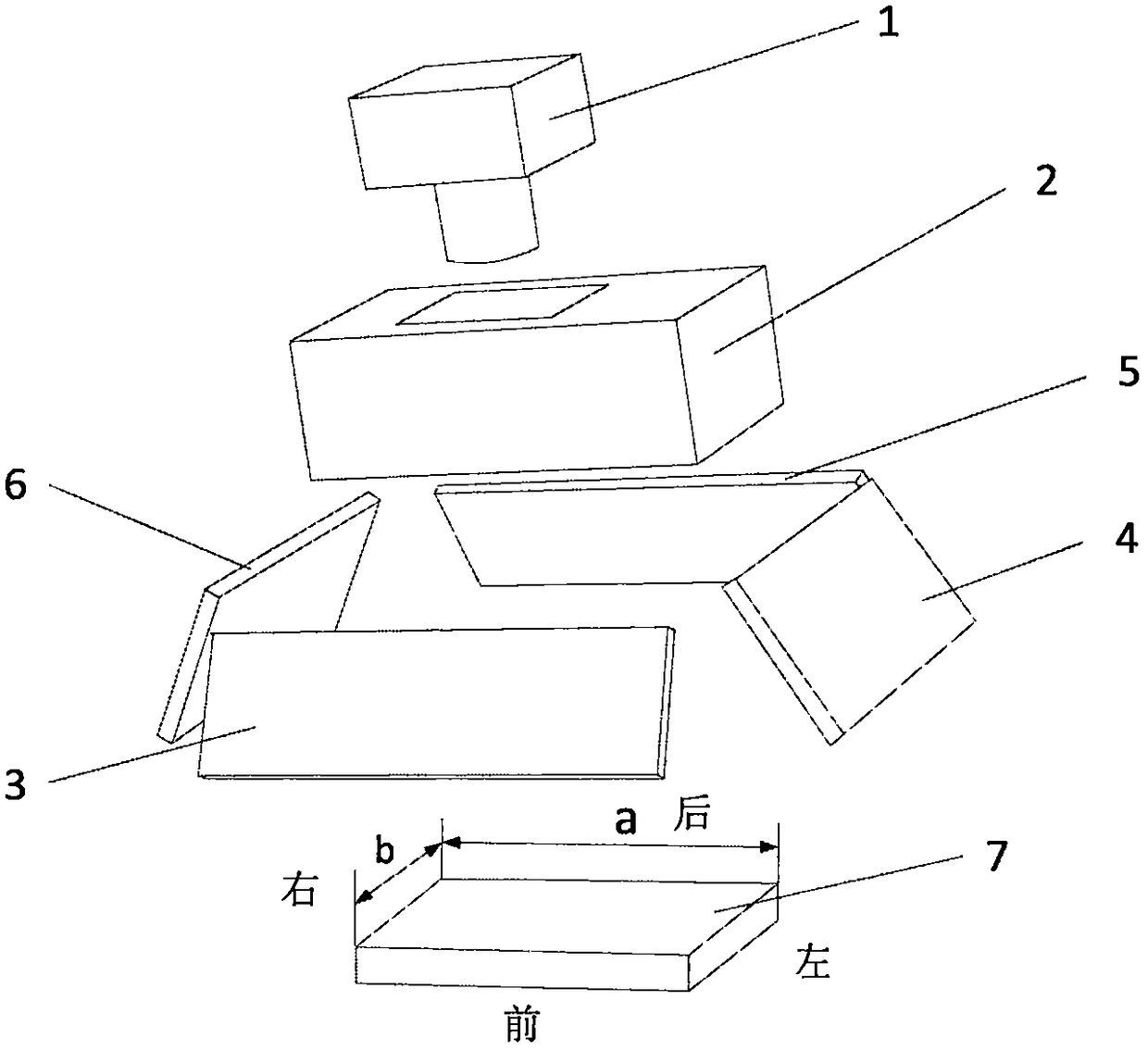

[0025] Such as figure 1 As shown, it is a schematic diagram of the detection system structure for defect detection of the object to be tested, in which 1 is a high-precision color camera, 2 is a coaxial light source, 3, 4, 5, and 6 are strip parallel light sources, and 7 is the object to be tested. When testing, the whole system is in a dark closed space. In the combined light illumination system, the strip-shaped parallel light sources 3, 4, 5, and 6 are respectively located above the front, left, rear, and right sides of the object to be tested, and the coaxial light source 2 is located on the directly above the object to be tested.

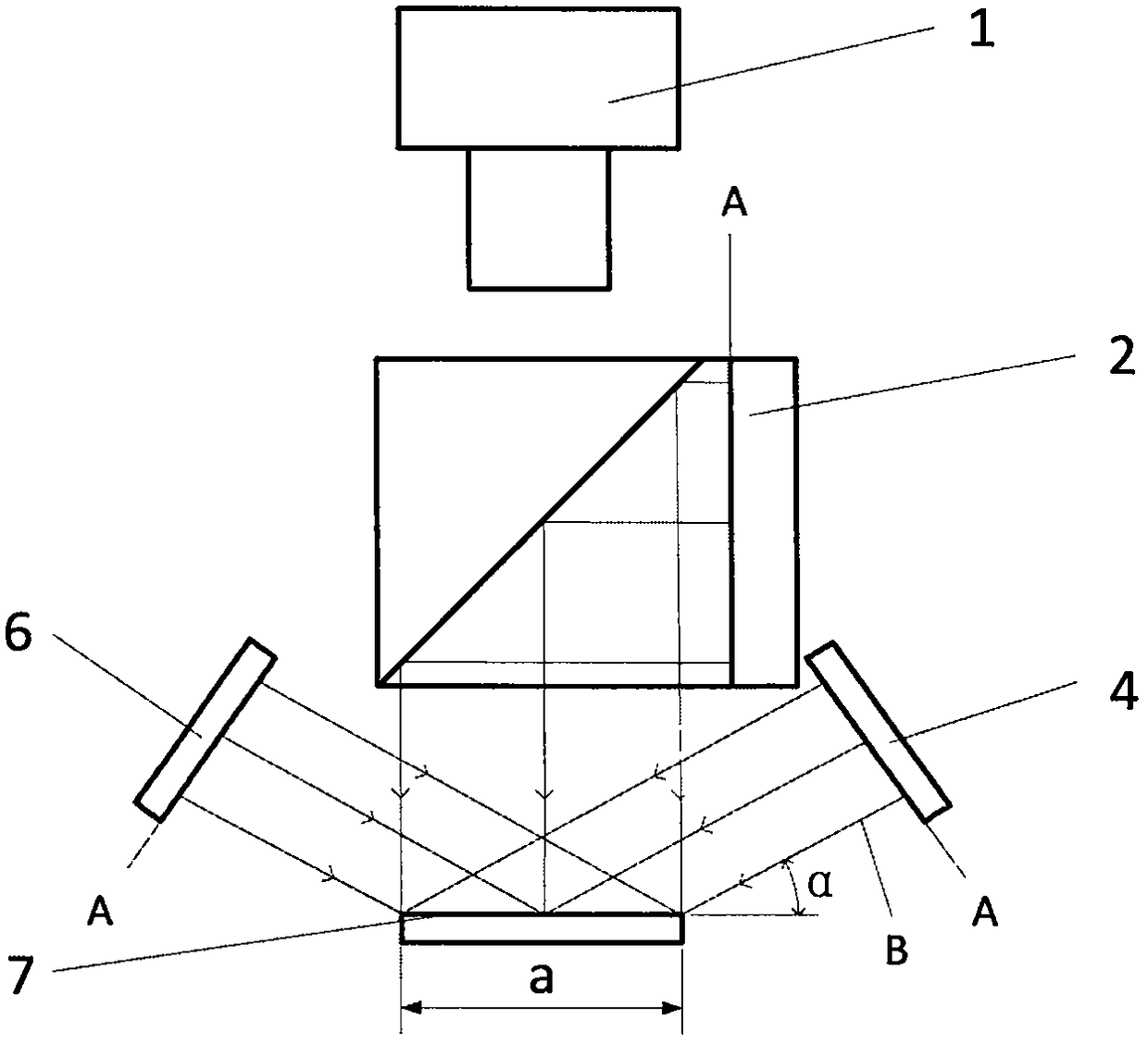

[0026] Such as image 3 As shown, it is a schematic diagram of the installation of the left and right strip parallel light sources and coaxial light sources viewed from front to back in the detection system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com