Detachable ultrasonic guided-wave sensor and mounting method thereof

An ultrasonic guided wave and sensor technology, applied in the field of sensors, can solve problems such as poor uniformity of energy coupling between sensors and structures, low structural life of bonded sensors, and inability to effectively detect, etc., to achieve strong standardization and avoid calibration, etc. work, ensuring consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

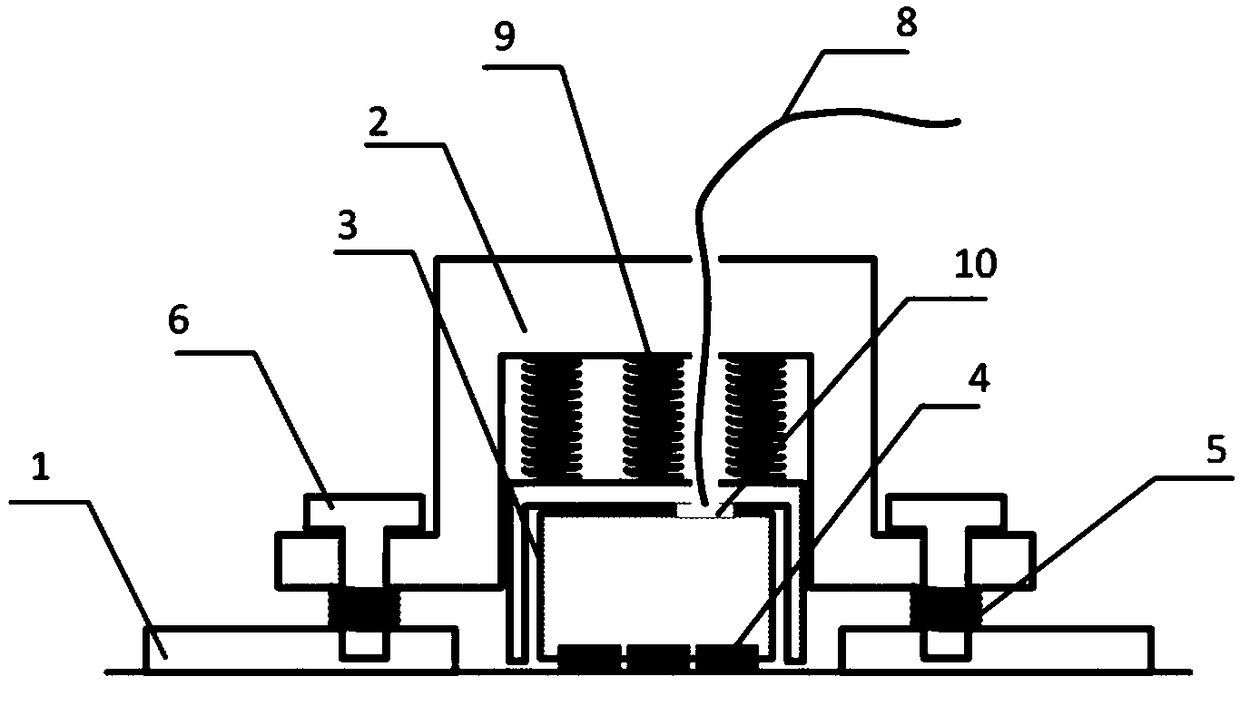

[0025] Embodiment 1, an installation method of a detachable ultrasonic guided wave sensor:

[0026] The base 1 is fixed on the surface of the structure. After the probe 3 is installed on the shell 2 through the lead interface 10, the shell 2 is installed on the base 1 with the bolt 6. When the bolt 6 is tightened, due to the gap between the probe 3 and the shell 2 Due to the function of the connected spring 9, the probe will be gradually pressed against the structure. After installation, the coupling between the probe and the structure is stable, and the corresponding data acquisition equipment is used to excite / receive ultrasonic guided waves to realize damage detection. After the work of the sensor is finished, the bolt 6 is unscrewed, the shell 2 is removed from the base 1, and the main body of the sensor is recovered.

Embodiment 2

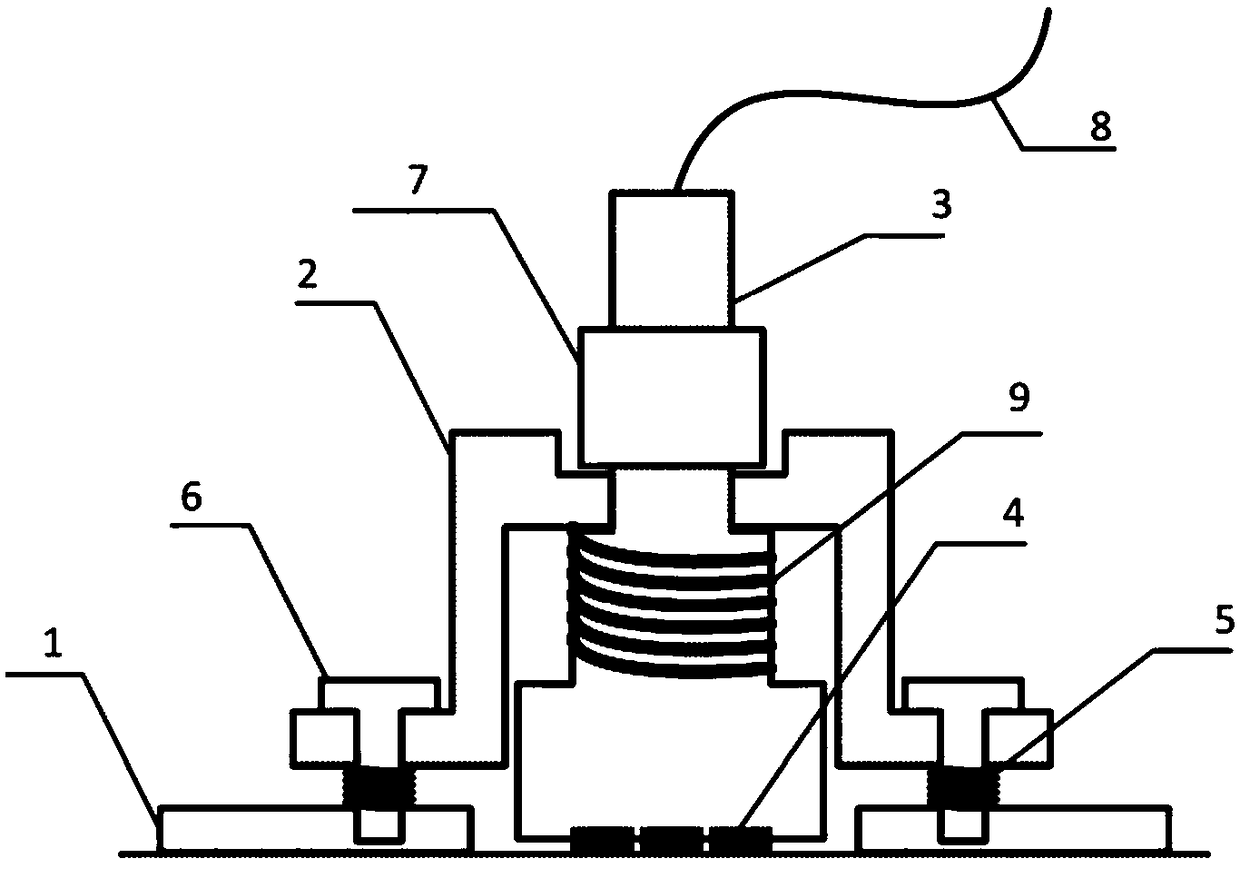

[0027] Embodiment 2, an installation method of a detachable ultrasonic guided wave sensor with a stop nut:

[0028] The base 1 is fixed on the surface of the structure. After the probe 3 is installed on the shell 2, the shell 2 is installed on the base 1 with the bolt 6. When the bolt 6 is tightened, due to the spring 9 connected between the probe and the shell and the limit Due to the function of the bit nut 7, the probe 3 will be gradually pressed against the structure. After installation, the coupling between the probe 3 and the structure is stable, and the corresponding data acquisition equipment is used to excite / receive ultrasonic guided waves to realize damage detection. After the work of the sensor is finished, the bolt 6 is unscrewed, the shell 2 is removed from the base 1, and the main body of the sensor is recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com