Method and device for simulating formation of reverse faults in laboratory

A reverse fault and laboratory technology, applied in the field of simulating the formation of reverse faults in the laboratory, can solve problems such as no reference significance and no consideration of the internal stress situation of fault stress changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

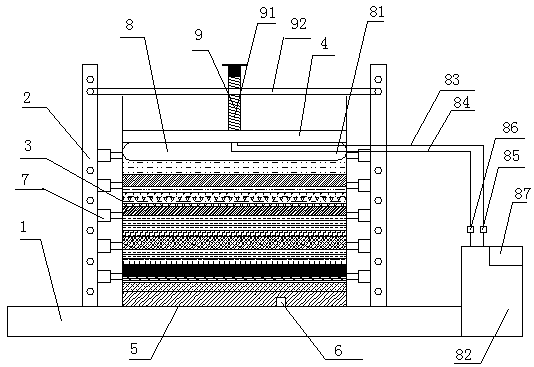

[0021] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0022] A method for simulating the formation of a reverse fault in a laboratory is realized through the following steps:

[0023] 1) Design a transparent experimental box, which can clearly observe the inside of the box;

[0024] 2) Design the upper pressure device and lateral pressure device to simulate the upper pressure and lateral extrusion force on the formation;

[0025] 3) Design an induction device to be placed at the bottom of the box, and then prepare similar simulated formation materials according to the proportion of the formation and lay them in the box;

[0026] 4) Install the designed upper pressurization device and lateral pressurization device on the box body, start the upper pressurization device and lateral pressurization device to apply pressure to similar simulated formation materials, and activate the induction device in the extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com