High-efficiency LED lighting lamp linear driving circuit

A technology of LED lighting and linear drive, applied in the field of LED lighting, can solve the problems of large surge current, low surge current, flickering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

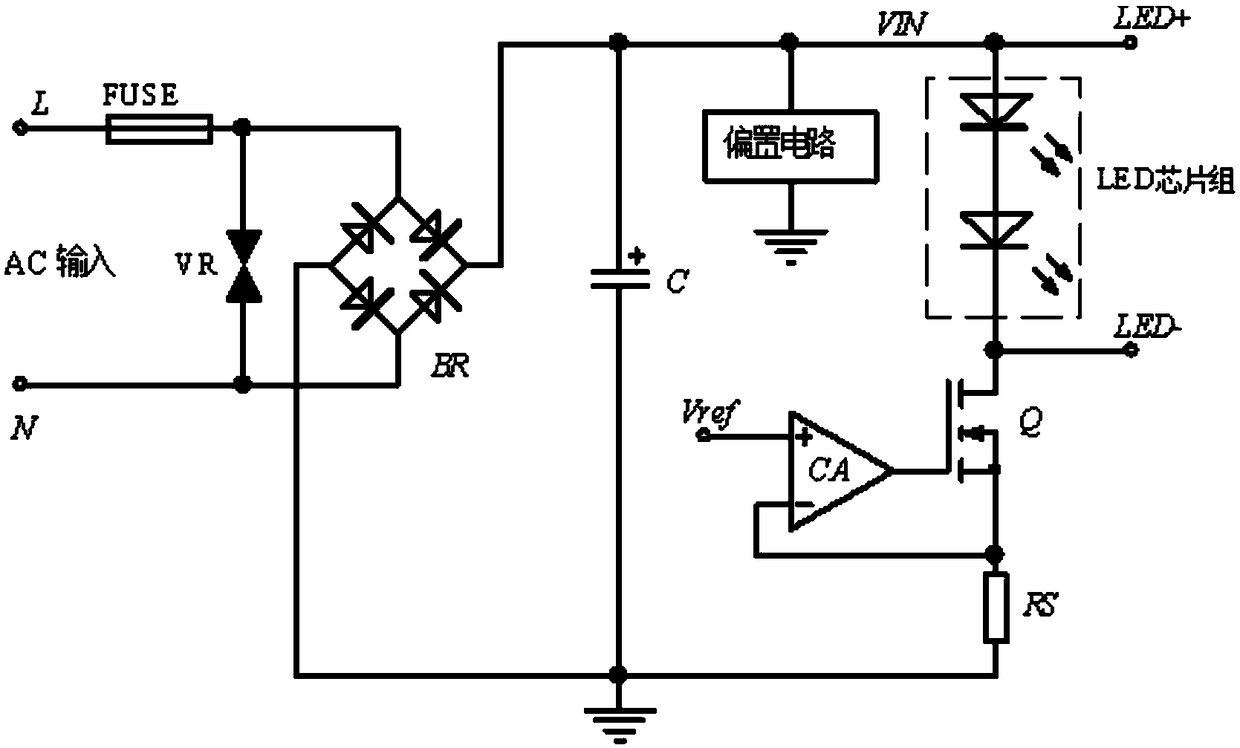

[0024] figure 2 It is a traditional small and medium power LED lighting circuit structure, with input protection circuit, bridge rectifier, constant current control circuit.

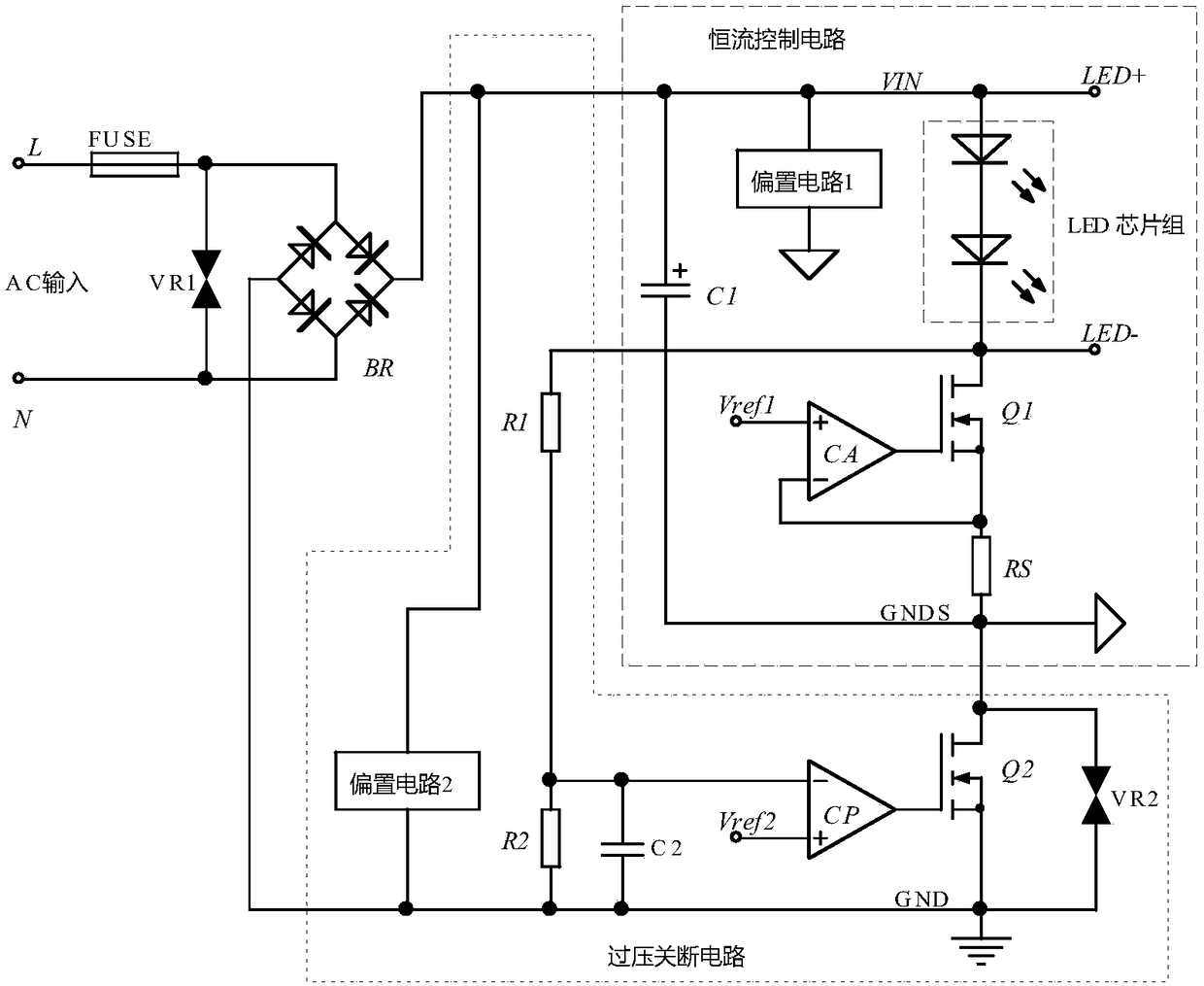

[0025] figure 1 The embodiment of the present invention is also a diagram for the abstract of the specification, including an input protection circuit, a bridge rectifier, a constant current control circuit, and an overvoltage shutdown circuit.

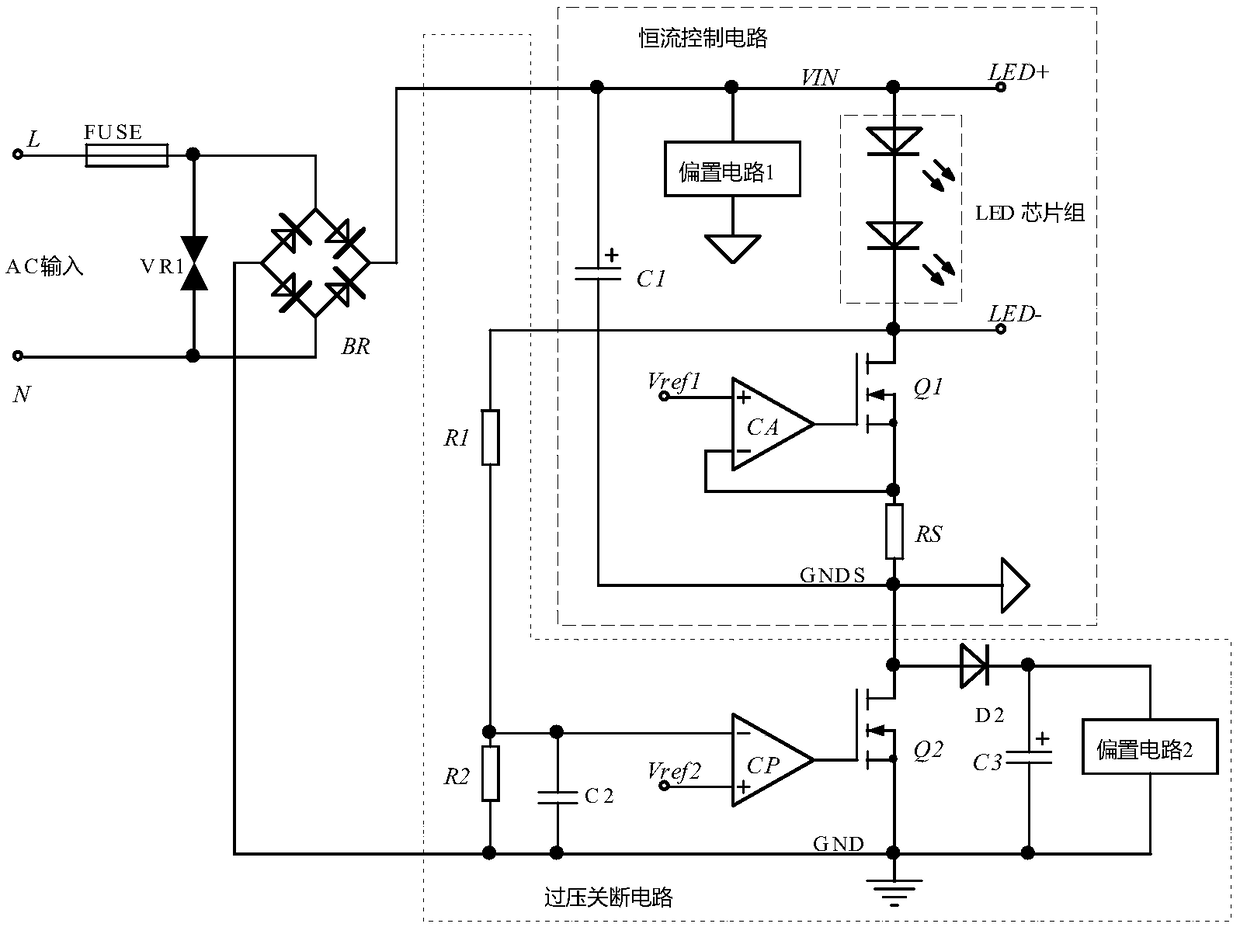

[0026] The constant current control circuit is composed of energy storage capacitor C1, series LED chipset, LED working current sampling resistor RS, current amplifier CA, reference voltage source, adjustment tube Q1 and bias circuit 1; the overvoltage shutdown The circuit is composed of the first voltage sampling resistor R1, the second voltage sampling resistor R2, the high-frequency filter capacitor C2, the comparator CP, the power switch tube Q2, the bias circuit 2, and the lightning protection device VR2; the input protection circuit consists of a fuse C...

Embodiment 2

[0038] In the following specific implementation process, it is assumed that in the 220V power supply state, in order to improve efficiency, the cut-off voltage V 2 Generally take (V F +30~40V), then the voltage V 2 Corresponding time:

[0039]

[0040] where U IN is the effective value of the input AC voltage, and f is the frequency of the AC voltage.

[0041] When the instantaneous value of the AC voltage is greater than the cut-off voltage V2, the switch tube Q2 is turned off, the energy storage capacitor C is discharged, and the terminal voltage V C Decrease, until the time t3, the voltage at the terminal C of the energy storage capacitor V C down to V 1 , to avoid flicker, obviously V 1 The minimum value is V F , then the capacity of the energy storage capacitor C.

[0042]

[0043] where P O is the output power of the lamp, and η is the efficiency of the driving power supply.

[0044] Assuming that the number of LED chips in series is 66, and the working v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com