Display heat dissipation structure and heat dissipation method

A technology of heat dissipation structure and display, applied in the direction of instrument, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problem of burnout of display, achieve the effect of improving efficiency and solving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

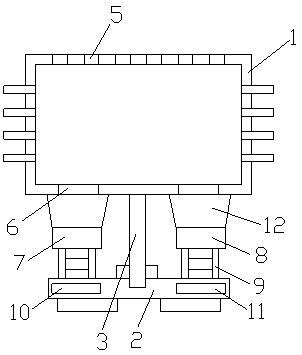

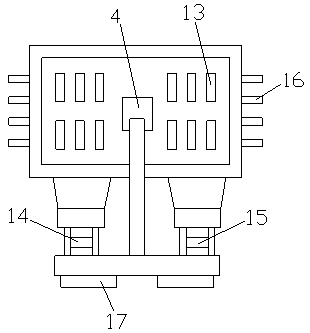

[0029] like Figure 1-2As shown, a heat dissipation structure of a display includes a housing 1 and a base 2, the base 2 is provided with a groove (not shown), the groove is provided with a support column 3, and the support column 3 is screwed into In the groove, the support column 3 is threadedly connected with the groove, and the back of the housing 1 is provided with an insertion part 4 that fits with the support column 3, and the insertion part 4 is fixedly connected with the back of the housing 1, and the support The column 3 is inserted into the insertion part 4, and the support column 3 is screwed to the insertion part 4. The top surface of the casing 1 is provided with cooling holes 5, and the cooling holes 5 are arranged at equal intervals. The bottom surface of the casing 1 Through-holes 6 are provided, and the through-holes 6 are symmetrically distributed. The first cooling fan 7 and the second cooling fan 8 are respectively arranged on the two sides of the base 2. ...

Embodiment 2

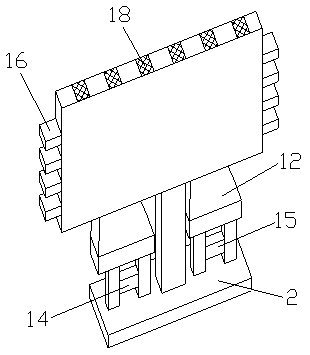

[0032] like Figure 1-3 As shown, a heat dissipation structure of a display includes a housing 1 and a base 2, the base 2 is provided with a groove (not shown), the groove is provided with a support column 3, and the support column 3 is screwed into In the groove, the support column 3 is threadedly connected with the groove, and the back of the housing 1 is provided with an insertion part 4 that fits with the support column 3, and the insertion part 4 is fixedly connected with the back of the housing 1, and the support The column 3 is inserted into the insertion part 4, and the support column 3 is screwed to the insertion part 4. The top surface of the casing 1 is provided with cooling holes 5, and the cooling holes 5 are arranged at equal intervals. The bottom surface of the casing 1 Through-holes 6 are provided, and the through-holes 6 are symmetrically distributed. The first cooling fan 7 and the second cooling fan 8 are respectively arranged on the two sides of the base 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com