Pulse detection device and manufacturing method thereof

A detection device and manufacturing method technology, applied in the field of medical devices, can solve problems such as the complex structure of the pulse detection device, and achieve the effects of good fit, improved accuracy, and reduced structural complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

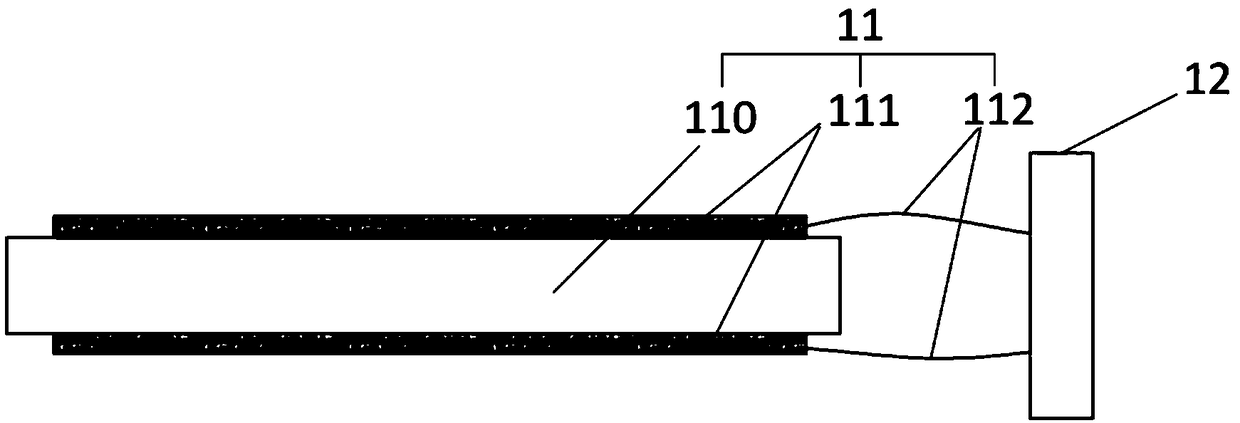

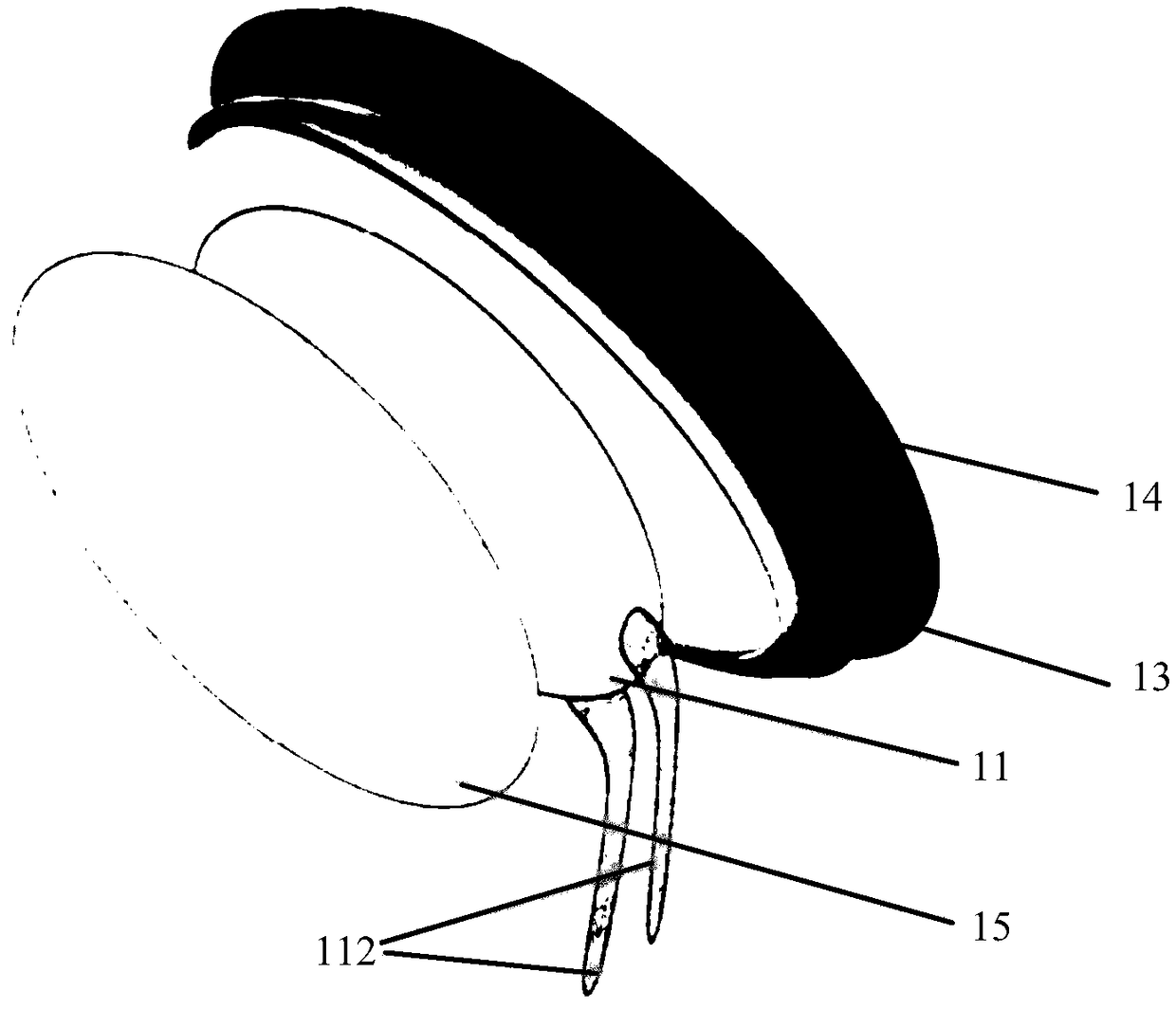

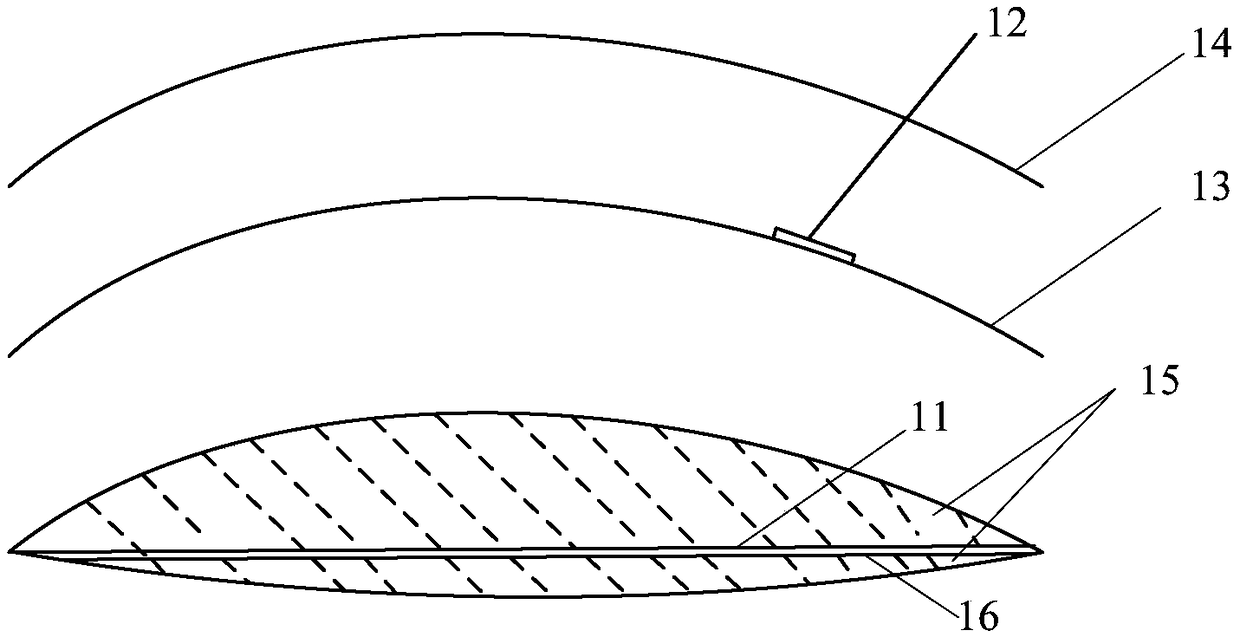

[0043] figure 1 It is a schematic structural diagram of the pulse detection device provided by Embodiment 1 of the present invention. The technical solution of this embodiment is applicable to the detection of the pulse based on the piezoelectric sensor, especially suitable for the detection of the pulse based on the flexible piezoelectric film. Such as figure 1 As shown, the pulse detection device includes: a piezoelectric sensing layer 11 and a data processing mechanism 12, the piezoelectric sensing layer 11 includes a flexible piezoelectric electret film 110, and is respectively arranged on the flexible piezoelectric electret film 110 1. Two metal electrodes 111 on the lower surface, the two metal electrodes 111 are used to output the amount of charge change when the flexible piezoelectric electret film 110 is deformed; the data processing mechanism 12 is used to connect the two metal electrodes 111 to receive the two metal electrodes 111 outputting the amount of change i...

Embodiment 2

[0063] Figure 5 It is a flow chart of the manufacturing method of the pulse detection device provided by Embodiment 2 of the present invention. The embodiment of the present invention is suitable for making a flexible pulse detection device. Such as Figure 5 As shown, the production method includes:

[0064] S101. Obtain a flexible piezoelectric electret film with a preset shape, and respectively set a metal electrode on the upper and lower surfaces of the flexible piezoelectric electret film, so as to output the deformation of the flexible piezoelectric electret film through the metal electrode. The amount of change in the amount of charge generated when .

[0065] Cut a piece of flexible piezoelectric electret film into a preset shape, such as a circle, and then figure 1 As shown, metal electrodes 111 are printed on the upper and lower surfaces respectively to obtain the piezoelectric sensing layer 11, that is, the piezoelectric sensor. Through the two metal electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com