Metal powder preparation device and method

A technology of metal powder and preparation equipment, which is applied in the field of metal powder preparation equipment and preparation, can solve the problems of metal powder satellite powder and other problems, achieve the effect of reducing the collision frequency and solving the phenomenon of satellite powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

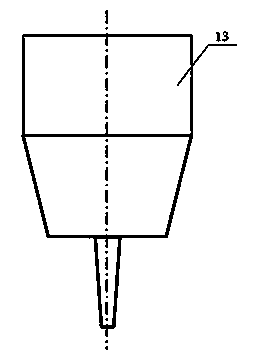

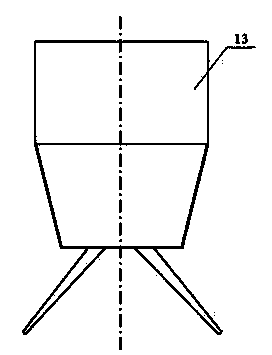

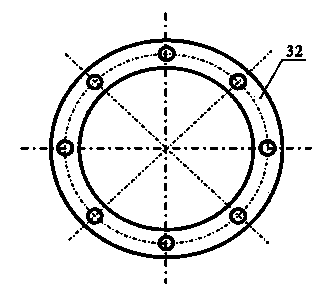

[0037] Such as figure 1 As shown, it is a schematic structural diagram of the metal powder preparation device provided by the present invention. The metal powder preparation device comprises a first chamber 1, a second chamber 2 and an atomization system arranged between the first chamber 1 and the second chamber 2, wherein:

[0038] The first chamber 1 is provided with a smelter 11 for melting metal, a tundish 12 for transferring molten metal and a draft pipe 13 for guiding the molten metal to flow out, and the outside of the smelter 11 and the tundish 12 are both The ring is provided with heating coils 14 for heating the melter 11 and the tundish 12 . Preferably, the smelter 11 is heated by medium frequency induction, and the tundish 12 is heated by resistance, so that the degree of superheat of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com