Lithium battery tab metal foil welding mechanism and welding method

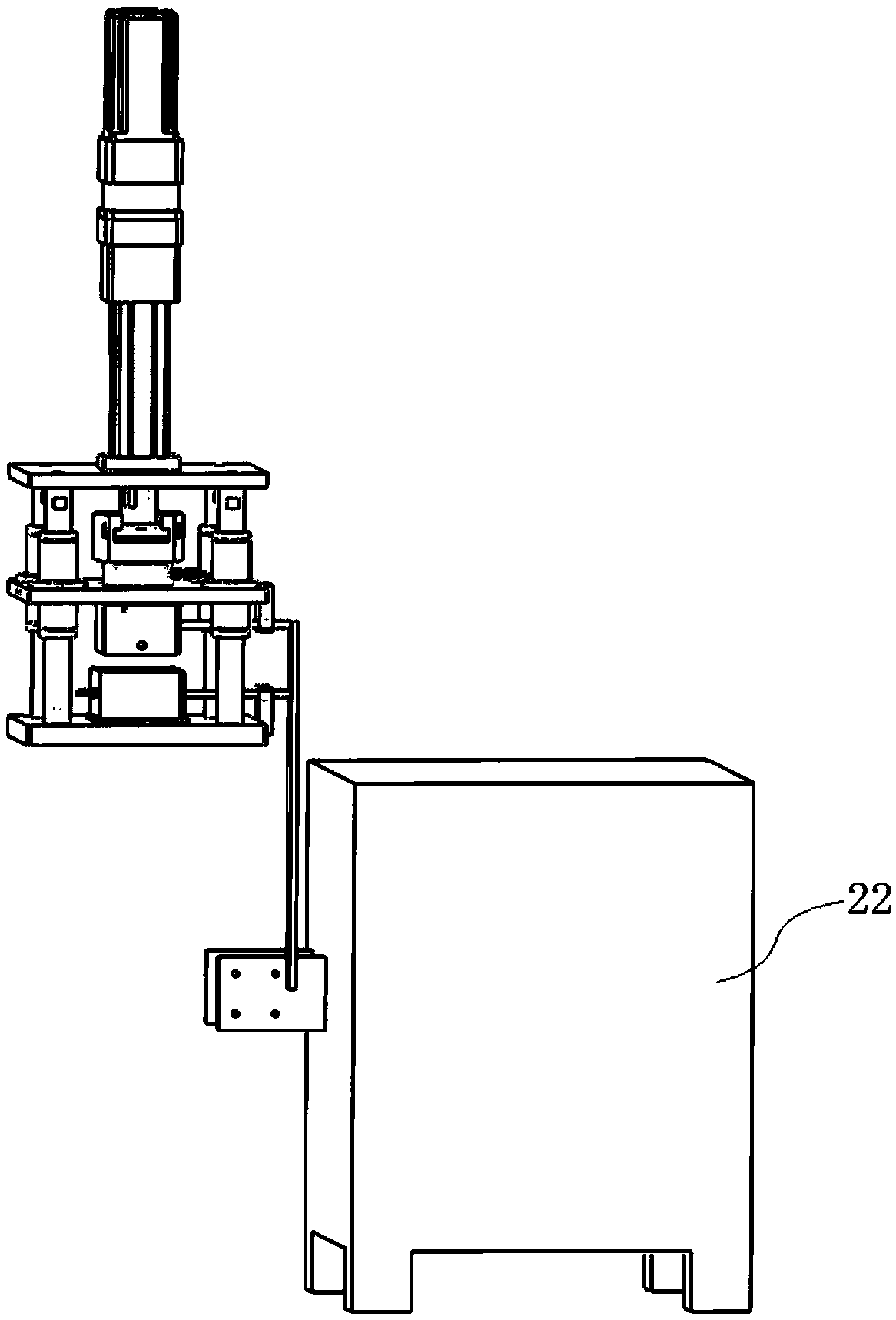

A welding mechanism and welding method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of inability to compact the welding area of metal foil, not conducive to reducing the reject rate of subsequent processes, and inability to improve production efficiency, etc. , to achieve the effect of improving welding efficiency and yield, reducing virtual welding and explosion phenomenon, and good anti-oxidation protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

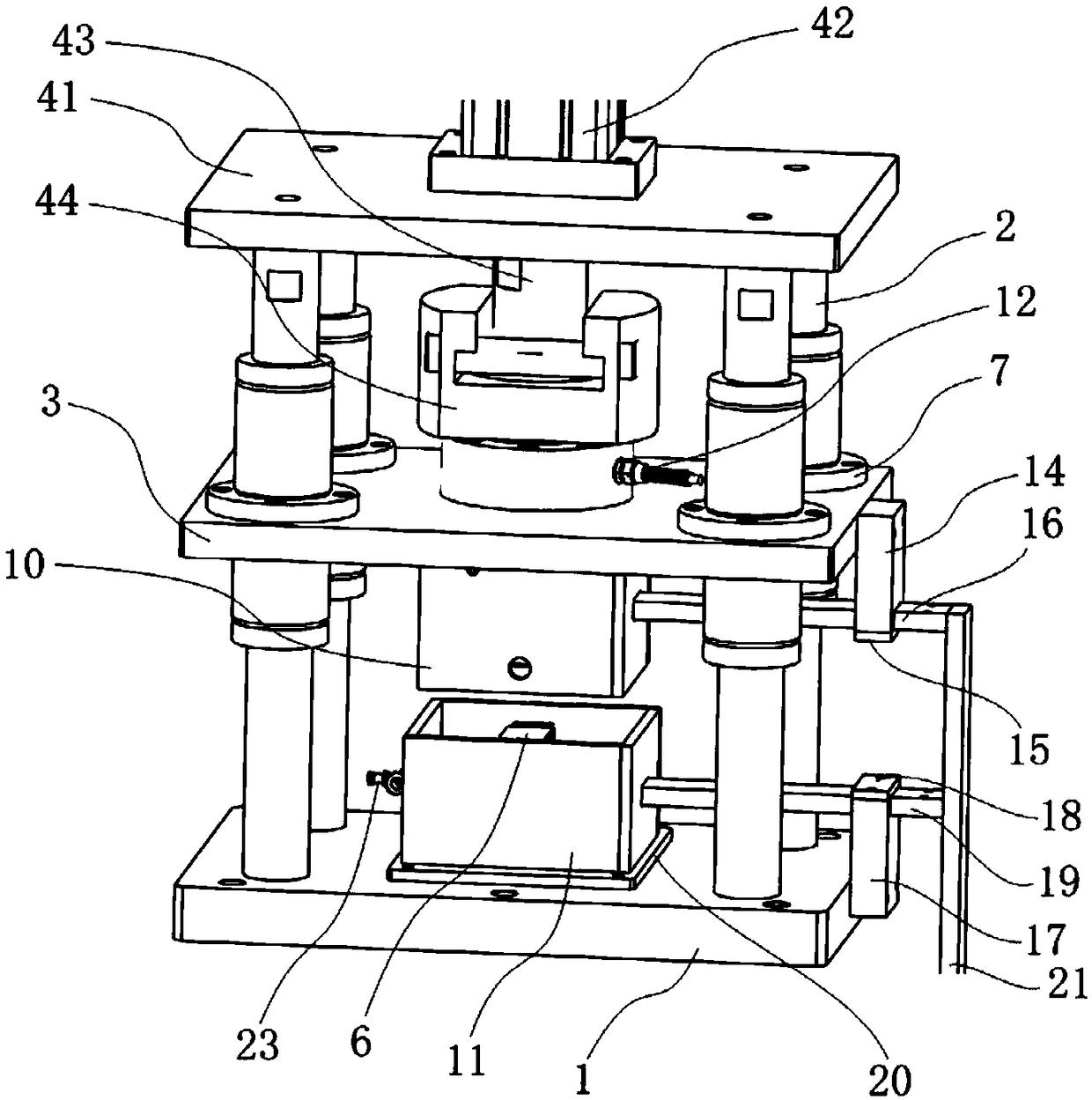

[0050] Use the above lithium battery tab metal foil welding mechanism to weld the welding metal foil, and the specific steps are as follows:

[0051] (1) Place the metal foil to be welded on the lower welding joint 6 of the lithium battery tab metal foil welding mechanism;

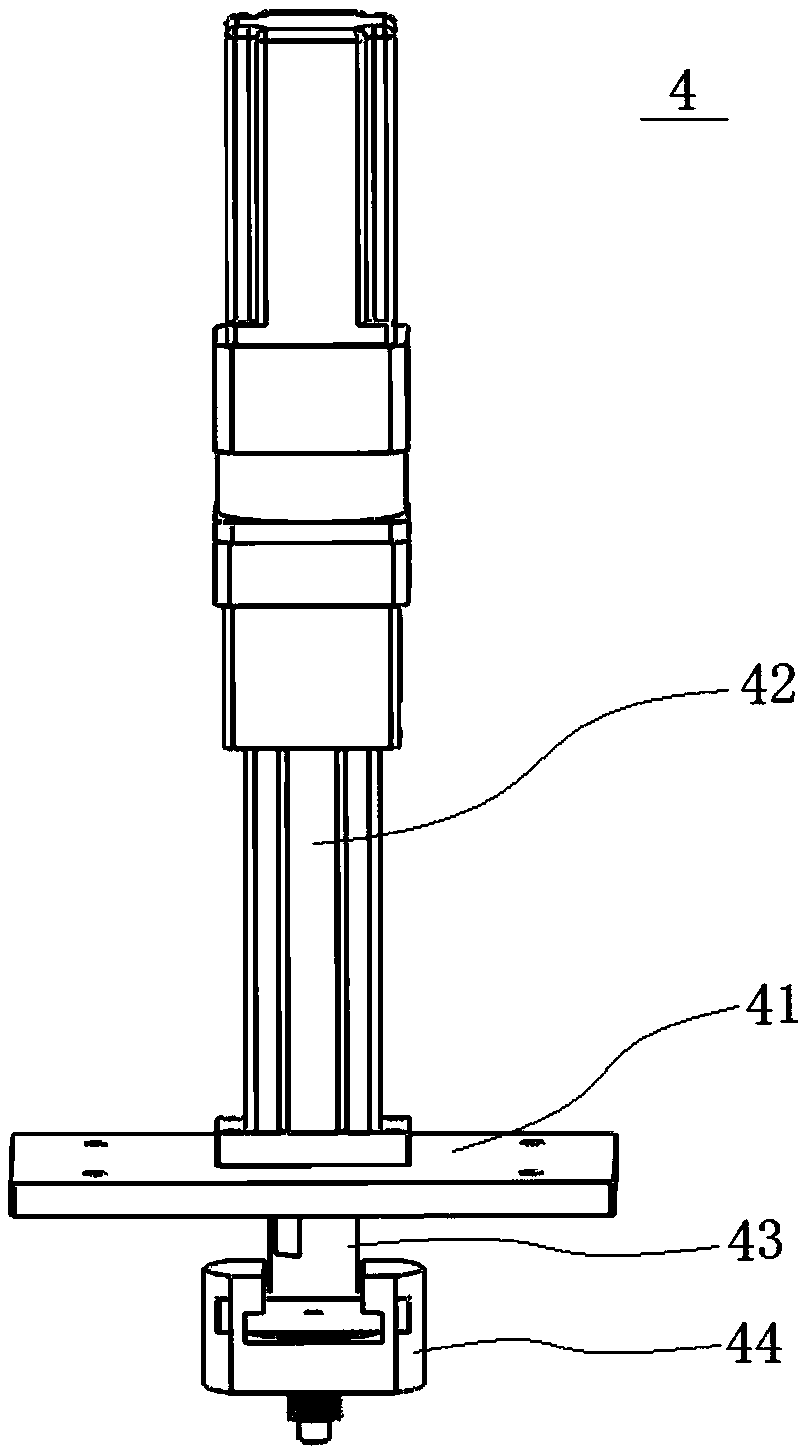

[0052] (2) Drive the servo electric cylinder 42 to push the guide plate 3 to move downward, and press and generate pressure between the upper welding head 5 and the lower welding head 6; at the same time, the upper protective cover 10 moves downward and forms a relatively closed relationship with the lower protective cover 11 Welding cavity, from the gas source through the gas joint 23 to the welding cavity into the welding shielding gas;

[0053] (3) When the pressure reaches the required value for welding, the power supply 22 is energized, and the 200A current is transmitted to the welding head through the copper wire strip 21, and the intermolecular diffusion of the foil material is accelerated under th...

Embodiment 2

[0057] Same as Example 1, wherein, the current passed in is 350A, the pressure between the welding heads is 1.0 times of the yield limit of the welding foil, and the welding temperature of the foil is measured by an infrared thermometer during the welding process, and the welding temperature is controlled 0.75 times the melting point of the foil.

[0058] No dust is produced during the welding process, and there are no false welding and explosion phenomena. The protective gas is introduced to avoid oxidation of the foil welding process.

Embodiment 3

[0060] Same as Example 1, wherein, the current passed in is 400A, the pressure between the welding heads is 0.9 times of the yield limit of the welding foil, and the welding temperature of the foil is measured by an infrared thermometer during the welding process, and the welding temperature is controlled 0.8 times the melting point of the foil.

[0061] No dust is produced during the welding process, and there are no false welding and explosion phenomena. The protective gas is introduced to avoid oxidation of the foil welding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com