Cutting method for solar-grade silicon wafer

A technology of solar-grade silicon wafer and cutting method, applied in the field of solar-grade silicon wafer cutting, can solve the problems of scrap and gap of silicon wafer, and achieve the effect of reducing edge gap, increasing contact length and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

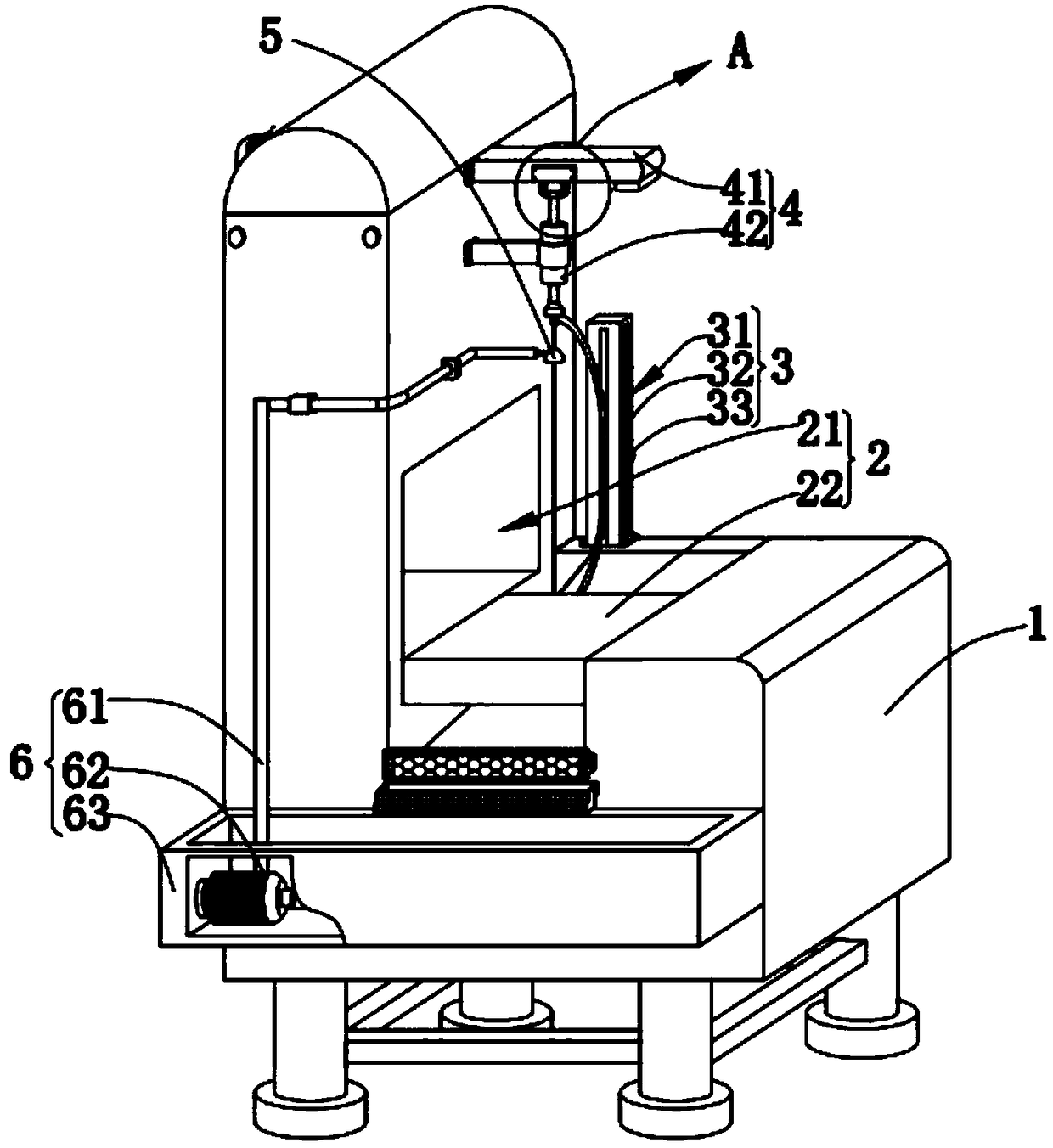

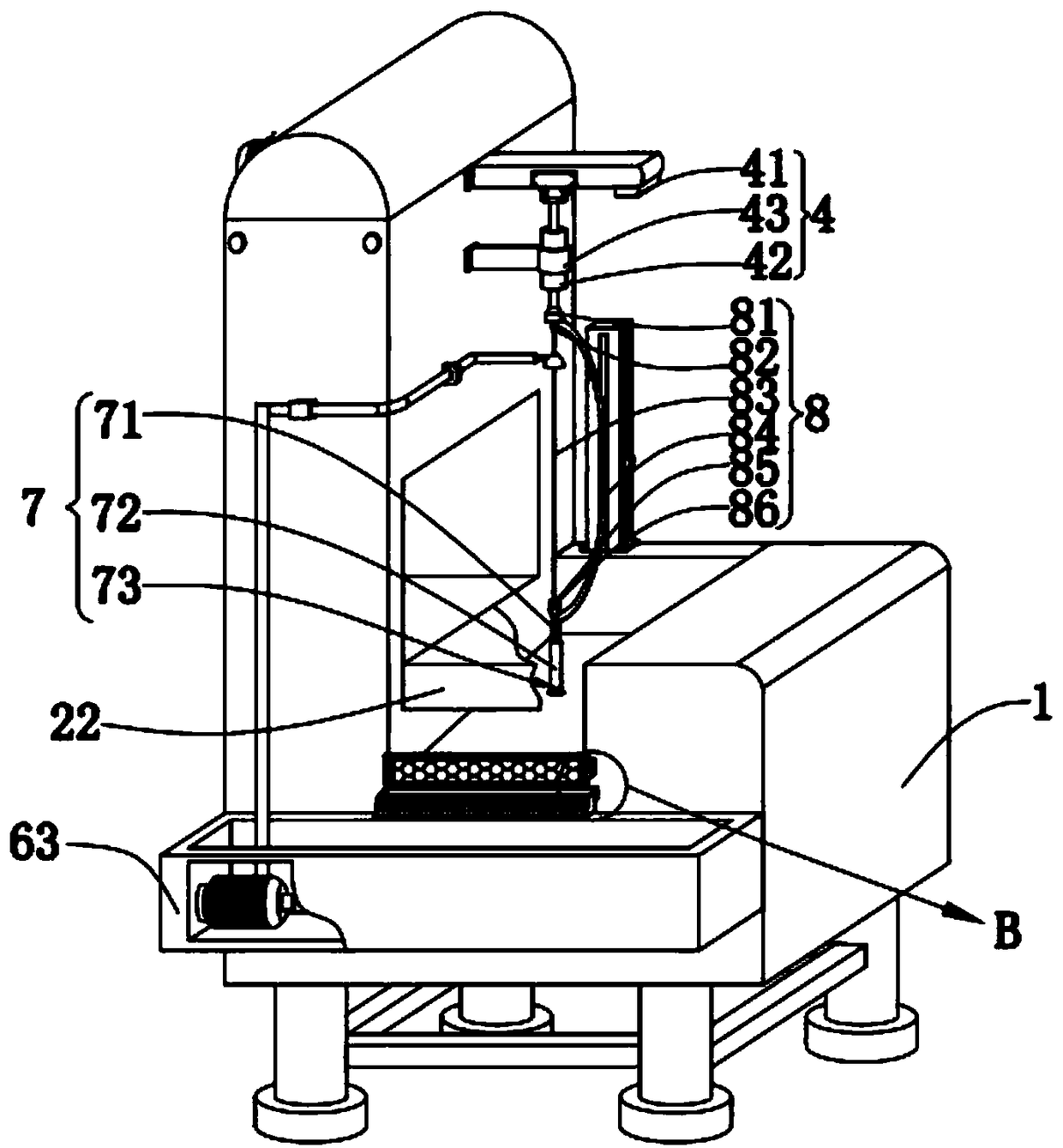

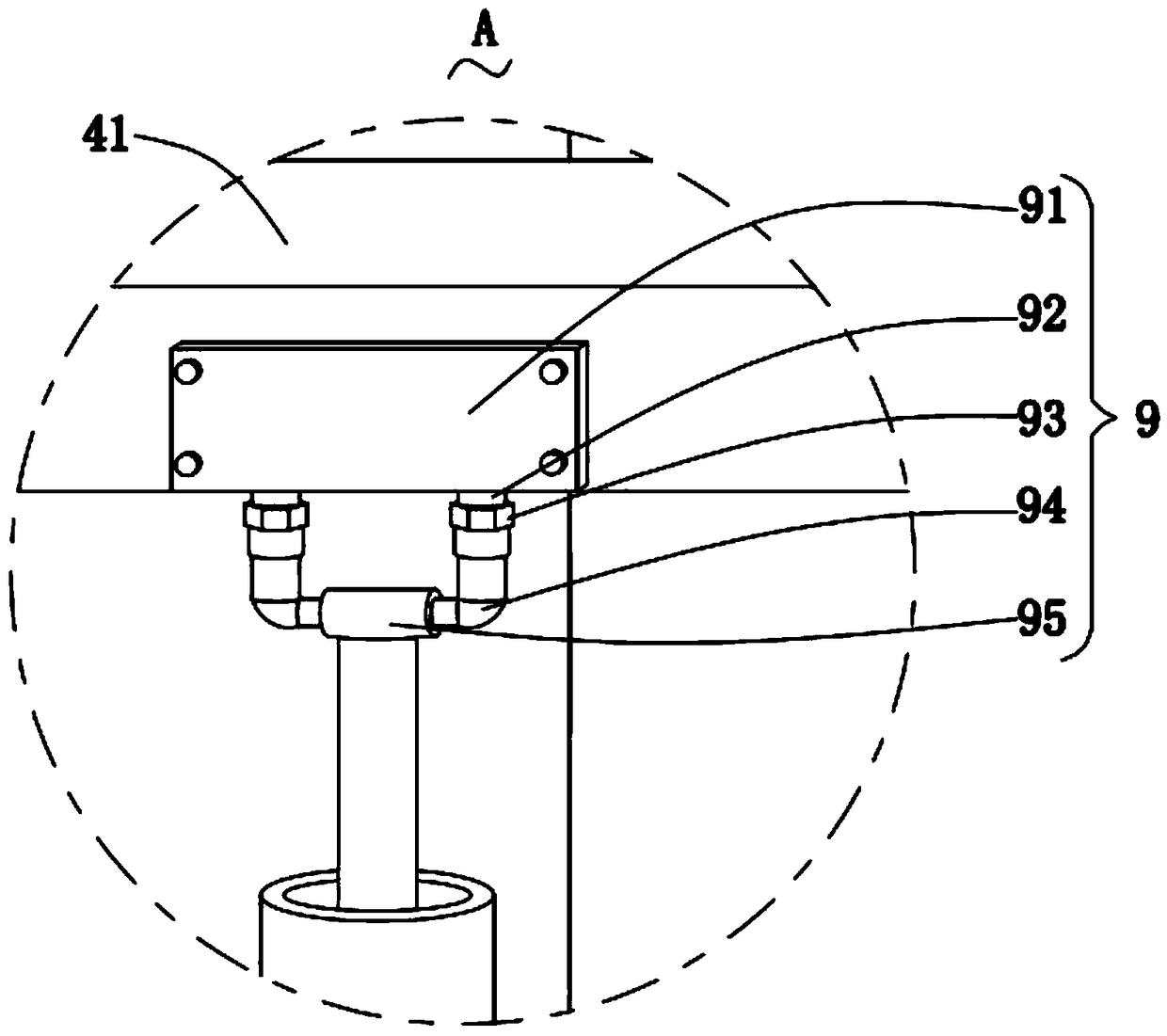

[0030] like figure 1 , figure 2 , image 3 and Figure 5 Shown, a kind of solar grade silicon chip cutting method of the present invention, this method comprises the following steps:

[0031] S1, electroplating a layer of metal film on the surface of the silicon wafer by electroplating;

[0032] S2, put the electroplated silicon wafer in S1 into the wire cutting equipment and cut it into pieces, and at the same time of wire cutting, use the silicon wafer as the anode, the carbon rod as the cathode, and the electroplating solution as the cutting fluid, and cut while electroplating;

[0033] S3, putting the silicon wafer cut in S2 into a pickling pool, and washing off the metal film on the surface of the silicon wafer;

[0034]The wire cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com