A block copolymer and absorbent comprising the block copolymer

A technology of block copolymers and absorbents, applied in the direction of reagents, educts, separation methods, etc., can solve the problems of absorbents that are affected by repeated use, cannot be completely removed, and inorganic carbonates cannot be decomposed and regenerated. Achieve excellent absorption capacity, high phase separation efficiency, and reduce regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Synthesis of polyquaternary ammonium salt type macroinitiator

[0041] Accurately weigh 1.5880g of dry benzylethyltrimethylammonium chloride and 0.067g of CuBr 2 , 125uL ligand PMDETA, 2.5ml DMF in a 50mL eggplant-shaped bottle, stir evenly, and seal. pass N 2 30min, three times of freezing-pumping-dissolving to remove the air in the eggplant-shaped bottle. After degassing, 0.0274g of ascorbic acid was dissolved in 2.5ml of ultrapure water, and then injected into the eggplant-shaped bottle at one time. Finally, 44uL of ethyl 2-bromoisobutyrate was added with a micro-injector, reacted at 30°C for 30h, and lyophilized after dialysis to obtain a polymer Quaternary ammonium salt type macroinitiator.

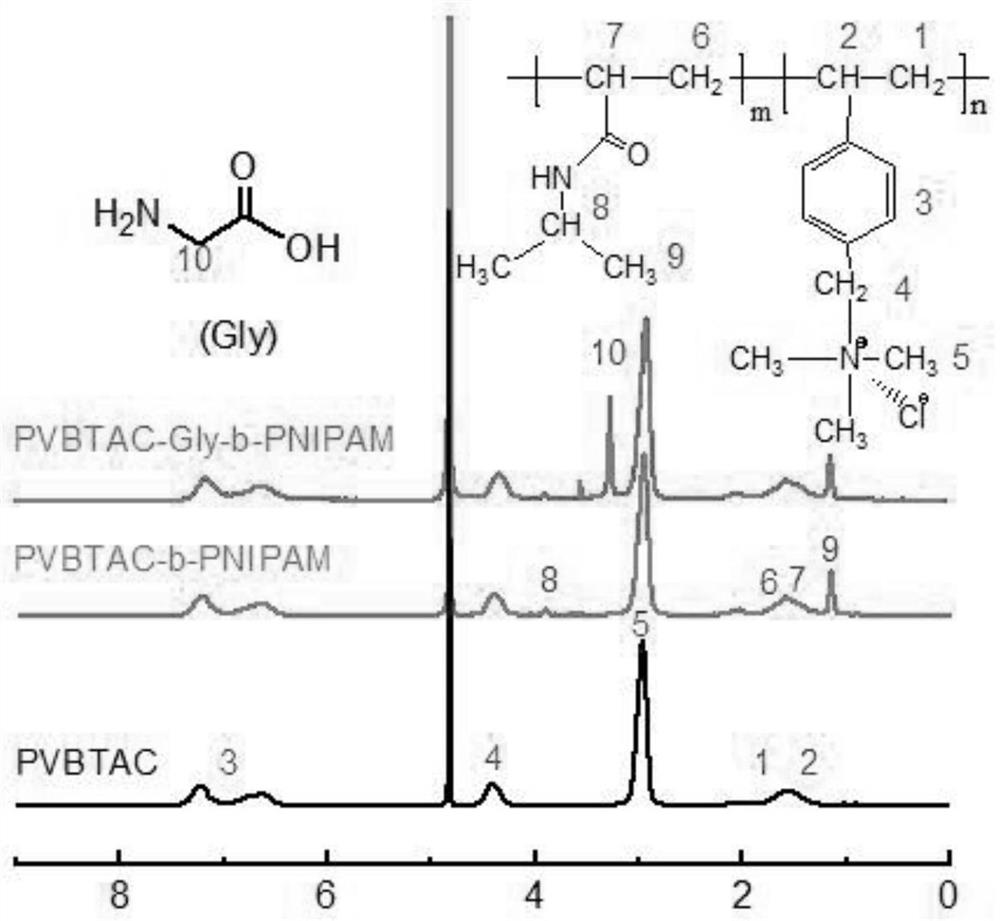

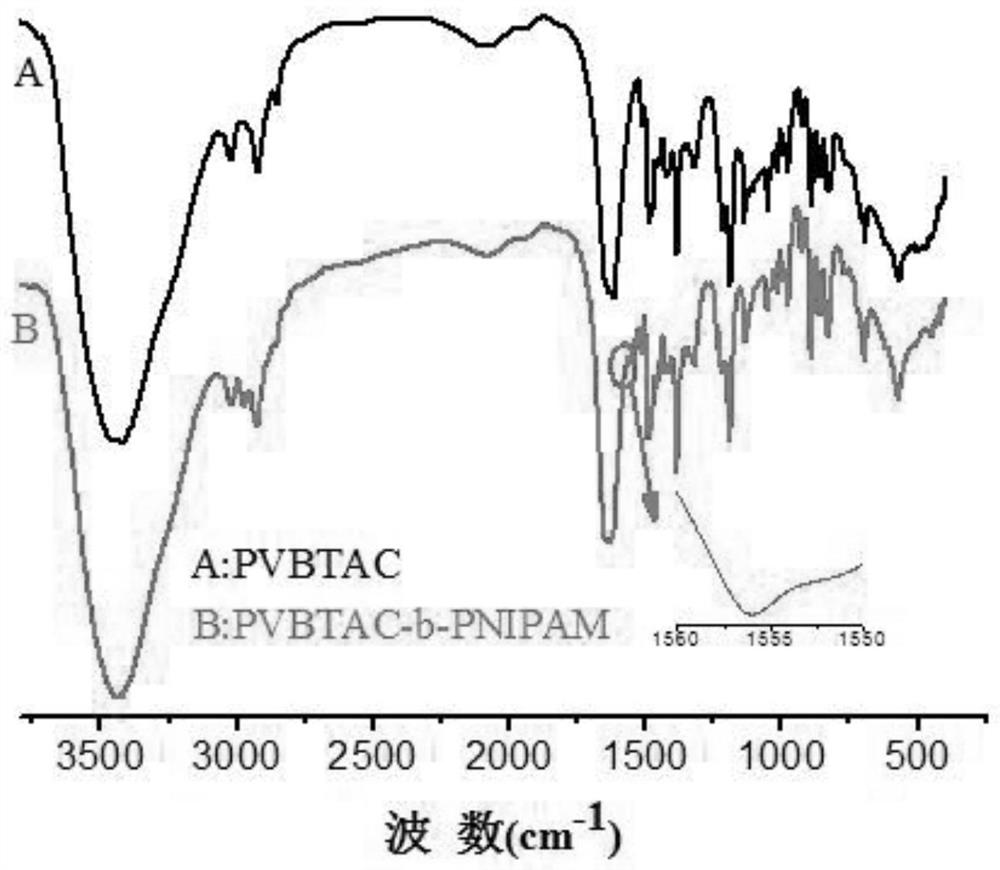

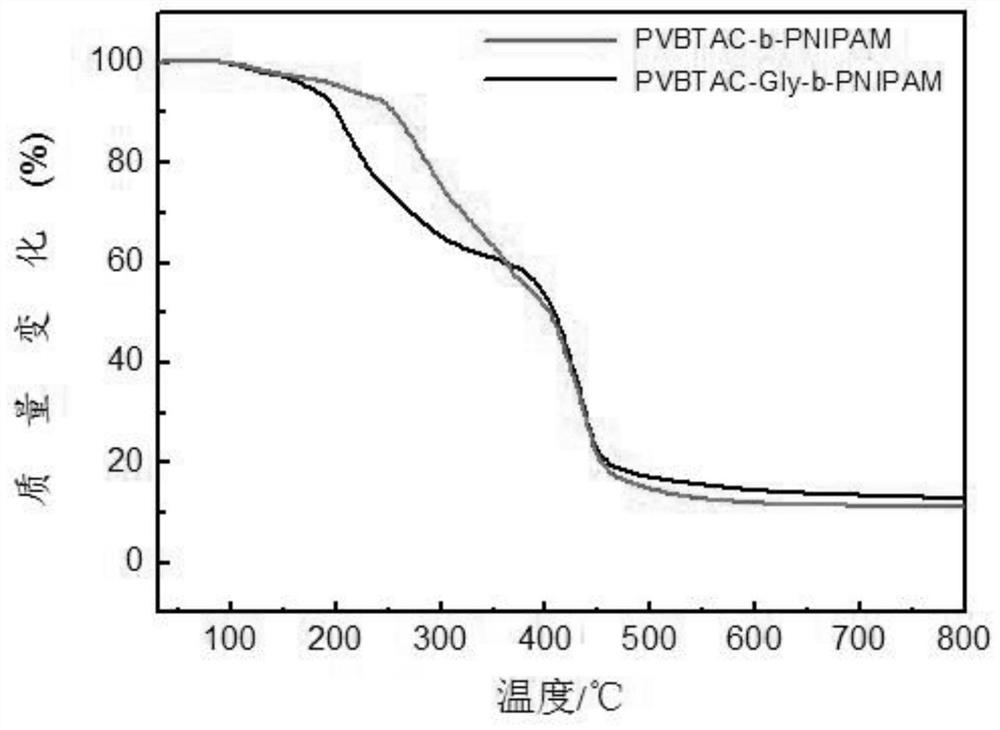

[0042] (2) Synthesis of thermosensitive block copolymer

[0043] In a 50ml eggplant-shaped bottle, 1.5g of polyquaternium-type macroinitiator, 0.6g of NIPAM, and 0.067g of CuBr were added in sequence. 2 , ME6TREN160.4uL, 3.3ml DMF, ultrasonic for 5min to completely d...

Embodiment 2

[0047] (1) Synthesis of polyquaternary ammonium salt type macroinitiator

[0048] Accurately weigh 1.4990g of dry benzylethyltrimethylammonium chloride, 0.1340g of CuBr2, 250uL of ligand PMDETA, and 2.5ml of DMF in a 50mL eggplant-shaped bottle, stir evenly and seal. pass N 2 30min, three times of freezing-pumping-dissolving to remove the air in the eggplant-shaped bottle. After degassing, 0.0528g of ascorbic acid was dissolved in 2.5ml of ultrapure water, and then injected into the eggplant-shaped bottle at one time. Finally, 88uL of ethyl 2-bromoisobutyrate was added with a micro-injector, reacted at 30°C for 30h, and lyophilized after dialysis to obtain a polymer Quaternary ammonium salt type macroinitiator.

[0049] (2) Synthesis of thermosensitive block copolymer

[0050] In a 50ml eggplant-shaped bottle, add 1.5g of polyquaternium-type macroinitiator, 0.6g of NIPAM, and 0.1340g of CuBr in turn. 2 , ME6TREN320.8uL, 3.3ml DMF, ultrasonic for 5min to completely dissolv...

Embodiment 3

[0054] (1) Synthesis of polyquaternary ammonium salt type macroinitiator

[0055] Accurately weigh and dry 1.4990g of benzylethyltrimethylammonium chloride, 0.2233g of CuBr2, 417uL of ligand PMDETA, and 2.5ml of DMF in a 50mL eggplant-shaped bottle, stir evenly, and seal. pass N 2 30min, three times of freezing-pumping-dissolving to remove the air in the eggplant-shaped bottle. After degassing, 0.0880g of ascorbic acid was dissolved in 2.5ml of ultrapure water and injected into the eggplant-shaped bottle at one time. Finally, 147uL of ethyl 2-bromoisobutyrate was added with a micro-injector, reacted at 30°C for 30h, and lyophilized after dialysis to obtain a polymer Quaternary ammonium salt type macroinitiator.

[0056] (2) Synthesis of thermosensitive block copolymer

[0057] In a 50ml eggplant-shaped bottle, 1.8g of polyquaternium-type macroinitiator, 0.6g of NIPAM, and 0.2680g of CuBr were added in sequence. 2 , ME6TREN641.6uL, 3.3ml DMF, ultrasonic for 5min to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com