Composite coating material and its preparation method and application

A composite coating and substrate technology, used in coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of aging and discoloration of coatings, and achieve strong adhesion, high flatness, and protective color paint. layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

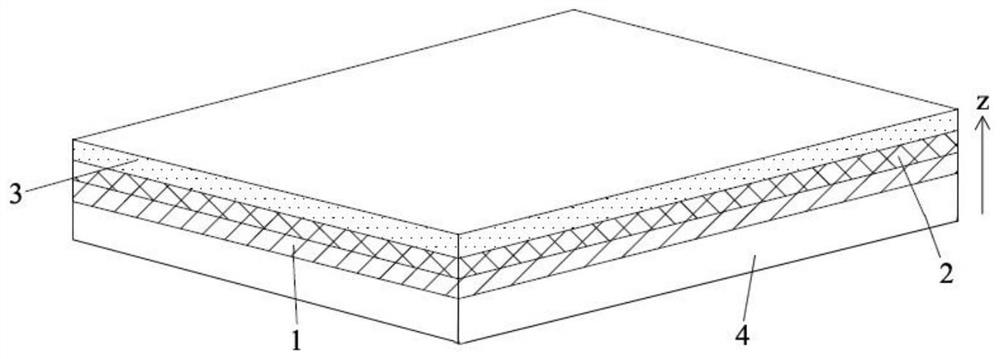

[0034] like figure 1 As shown, the first embodiment of the present disclosure provides a composite coating material, which includes:

[0035] Substrate 4;

[0036] Primer layer 1, it is formed on the surface of substrate 4;

[0037] The color paint layer 2, which is in contact with the primer layer 1; and

[0038] The topcoat layer 3 is formed on the opposite side of the basecoat layer 1 to the basecoat layer 1 .

[0039] In the composite coating material of the present disclosure, the primer layer 1, the color paint layer 2 and the top paint layer 3 have excellent anti-aging properties, are not easy to change color, and the primer layer 1, the color paint layer 2 and the top paint layer 3 Strong binding force, not easy to fall off.

[0040] In the present disclosure, primer layer 1 may be formed on substrate 4 . The material of the primer layer 1 includes: polyurethane acrylate, epoxy acrylate oligomer, resin monomer and additives. The primer layer 1 prepared by using t...

no. 2 approach

[0074] The second embodiment of the present disclosure provides a method for preparing the composite coating material according to the first embodiment of the present disclosure, which may include the following steps:

[0075] Provide base material 4 and primer layer 1, color paint layer 2 and the raw material of topcoat layer 3;

[0076] After mixing the raw materials, primer slurry, color paint slurry and topcoat slurry are respectively obtained;

[0077] The primer slurry, the color paint slurry and the topcoat slurry are sequentially composited on the substrate 4 to obtain a composite coating material.

[0078] Furthermore, when mixing the raw materials, the prepolymer, the resin monomer, and photoinitiators and other auxiliary agents can be mixed uniformly, and then the reactive diluent can be added for dilution.

[0079] Uniformly cover the primer slurry on the surface of the substrate 4, and cure it by ultraviolet light. Generally speaking, the curing time can be 10-30...

no. 3 approach

[0092] The third embodiment of the present disclosure provides an application of the composite coating material according to the present disclosure in a terminal device. Applying the composite coating material of the present disclosure to the surface of the terminal equipment shell can improve the problem of aging and discoloration on the surface of the terminal equipment shell. Even if the shell is made into a light-colored shell, the aging resistance is still excellent. Carry out the aging test according to the method of GB / T 1865-2009. Then according to the method of GB / T 11186, the color difference of the composite coating material with different aging time is calculated, so that when ΔE<1, the aging time of the composite coating material of the present disclosure can reach more than 300h. Therefore, the composite coating material of the present disclosure can impart a long-term colorful visual effect to the housing of the terminal device.

[0093] In addition, the termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com