Device for prolonging service life of plating solution

A technology of plating solution and service life, which is applied in the field of electroplating diamond wire saw production line, can solve the problems of plating solution mixing, no filtering system, increased cost, etc., and achieve the effect of simple structure, convenient operation and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

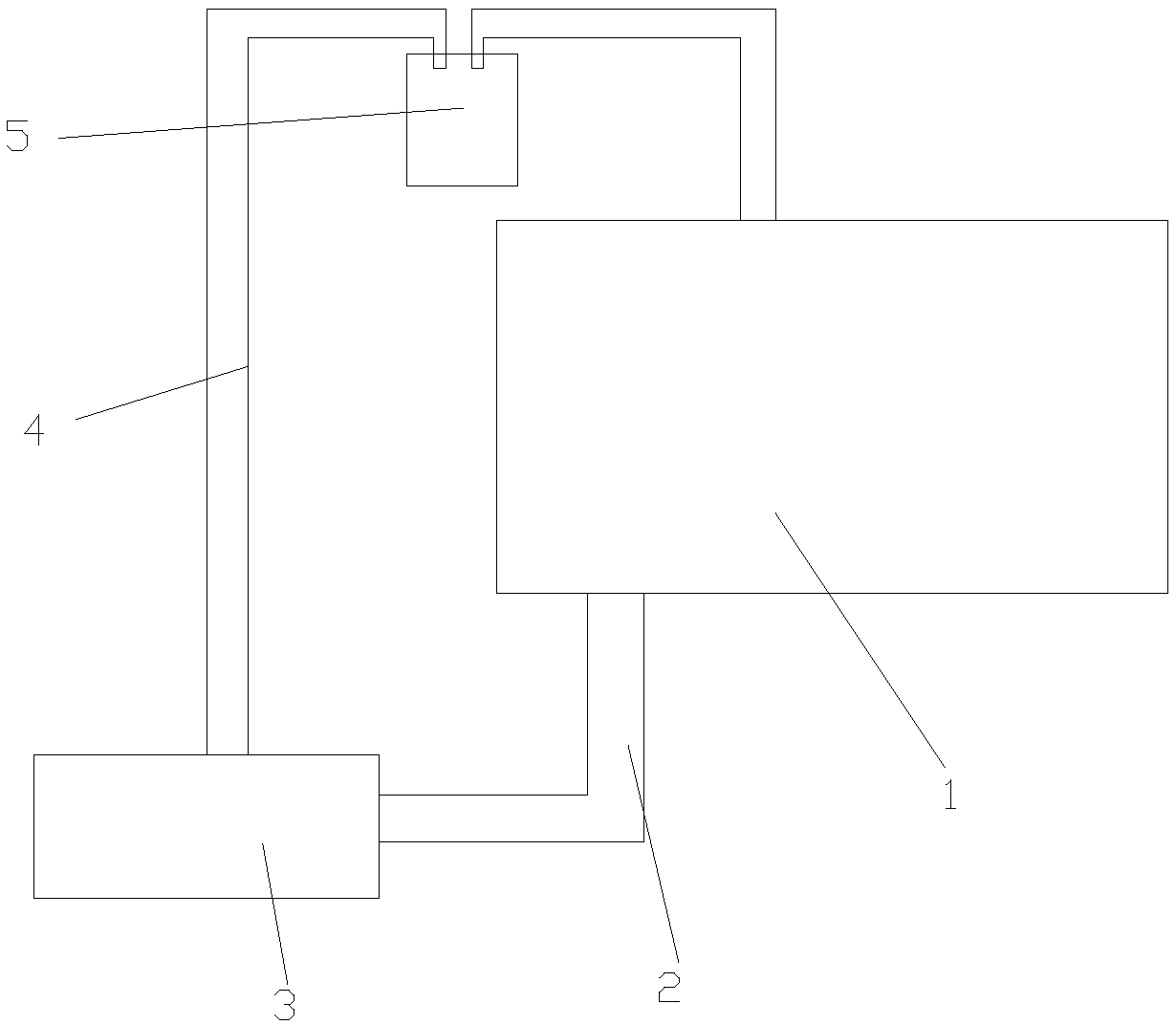

[0018] Embodiment 1 A kind of device that prolongs the service life of plating solution, electroplating comprises pre-plating tank 1, uses tool to increase a pipeline-2 at the bottom of pre-plating tank, and pipeline-connects magnetic pump 3, installs plating solution at the top of pre-plating tank simultaneously The water outlet, the magnetic pump is connected with the water outlet by pipeline two 4, and a filter bottle 5 is set up on the pipeline two.

[0019] Electroplating also includes a reinforcement tank, which has the same external connection structure as the pre-plating tank.

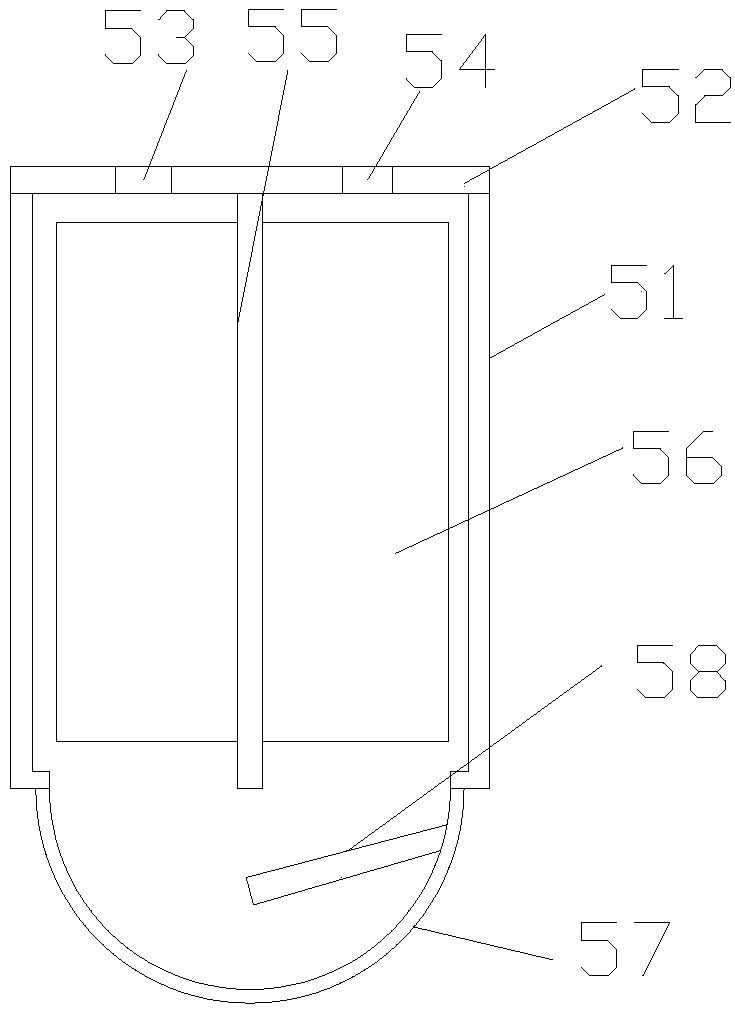

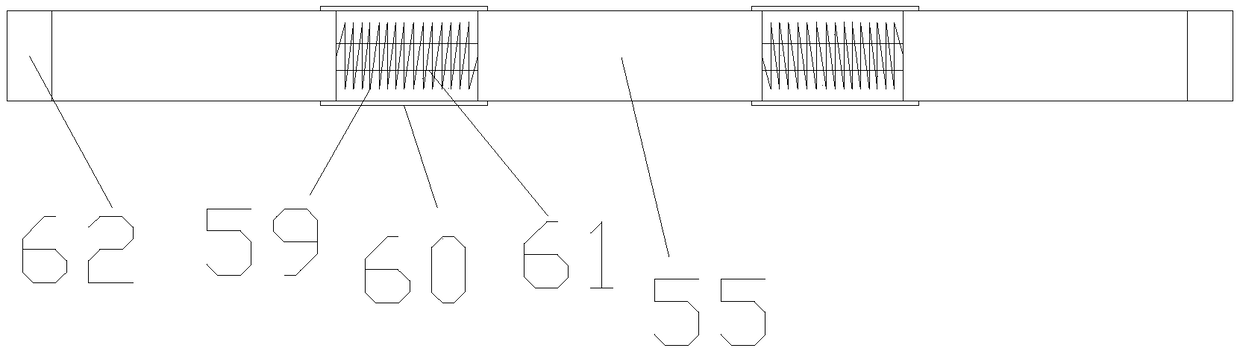

[0020] The filter bottle includes a bottle body 51, the upper end of the bottle body is open and is provided with a cover body 52, the cover body is provided with a water inlet 53 and a water outlet port 54, the inside of the bottle body is provided with a partition 55, and filter elements are provided on both sides of the partition board 56. The bottom of the bottle body is provided with a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com