Landslide and slope governing non-vertical type antiskid pile structure and installation method

An anti-slide pile, non-upright technology, applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of setting up firm connections, difficulty in coordination with the surrounding environment, unfavorable anti-slide pile support and retaining system, etc., to achieve shortening construction period, save money, and be beneficial to the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

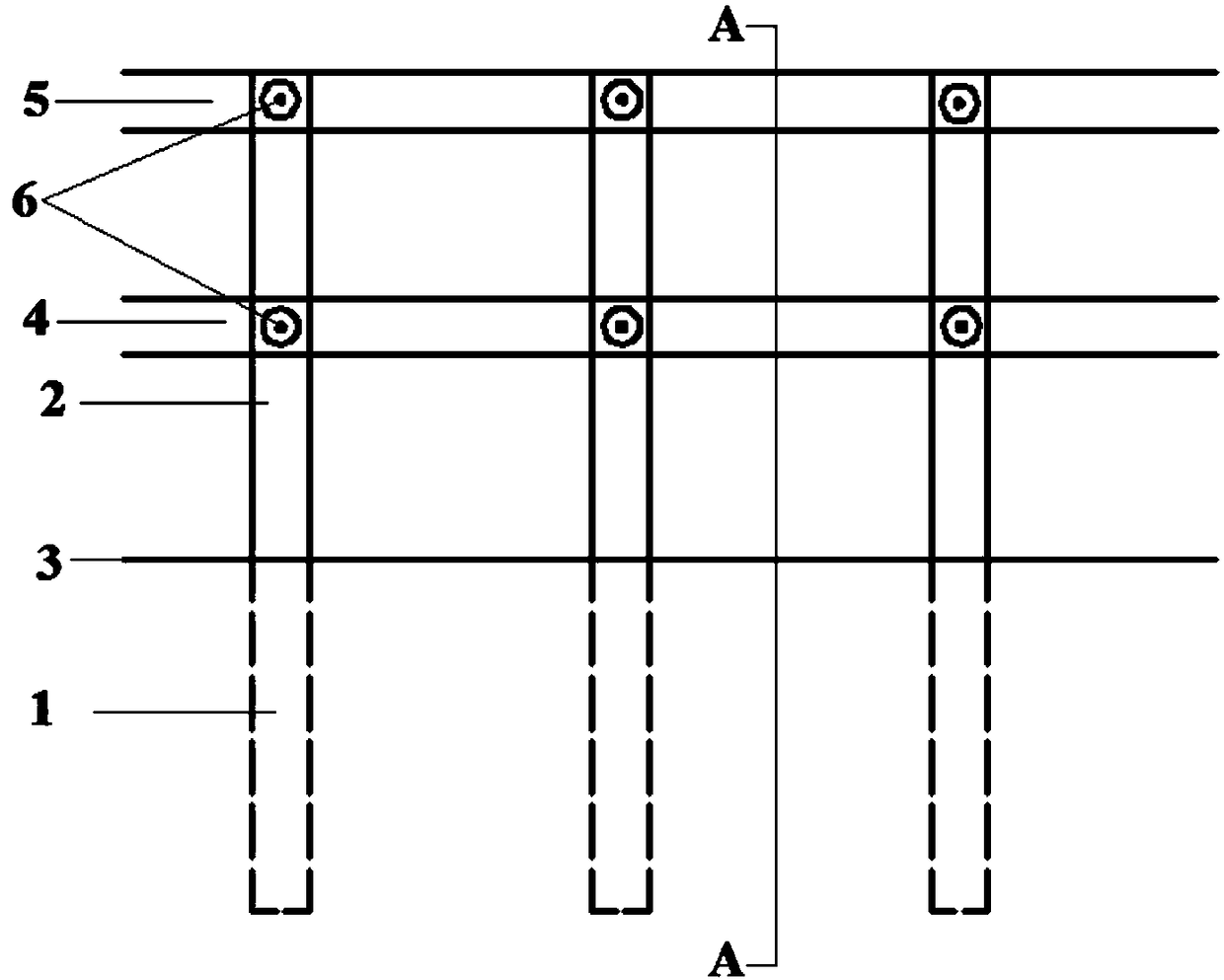

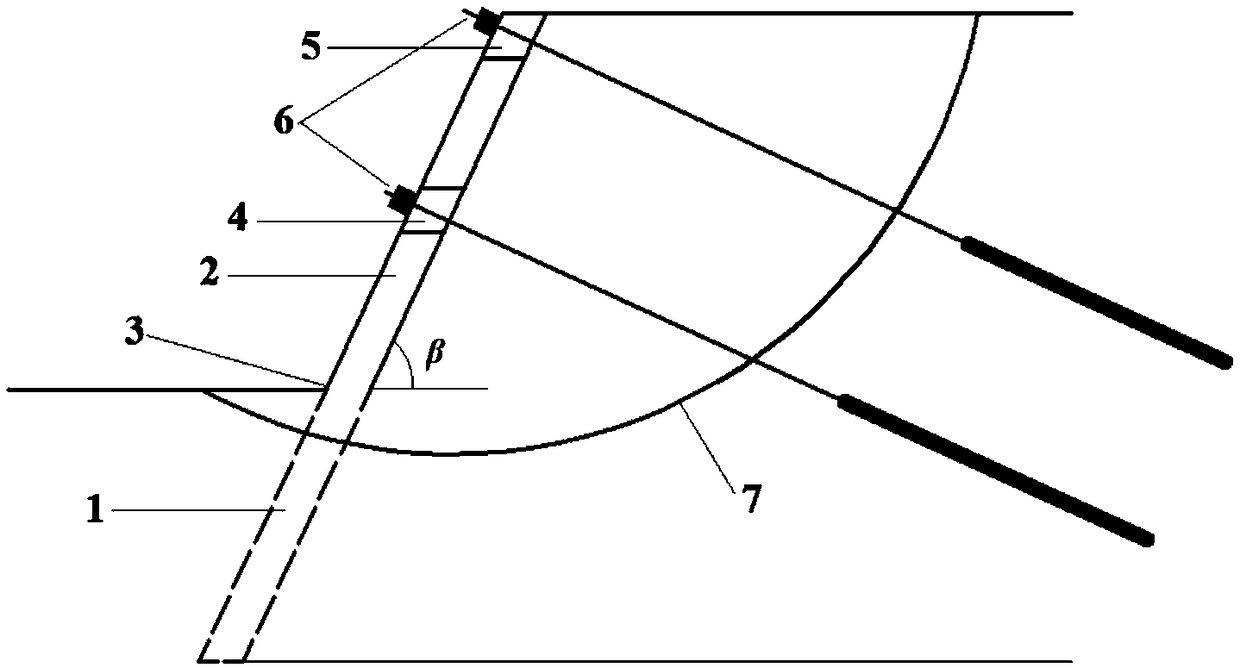

[0050] The invention provides a non-vertical anti-slide pile structure for landslide and slope control, see Figure 1-2 , including: non-vertical anti-slide piles; the non-vertical anti-slide piles include: non-vertical anti-slide pile anchorage section 1 and non-vertical anti-slide pile body non-anchor section 2; the non-vertical anti-slide pile The anchorage section 1 of the anti-slide pile body is arranged obliquely in the stable rock and soil body before the slope according to the slope angle β, and the non-anchor section 2 of the non-vertical anti-slide pile body is arranged on the slope surface of the landslide, figure 1 Also marked with the landslide slope foot line 3, sliding surface 7, landslide slope angle β.

[0051] The non-vertical anti-slide piles are provided with crossbeams 4 between piles, and the top of the non-vertical anti-slide piles is provided with a pile crown beam 5; the non-vertical anti-slide piles and the crossbeams 4, A pre-embedded plastic casing...

Embodiment 2

[0060] On the other hand, a non-vertical anti-slide pile structure installation method for landslide and slope treatment is provided, including:

[0061] Step 1. According to the survey data, collect and investigate the landslide type, scale, landslide body thickness, landslide perimeter, sliding surface type, sliding surface spatial position, sliding main axis and rock and soil physical and mechanical parameters within the scope of the landslide;

[0062] Step 2. According to the data collected and investigated in step 1, calculate the landslide thrust according to the mechanical model recommended by the current code;

[0063] Step 3, carry out the design of geometric parameters such as pile length, anchor length, pile spacing and pile body section size according to the landslide thrust calculated in step 2;

[0064] Step 4. According to the design plan drawn up in step 3, the non-vertical anti-slide pile and the rock and soil within the influence range of the landslide are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com