A Flywheel-Based Hybrid Mechanical System for Excavators

A mechanical hybrid and power system technology, applied in earth movers/shovels, construction, etc., can solve problems such as inconvenient installation of accumulators, influence of boom falling speed, pressure rise, etc., and achieve significant energy saving effects and improve Energy utilization efficiency and the effect of avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

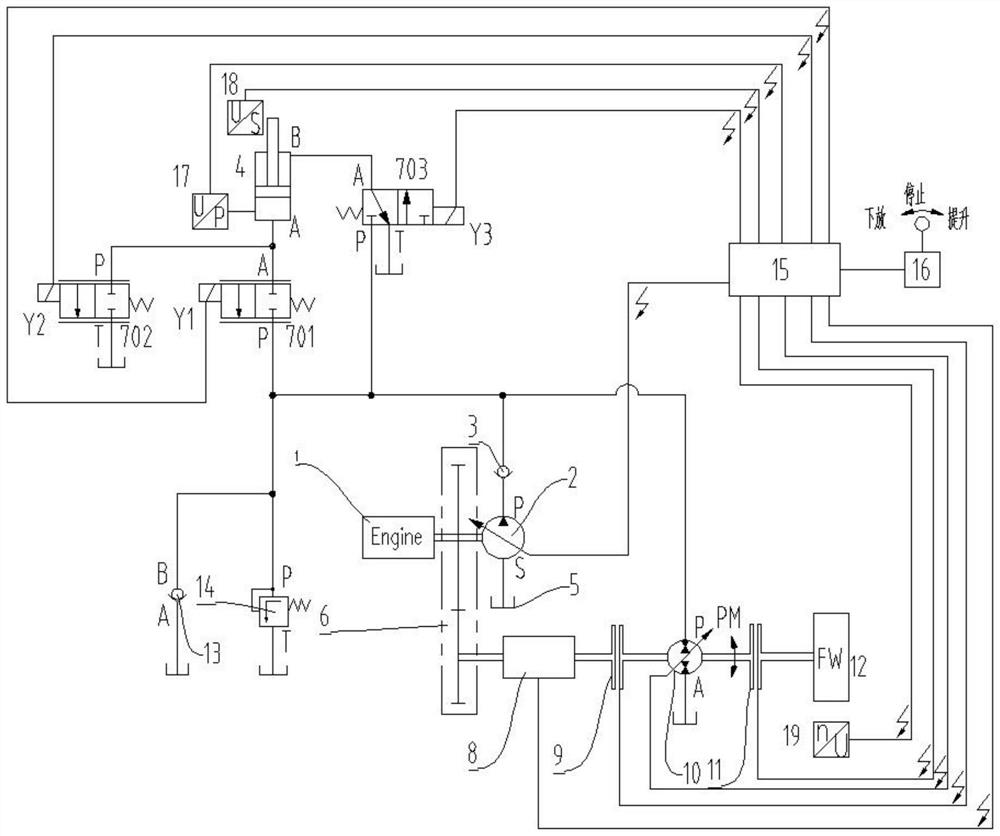

[0033] Such as figure 2 and Figure 4 As shown, a flywheel-based hybrid mechanical system for an excavator includes a prime mover 1, a hydraulic pump 2, a boom hydraulic cylinder 4, a second reversing valve 702, a rotational speed sensor 19, a pressure sensor 17 and a control The prime mover 1 is connected to the hydraulic pump 2 through the transfer case 6 to provide power for the hydraulic pump 2, and the oil suction port S of the hydraulic pump 2 is connected to the fuel tank 5; the prime mover 1 is generally a diesel engine or other engine, and can also be an electric motor, etc. .

[0034] The oil outlet P of the hydraulic pump 2 is respectively connected with the P port of the first reversing valve 701, the P port of the third reversing valve 703 and the P port of the hydraulic pump / motor 10 through the check valve 3; the P port of the hydraulic pump 2 The port is also connected to the P port of the main relief valve 14 through the check valve 3, and the T port of the...

Embodiment 2

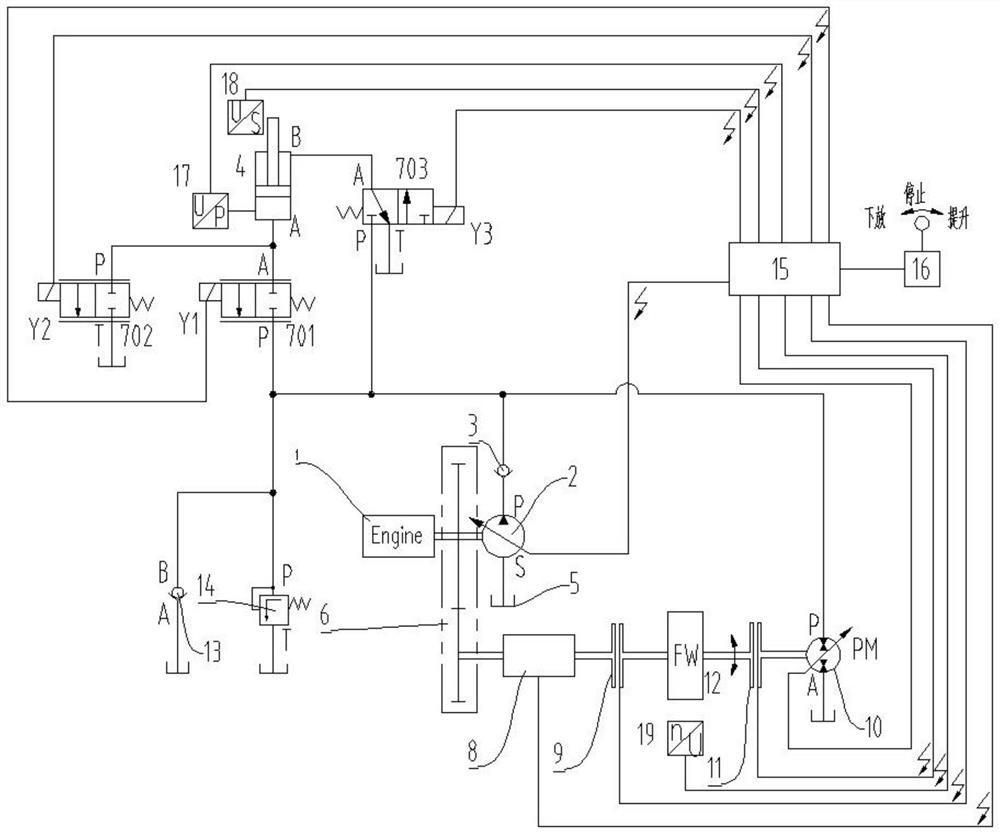

[0043] Such as image 3 and Figure 4 As shown, a flywheel-based hybrid mechanical system for an excavator includes a prime mover 1, a hydraulic pump 2, a boom hydraulic cylinder 4, a second reversing valve 702, a rotational speed sensor 19, a pressure sensor 17 and a control The prime mover 1 is connected to the hydraulic pump 2 through the transfer case 6 to provide power for the hydraulic pump 2, and the oil suction port S of the hydraulic pump 2 is connected to the fuel tank 5; the prime mover 1 is generally a diesel engine or other engine, and can also be an electric motor, etc. .

[0044] The oil outlet P of the hydraulic pump 2 is respectively connected with the P port of the first reversing valve 701, the P port of the third reversing valve 703 and the P port of the hydraulic pump / motor 10 through the check valve 3; the P port of the hydraulic pump 2 The port is also connected to the P port of the main relief valve 14 through the check valve 3, and the T port of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com