Diesel engine hood and manufacturing technique thereof

An engine cover and engine technology, applied in the direction of machines/engines, manufacturing tools, engine components, etc., can solve the problems of weak heat dissipation capacity of the engine block and poor user experience of the engine block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

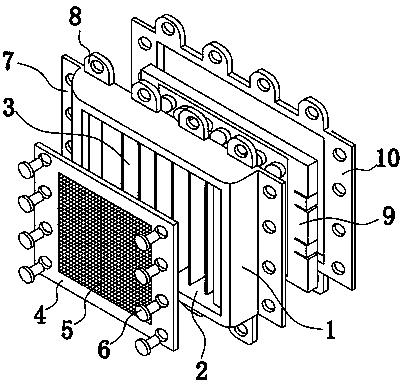

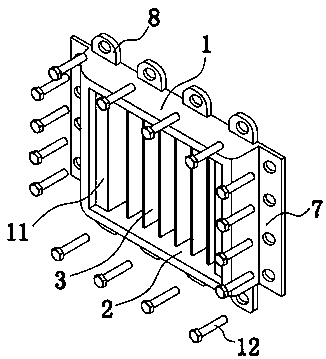

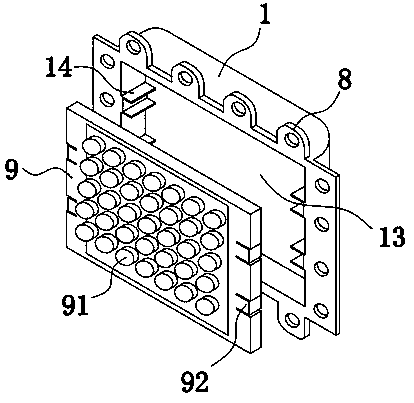

[0028] The present invention provides such Figure 1-3 A diesel engine cover body, including an engine cover body 1, the top of the engine cover body 1 is provided with a top groove 2, and the top groove 2 is provided with a heat sink integrated with the engine cover body 1. Metal sheets 3, the heat dissipation metal sheets 3 are equidistantly arranged, the left and right inner sides of the top groove 2 are provided with support protrusions 11 for installing the dust-proof board 4, and the middle part of the dust-proof board 4 is provided with Air vent 5, the lower end of the engine cover body 1 is provided with a bottom groove 13, the bottom groove 13 is provided with a sound insulation board 9, and the surface of the sound insulation board 9 is provided with a noise reduction protrusion 91.

[0029] Specifically, the upper and lower rear ends of the engine cover body 1 are provided with mounting ears 8 , which are integrated with the engine cover body 1 , and the mounting ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com