Tile holder for combustor of gas turbine

A gas turbine and retainer technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of difficult positioning and dangerous mechanical resistance, and achieve the effect of improving the ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

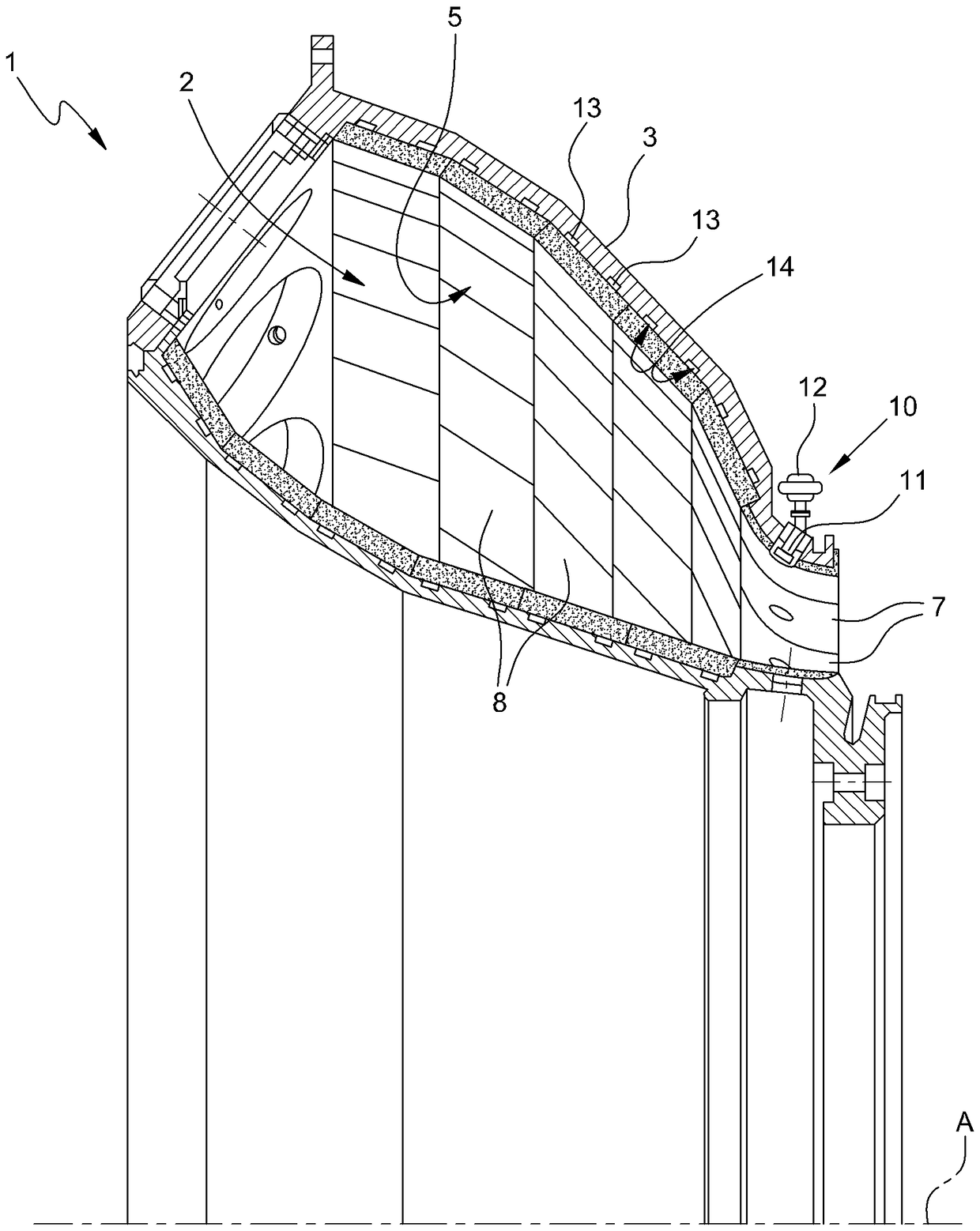

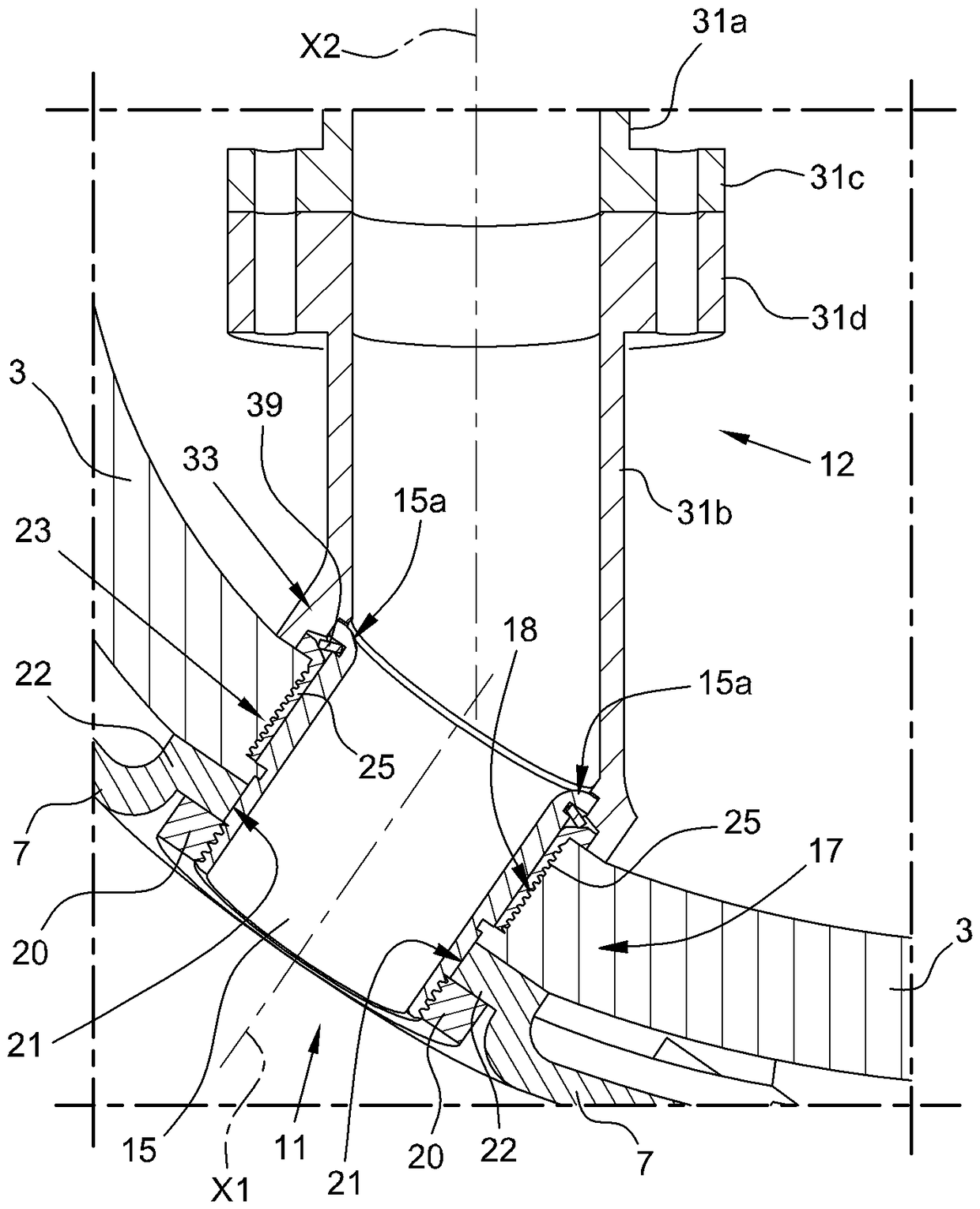

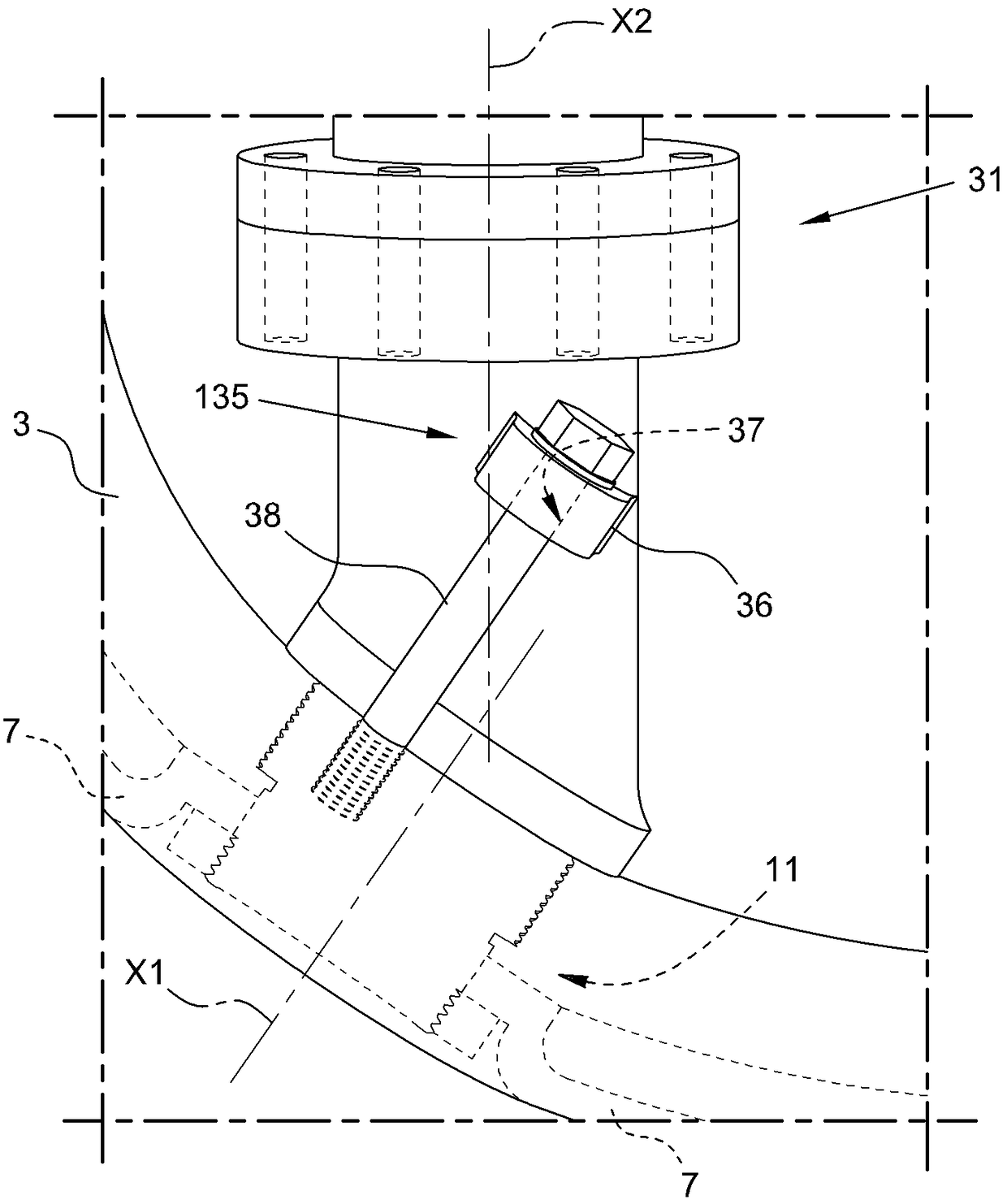

[0046] figure 1 A combustor 1 of a gas turbine is shown (with some parts removed for clarity). The burner 1 comprises an annular combustion chamber 2 extending around an axis A and having an envelope delimited by an annular wall 3 and a heat shield 5 on the inner surface of the annular wall 3 . However, the arrangements described herein are given by way of example only and are not to be considered limiting. In particular, the combustor may be of any type such as a bin or barrel or tube type.

[0047] The heat shield 5 comprises a plurality of first insulating tiles 7 of metal alloy and a plurality of second insulating tiles 8 of refractory material, all arranged in adjacent circumferential rows around the axis A of the combustion chamber 2 . In one embodiment, the insulating tiles 7, 8 may be substantially quadrilateral. However, other shapes are also available.

[0048] At least one of the first insulating shoes 7 selected for the purpose of coupling the silencer is fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com