Method for electromagnetically nondestructively detecting metal surface cracks by multi-frequency exciting field array

A non-destructive testing, metal surface technology, applied in the direction of material magnetic variables, etc., can solve the problems of detection of random distribution of crack defects without mentioning sensitivity, single amplitude and frequency excitation source, etc., to achieve effective detection and identification, strong use value, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

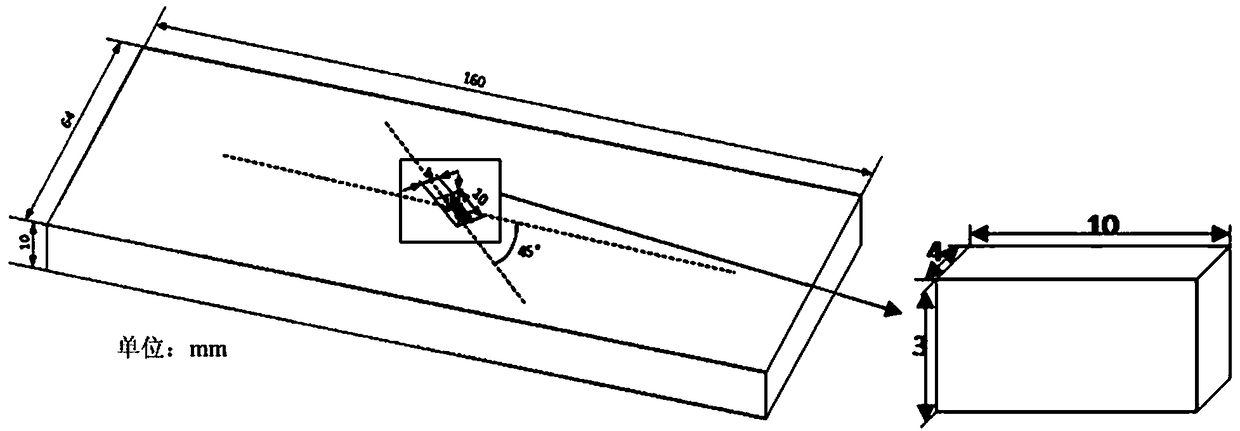

[0036] In this embodiment, the test piece is made of commonly used low-carbon steel Q235 steel, with a length of 160 mm, a width of 64 mm, and a thickness of 10 mm.

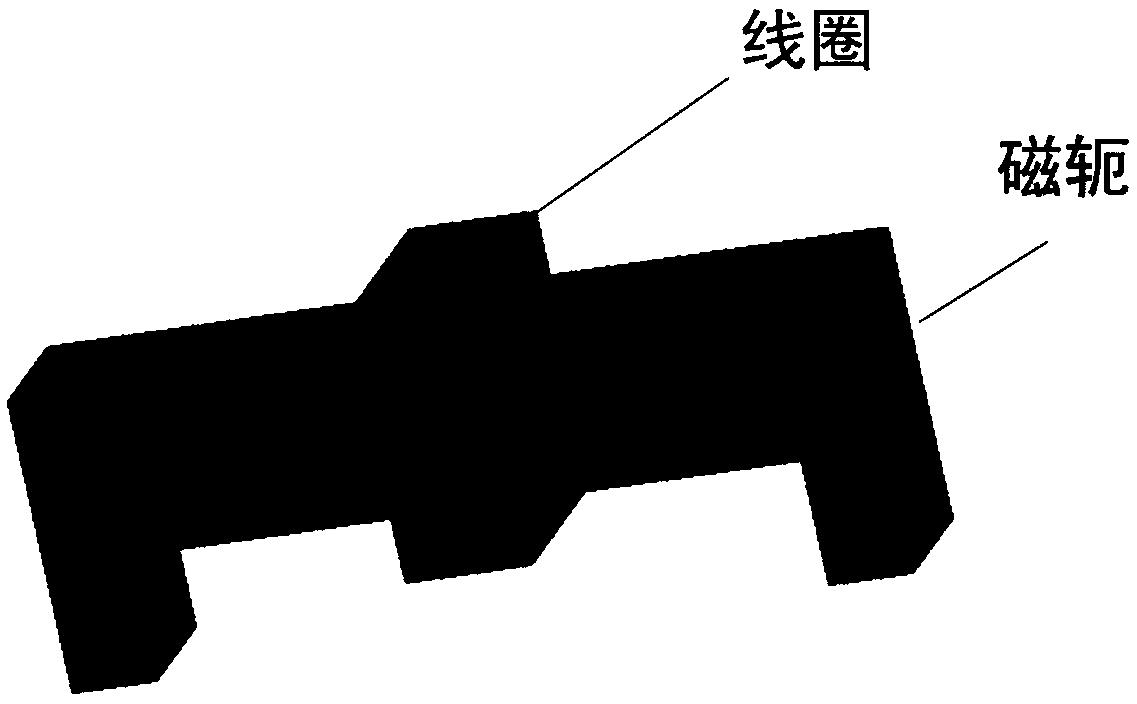

[0037] In this embodiment, the excitation device such asfigure 1 As shown, it consists of a U-shaped yoke and a square excitation coil wound in the middle. The excitation coil is made of enameled wire with a wire diameter of 0.6mm. The inner length of the coil is 20mm, and the outer length of the coil is 32mm. The effective length The U-shaped yoke is made of No. 10 steel, and its relative magnetic permeability is 10000. The outer size is 100mm*20mm*35mm, and the inner size is 80mm*20mm*15mm.

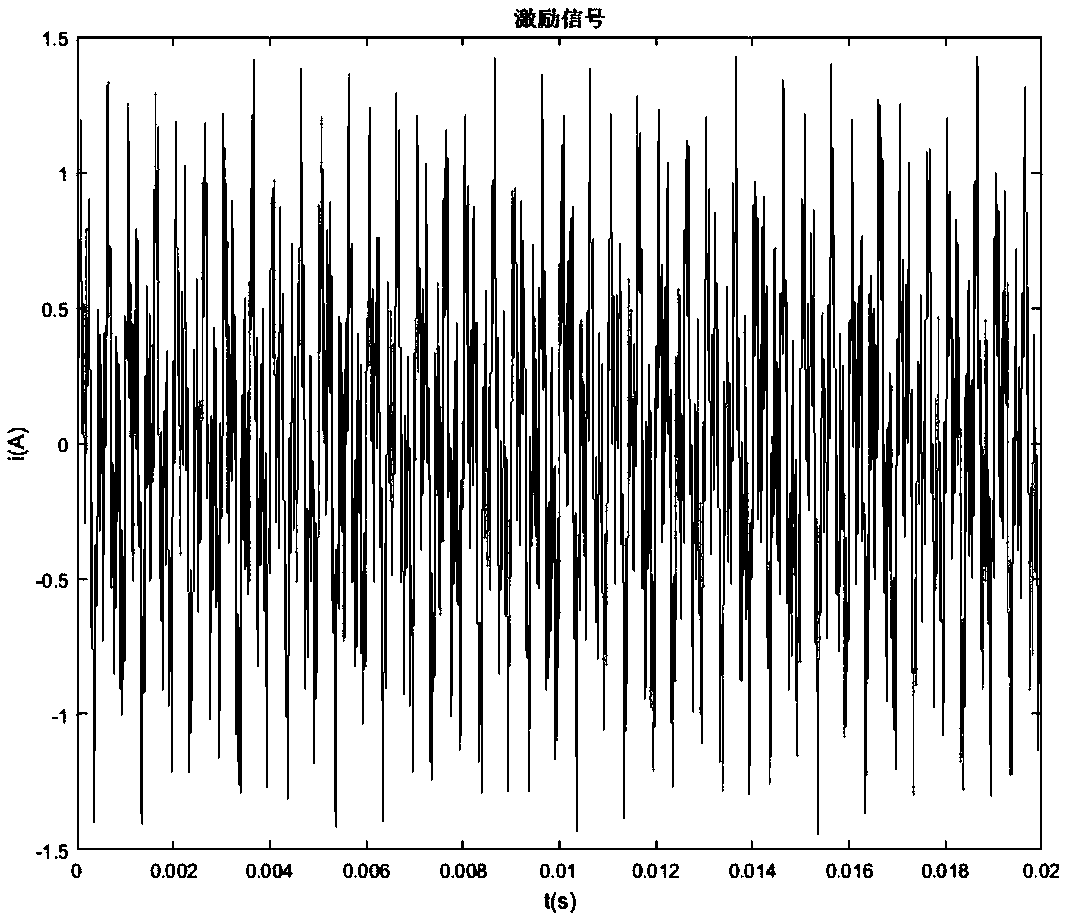

[0038] In this embodiment, the excitation signal in the excitation coil is as figure 2 As shown, it is formed by superposition of 2kHz, 5kHz and 10kHz sinusoidal currents whose amplitudes are all 0.5a, and the excitation period of the multi-frequency signal is 0.5ms.

[0039] A multi-frequency excitation field array elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com