Electromagnetic coil magnetic drive operation method, magnetic drive mechanism and impact device

A magnetic drive and electromagnetic coil technology, applied in electromagnets, electromagnets with armatures, circuits, etc., can solve problems such as inability to pass through the whole process, limited movement of magnetic induction bodies, and restrictions on the application range and fields of electromagnetic products, and achieve Small wear, direct energy conversion, ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

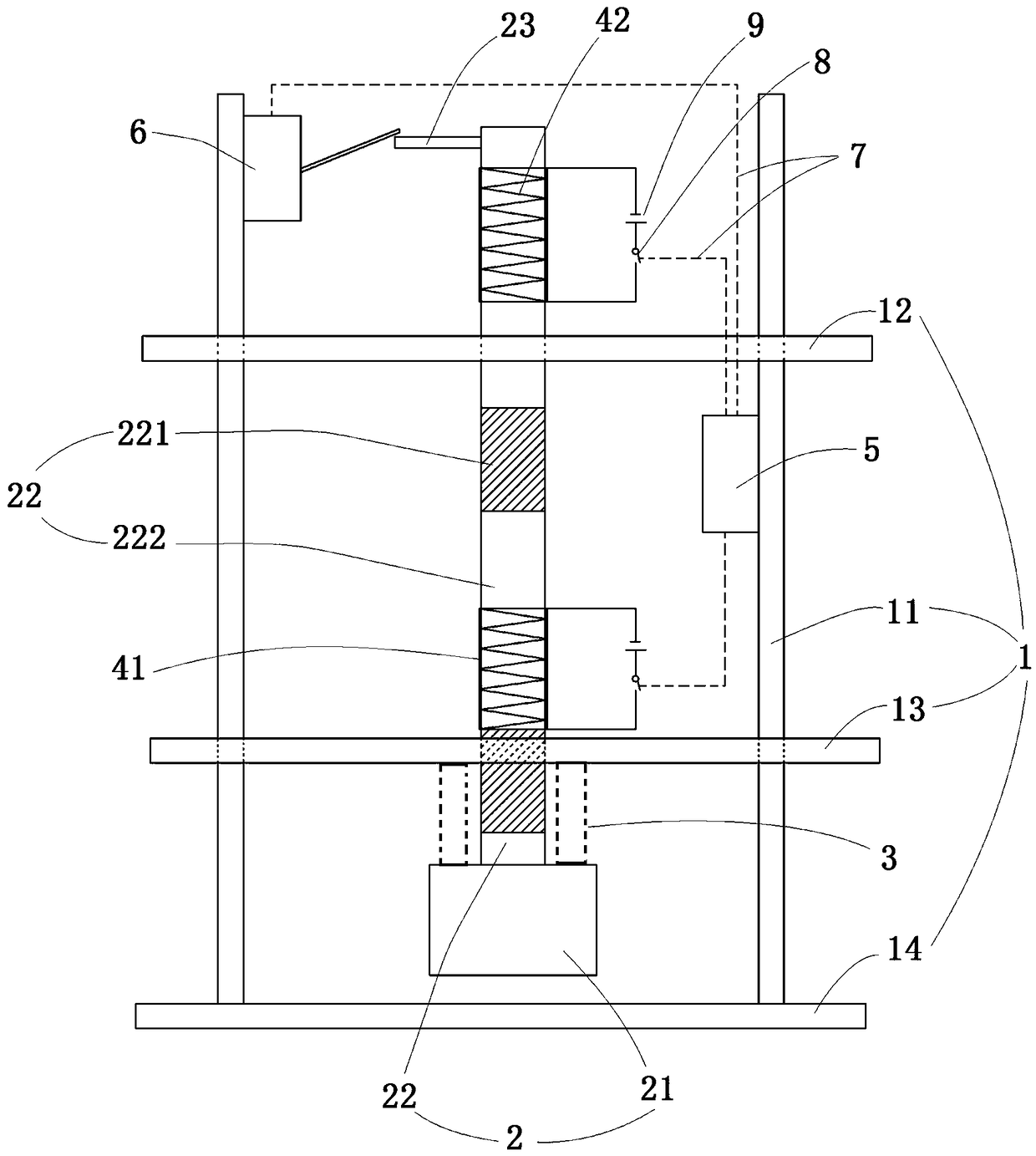

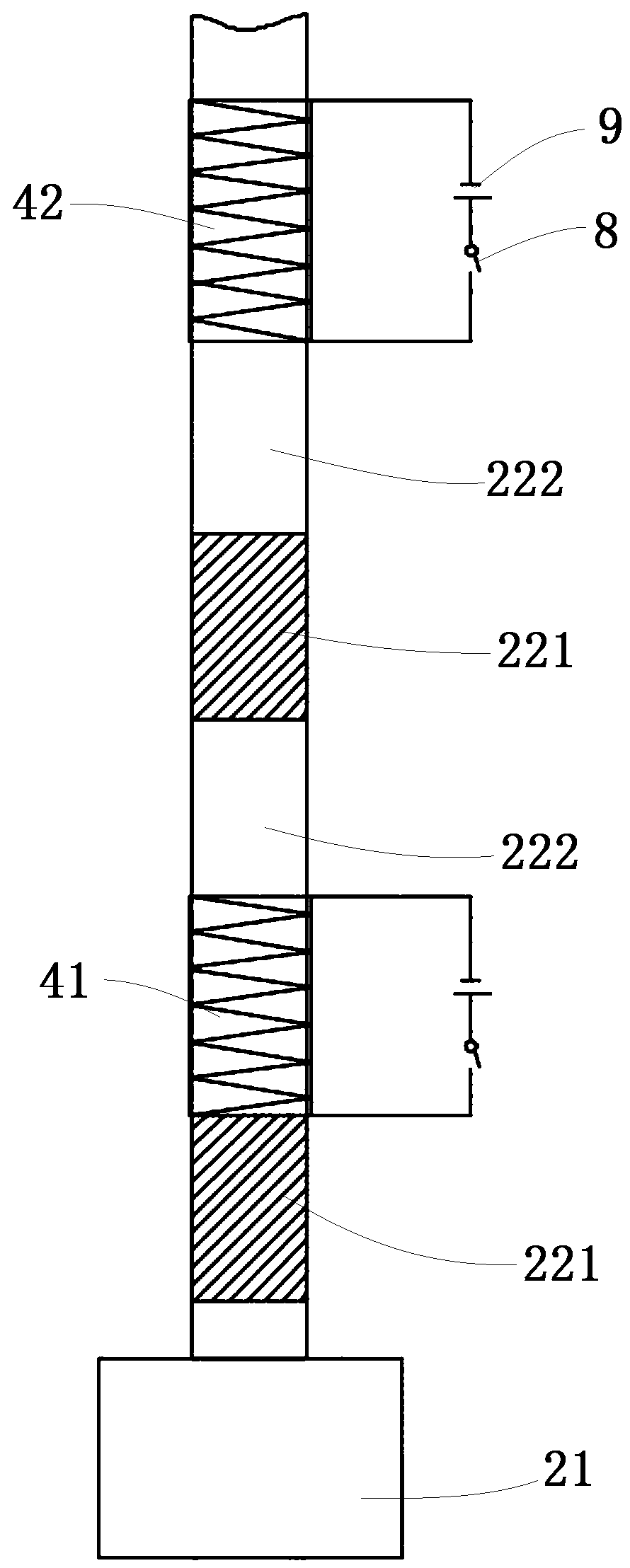

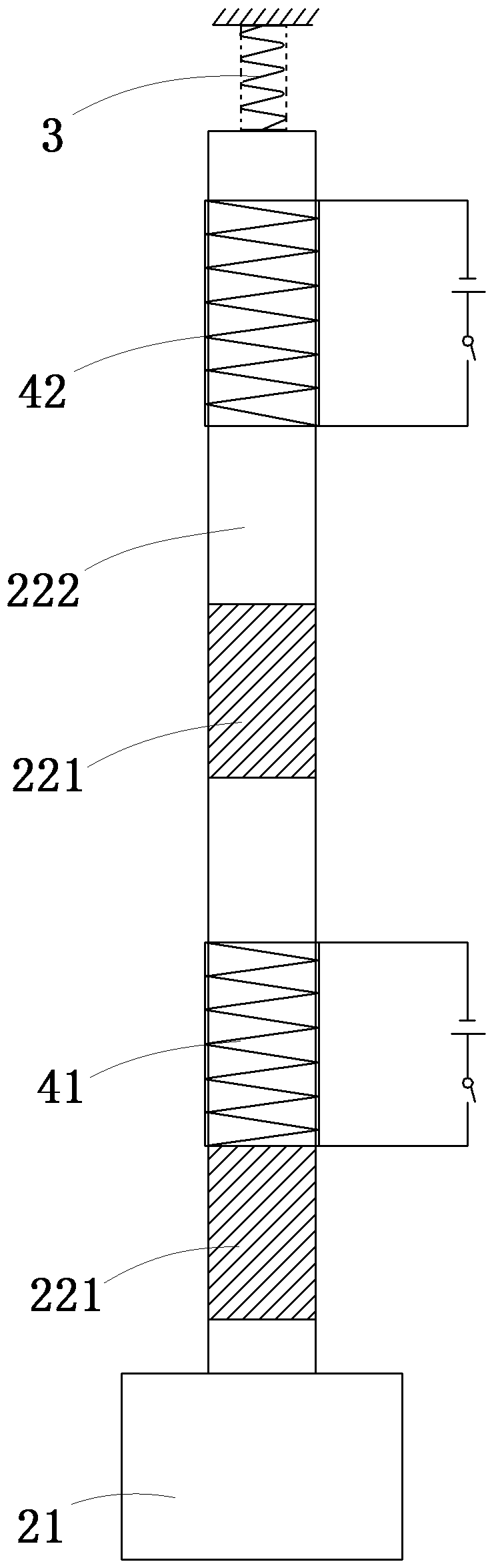

Embodiment 1

[0041] Embodiment 1 of the electromagnetic coil magnetic driving operation method of the present invention: This embodiment is described for a coil, that is, the number of coils m=1, and the magnetic induction body is a moving body, and the coil is a fixed body. A magnetic induction body is arranged on one side of the axial direction of the coil, and the magnetic induction body is arranged in the magnetic induction area formed by one end of the coil after the coil is energized so that the coil can be attracted after the coil is energized, and then the coil is energized by the controller, and the coil The generated magnetic field attracts the magnetic sensor, so that the magnetic sensor moves along the axis of the coil to the direction close to the coil. When the magnetic sensor moves to the middle position of the magnetic core of the coil magnetic field, the control coil is powered off, and the magnetic sensor The body continues to move forward under the action of inertia, so t...

Embodiment 2

[0042] Embodiment 2 of the electromagnetic coil magnetic driving operation method of the present invention: This embodiment is described for the scheme of more than two coils, that is, the number of coils m≥2, and the magnetic induction body is a moving body, and the coil is a fixed body. Set two or more coils in sequence along the set straight line, the number of coils is selected according to the needs of use, the axis of the coil is collinear with the set straight line, and the magnetic induction body is arranged on the front side of the first coil axis direction and the magnetic induction body Located in the magnetic induction area formed by the front end of the first coil after it is energized, the controller controls the first coil to be energized, and the magnetic induction body moves toward the first coil along the axis of the coil, and then adopts the following control steps: When the magnetic induction When the magnetic core of the body moves to the center of the magn...

Embodiment 3

[0043] Embodiment 3 of the electromagnetic coil magnetic driving operation method of the present invention: This embodiment is described for a coil, that is, the number of coils n=1, and the magnetic induction body is a moving body, and the coil is a fixed body. A magnetic induction body is arranged on one side of the coil axis direction, and limit pieces are respectively provided at the front and rear limit positions of the magnetic induction body to limit the range of motion of the magnetic induction body between the two limit pieces; There are also front and rear initial positions in the moving stroke that are respectively located in the magnetic induction area formed by the front and rear ends of the coil when it is energized. The following control steps are adopted: when the magnetic induction body is located at the front initial position, the coil is controlled by the controller. When energized, the magnetic sensor moves toward the coil along the axis of the coil. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com