A trimethylamine functionalized polyarylindole anion exchange membrane and a preparation method thereof

An ion exchange membrane, functionalized technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

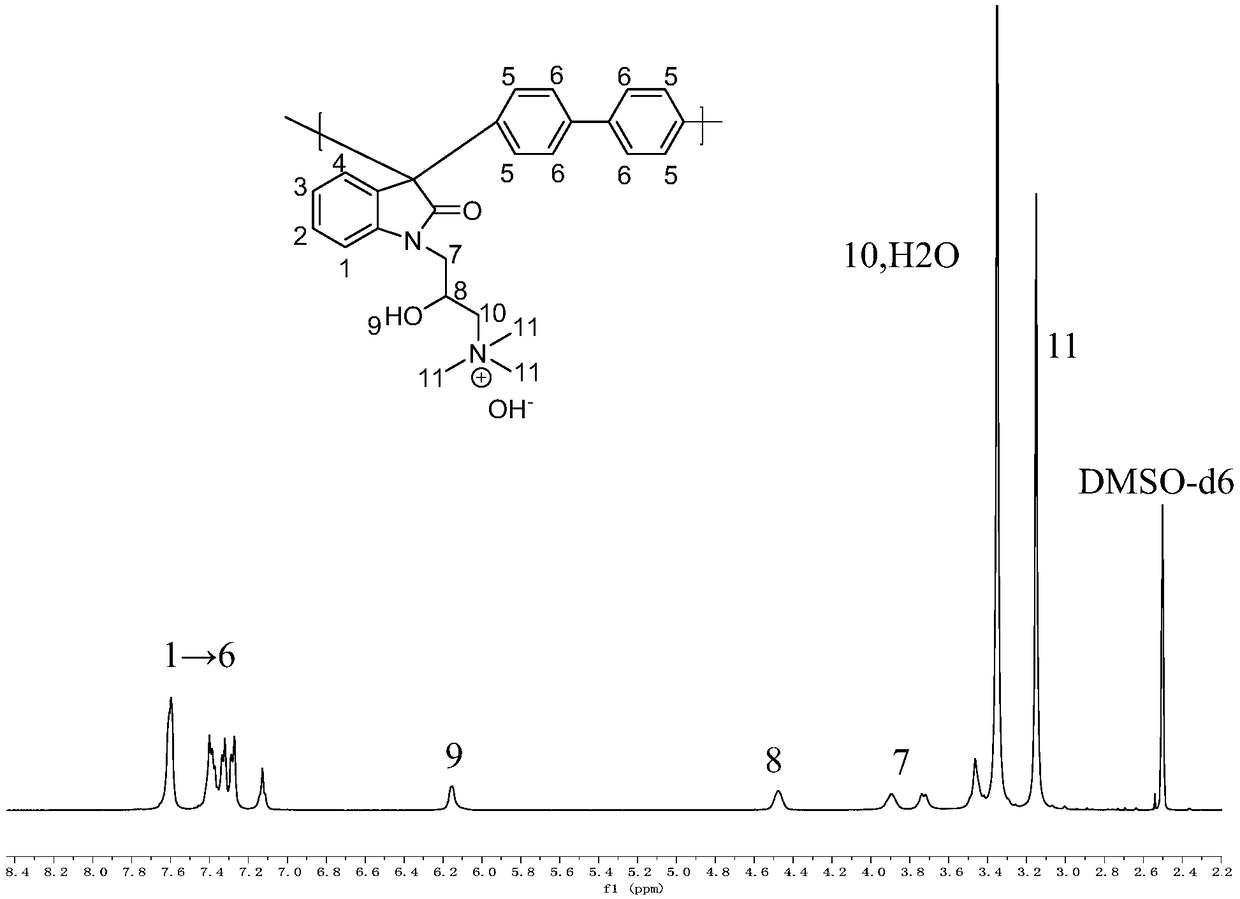

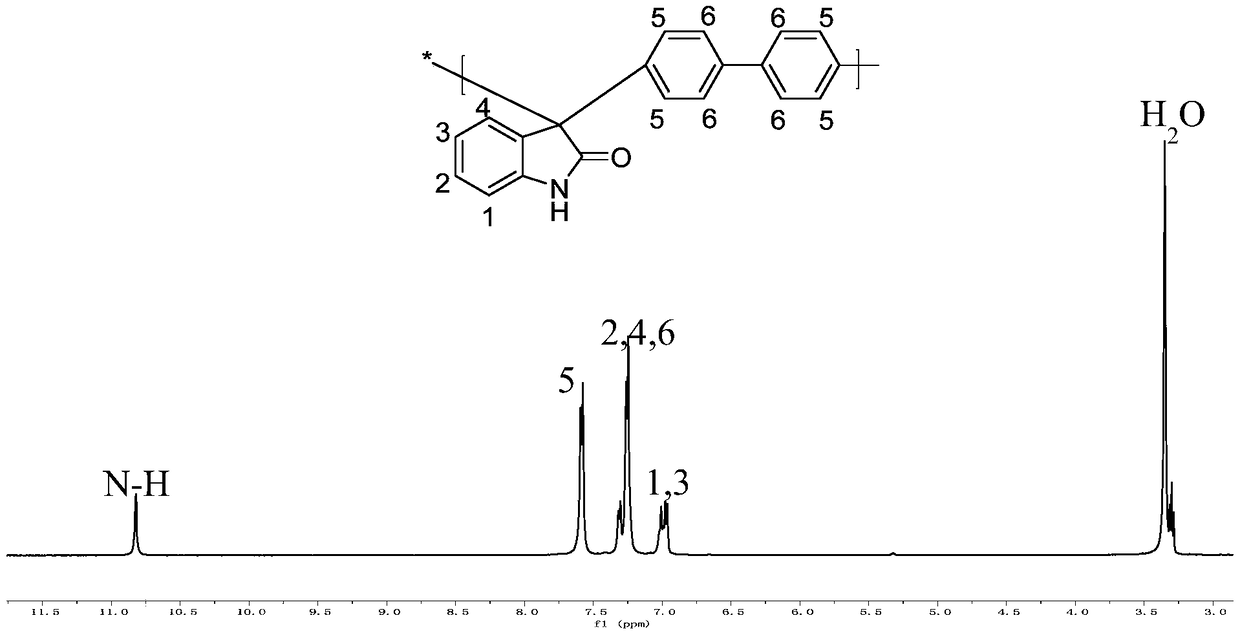

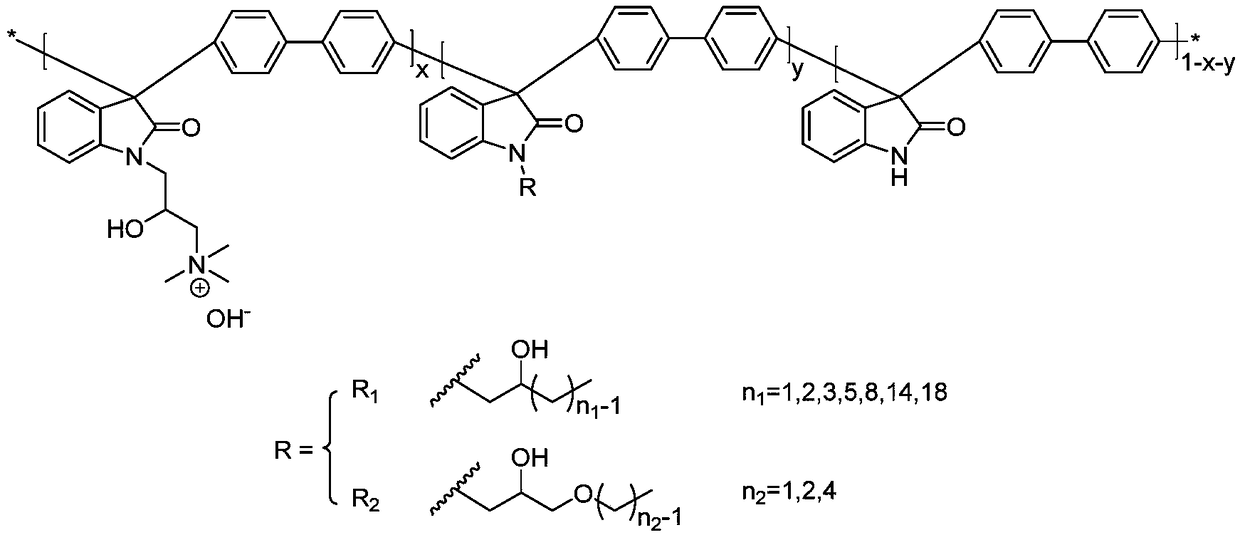

Method used

Image

Examples

Embodiment 1

[0045] Synthesis of polyarylindole polymer: under the protection of inert gas, 5.25g 2,3-indoledione and 5.42g biphenyl were dissolved in 6mL methylene chloride and 11mL trifluoroacetic acid, after completely dissolving, the The reaction was placed in an ice-bath environment, 25 mL of trifluoromethanesulfonic acid was slowly added, and then the temperature was gradually raised to room temperature for about 0.5 to 2 hours. When the reaction turned into a highly viscous liquid, the reaction ended, and it was poured into methanol to obtain a blocky white solid, soaked for about 12 hours, filtered and dried to obtain a crude product. Dissolve the crude product in about 120mL of NMP, pour it into methanol after completely dissolving to obtain a white fibrous solid, soak for 24 hours, filter, wash with methanol for more than three times, and dry at 60°C for 24 hours in a vacuum environment to obtain the purified polyarylene Indole polymers.

[0046] Preparation of trimethylamine-fu...

Embodiment 2

[0051]Synthesis of polyarylindole polymer: under the protection of inert gas, 5.25g 2,3-indoledione and 5.42g biphenyl were dissolved in 6mL methylene chloride and 11mL trifluoroacetic acid, after completely dissolving, the The reaction was placed in an ice-bath environment, 25 mL of trifluoromethanesulfonic acid was slowly added, and then the temperature was gradually raised to room temperature for about 0.5 to 2 hours. When the reaction turned into a highly viscous liquid, the reaction ended, and it was poured into methanol to obtain a blocky white solid, soaked for about 12 hours, filtered and dried to obtain a crude product. Dissolve the crude product in about 120mL of NMP, pour it into methanol after completely dissolving to obtain a white fibrous solid, soak for 24 hours, filter, wash with methanol for more than three times, and dry at 60°C for 24 hours in a vacuum environment to obtain the purified polyarylene Indole polymers.

[0052] Preparation of trimethylamine-fun...

Embodiment 3

[0057] Synthesis of polyarylindole polymer: under the protection of inert gas, 5.25g 2,3-indoledione and 5.42g biphenyl were dissolved in 6mL methylene chloride and 11mL trifluoroacetic acid, after completely dissolving, the The reaction was placed in an ice-bath environment, 25 mL of trifluoromethanesulfonic acid was slowly added, and then the temperature was gradually raised to room temperature for about 0.5 to 2 hours. When the reaction turned into a highly viscous liquid, the reaction ended, and it was poured into methanol to obtain a blocky white solid, soaked for about 12 hours, filtered and dried to obtain a crude product. Dissolve the crude product in about 120mL of NMP, pour it into methanol after completely dissolving to obtain a white fibrous solid, soak for 24 hours, filter, wash with methanol for more than three times, and dry at 60°C for 24 hours in a vacuum environment to obtain the purified polyarylene Indole polymers.

[0058] Preparation of trimethylamine-fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com