Grounding device connector for mechanized construction based on whole process

A grounding device, the whole process technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems affecting the realization of mechanized construction, and achieve the effect of simple structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

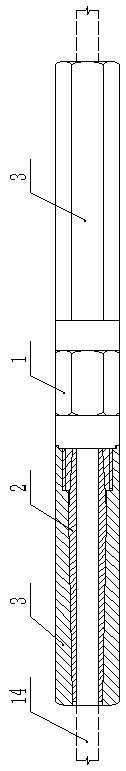

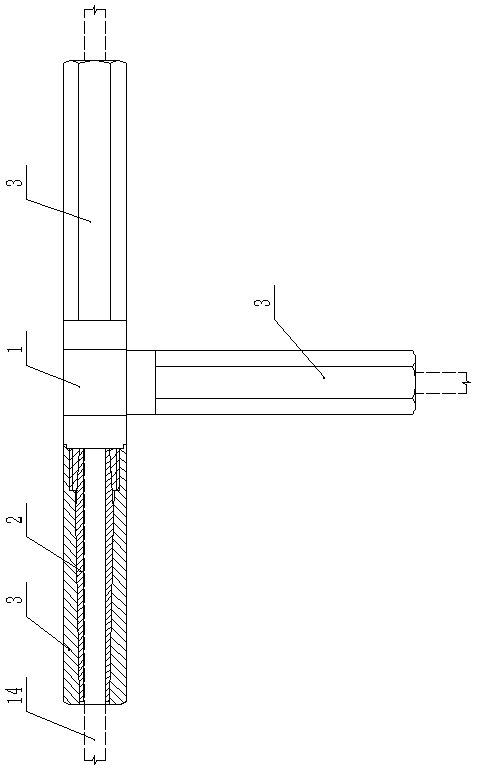

[0033] Such as figure 1 , figure 2 , Figure 9-Figure 12 As shown, the present invention is based on the grounding device connector for the whole process of mechanized construction, including: connecting block 1, connecting inner pipe 2 and connecting outer pipe 3;

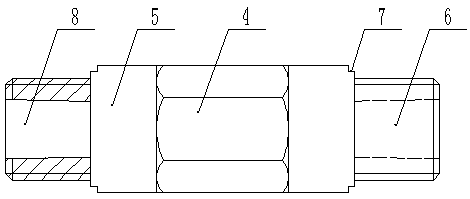

[0034] The structure of the connecting block 1 is that two cylindrical steps 5 are radially fixed on the connecting block body 4, and a threaded part 6 is coaxially fixed on each step part 5, and the threaded part 6 is fixed on the step part 5. One end connected to the part 6 is provided with an inwardly contracting step 7, and the threaded part 6 is provided with an external thread, and a tapered blind hole 8 with a large outside and a small inside is opened in the axial direction;

[0035] The connecting inner tube 2 is a double-ended conical shape with thin ends and a thick middle, and a circular through hole 9 is opened in the axial direction, and a plurality of axial contraction joints 10 are opened on the...

Embodiment 2

[0043] Such as image 3 , Figure 4 , Figure 9-Figure 12 As shown, the present invention is based on the grounding device connector for the whole process of mechanized construction. The number of outer tubes 3 is also three.

Embodiment 3

[0045] Such as Figure 5 , Image 6 , Figure 9-Figure 12 As shown, the present invention is based on the grounding device connector used in the whole process of mechanized construction. The number of outer tubes 3 is also four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com