A method of making titanium mesh for alveolar bone defect

A production method and technology of alveolar bone, applied in the direction of skull, bone implants, medical science, etc., can solve the problems of lack of titanium mesh auxiliary tools with precise positioning ability, poor surgical effect, wound dehiscence, etc., and achieve reduction The difficulty of surgery and the probability of postoperative complications, the effect of improving surgical accuracy and treatment effect, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

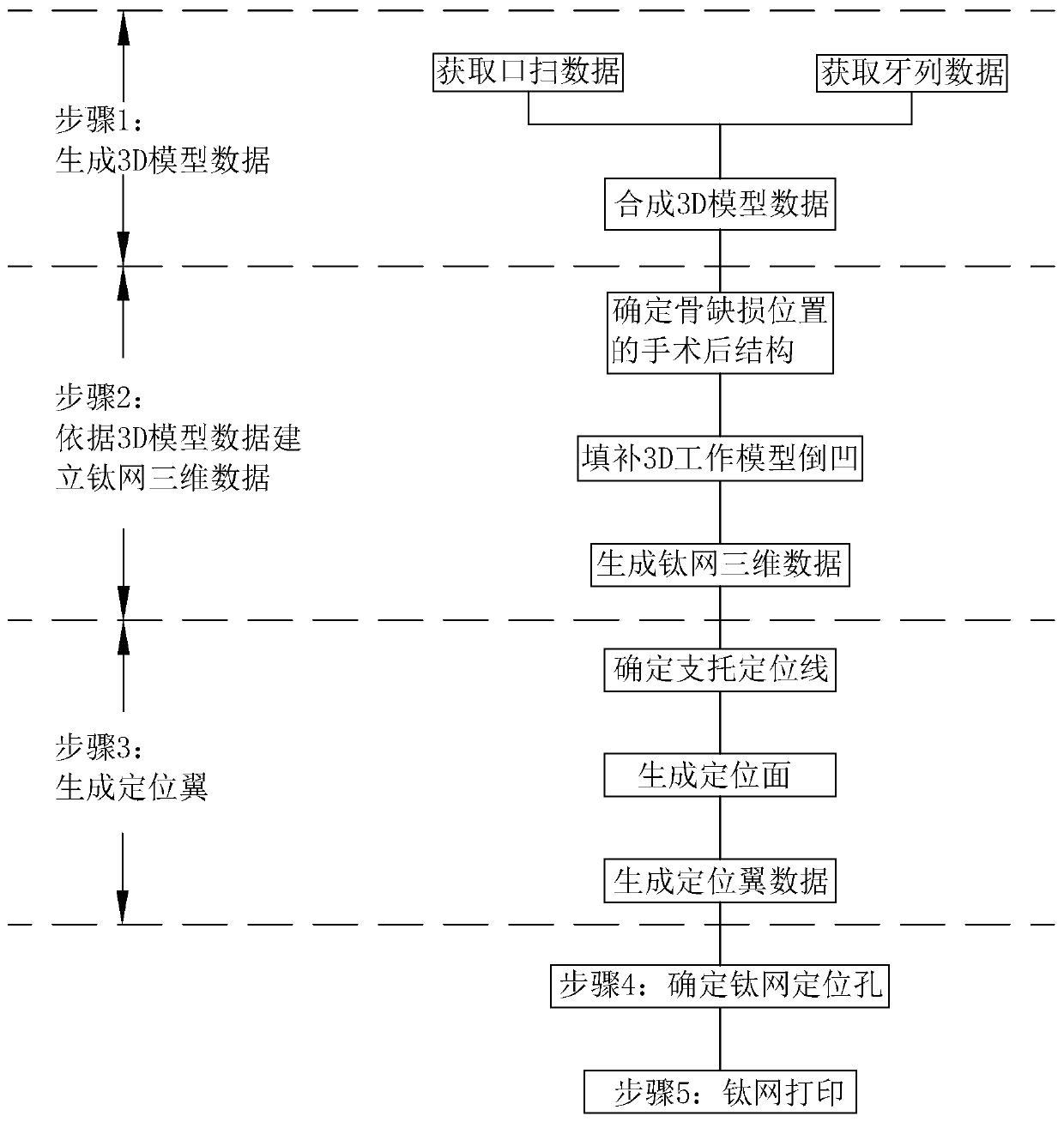

[0042] A method for making titanium mesh for alveolar bone defect, such as figure 1 and figure 2 shown, including the following steps:

[0043] Step 1: Generate 3D model data.

[0044] Step 1-1: Obtain the oral scan data, and scan the oral cavity through the oral scanner to obtain the oral scan data with clear dentition.

[0045] Step 1-2: Obtain dentition data, and scan the oral cavity through CBCT technology to obtain CT data with clear jaw structure.

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com