Formaldehyde removing agent and preparation method thereof

A formaldehyde scavenger and stabilizer technology, applied in the field of formaldehyde scavenger and its preparation, can solve the problems of insignificant scavenging effect, low scavenging efficiency, environmental pollution, etc., achieve excellent thermodynamic stability, prevent moisture from entering, and solve the problem of moisture. The effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides the preparation method of the formaldehyde scavenger of an embodiment, comprises steps:

[0035] Prepare the aqueous solution containing soybean extract, the aqueous solution containing cocoa extract, the aqueous solution containing green tea extract and the aqueous solution containing camphor leaf extract of specified content respectively;

[0036] The above-mentioned aqueous solution containing soybean extract, aqueous solution containing cocoa extract, aqueous solution containing green tea extract and aqueous solution containing camphor leaf extract are mixed in a specified order to prepare a plant extract mixture, and the above plant extract mixture is placed in the Stirring continues for a first specified time at a specified temperature;

[0037] adding the buffering agent to the above plant extract mixture and stirring at a specified temperature for a second specified time to form a mixed system;

[0038] Add accelerator, stabi...

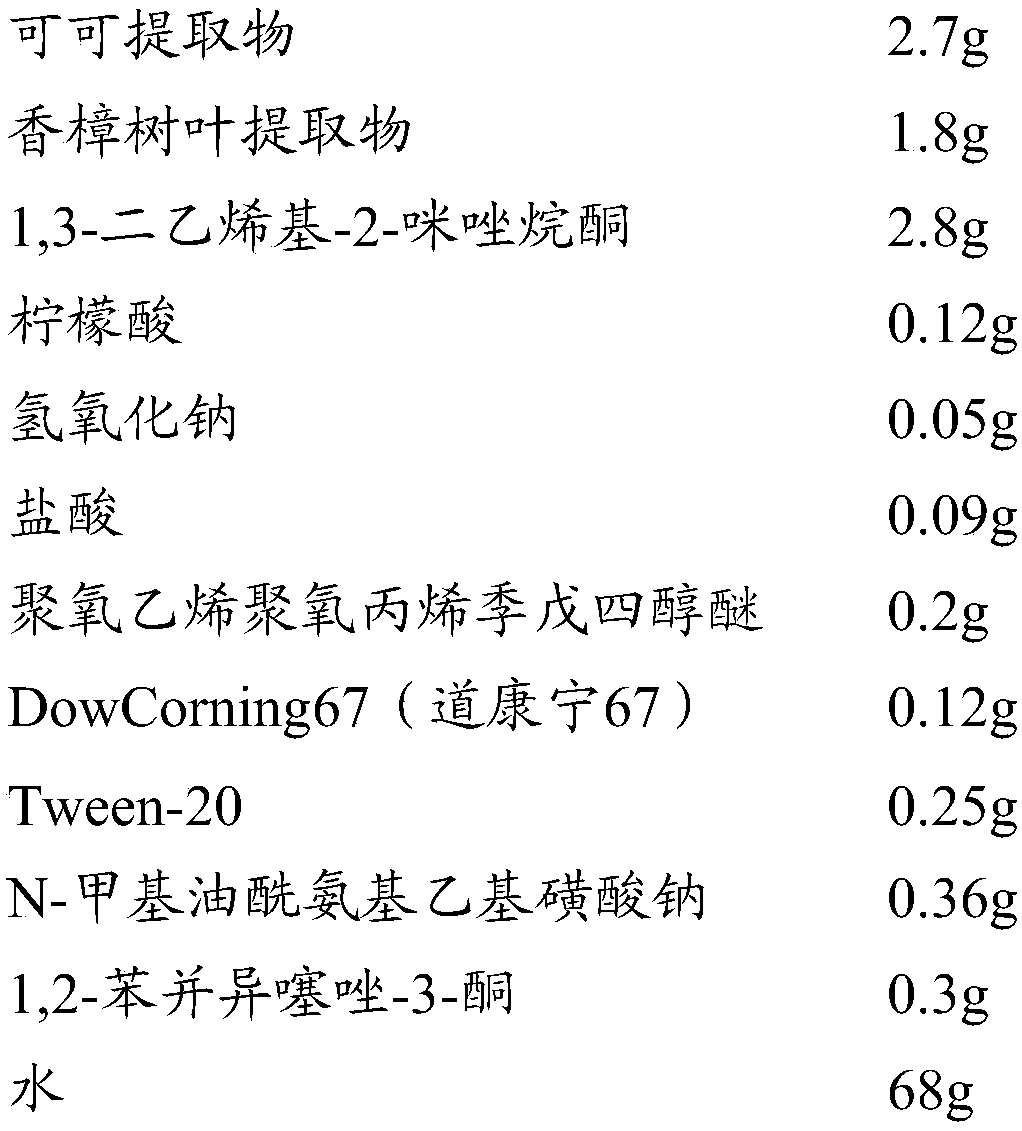

specific Embodiment 1

[0043] The raw material of the formaldehyde scavenger that specific embodiment 1 of the present invention provides comprises:

[0044]

[0045]

[0046] Measure each of the above groups separately, use 4 containers to hold 17g of water respectively and label the containers as a1, b1, c1 and d1, then add soybean extract, green tea extract, cocoa extract and camphor leaf extract respectively Add to a1, b1, c1 and d1 to make soybean extract-containing aqueous solution, cocoa extract-containing aqueous solution, green tea extract-containing aqueous solution and camphor tree leaf extract-containing aqueous solution; feed in small centrifugal pump The aqueous solution containing soybean extract and the aqueous solution containing cocoa extract are respectively fed into the mouth, and the aqueous solution containing green tea extract and the aqueous solution containing camphor leaf extract are mixed with a box-type water pump, and the two are used as a cycle to generate negative...

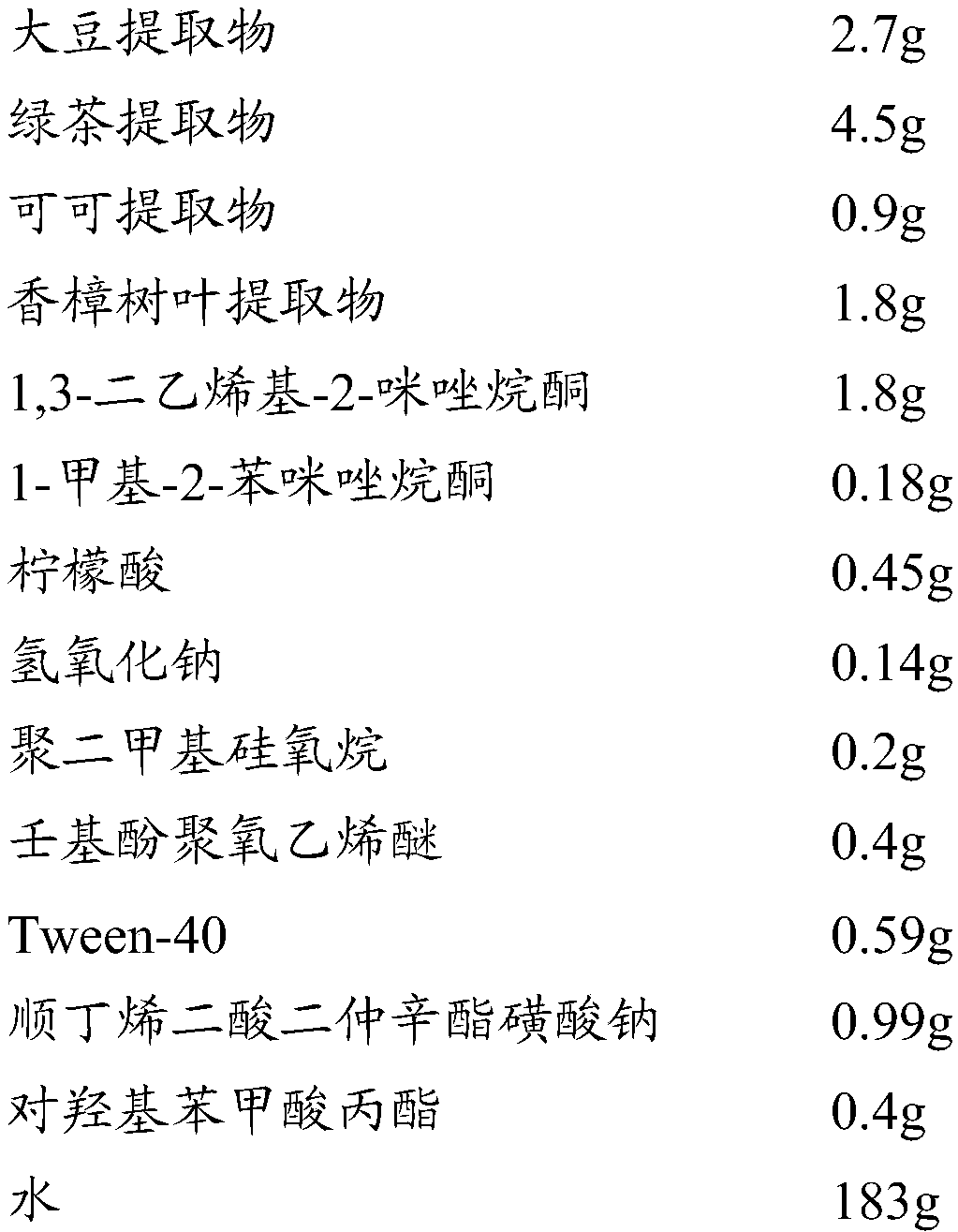

specific Embodiment 2

[0047] The raw material of the formaldehyde scavenger that specific embodiment 2 of the present invention provides comprises:

[0048]

[0049] The above groups are measured separately, and 4 containers are used to hold 45.75g of water respectively, and the containers are labeled as a2, b2, c2 and d2, and then the soybean extract, green tea extract, cocoa extract and camphor leaf extract are respectively Add dropwise to a2, b2, c2 and d2 to make an aqueous solution containing soybean extract, an aqueous solution containing cocoa extract, an aqueous solution containing green tea extract and an aqueous solution containing camphor leaf extract; The feed port enters the aqueous solution containing soybean extract and the aqueous solution containing cocoa extract respectively, and uses a box-type water flushing pump to mix the aqueous solution containing green tea extract and the aqueous solution containing camphor leaf extract and use the two as a cycle to generate negative pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com