Welding technology for improving pipe and end socket connected J-shaped groove welding line quality

A groove welding seam and welding process technology, which is applied in the field of welding technology of J-shaped groove welding seam quality, can solve the problems of large residual stress of the welding seam, no heat treatment, complex structure, etc., so as to control welding deformation and reduce restraint. degree, the effect of preventing thermal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

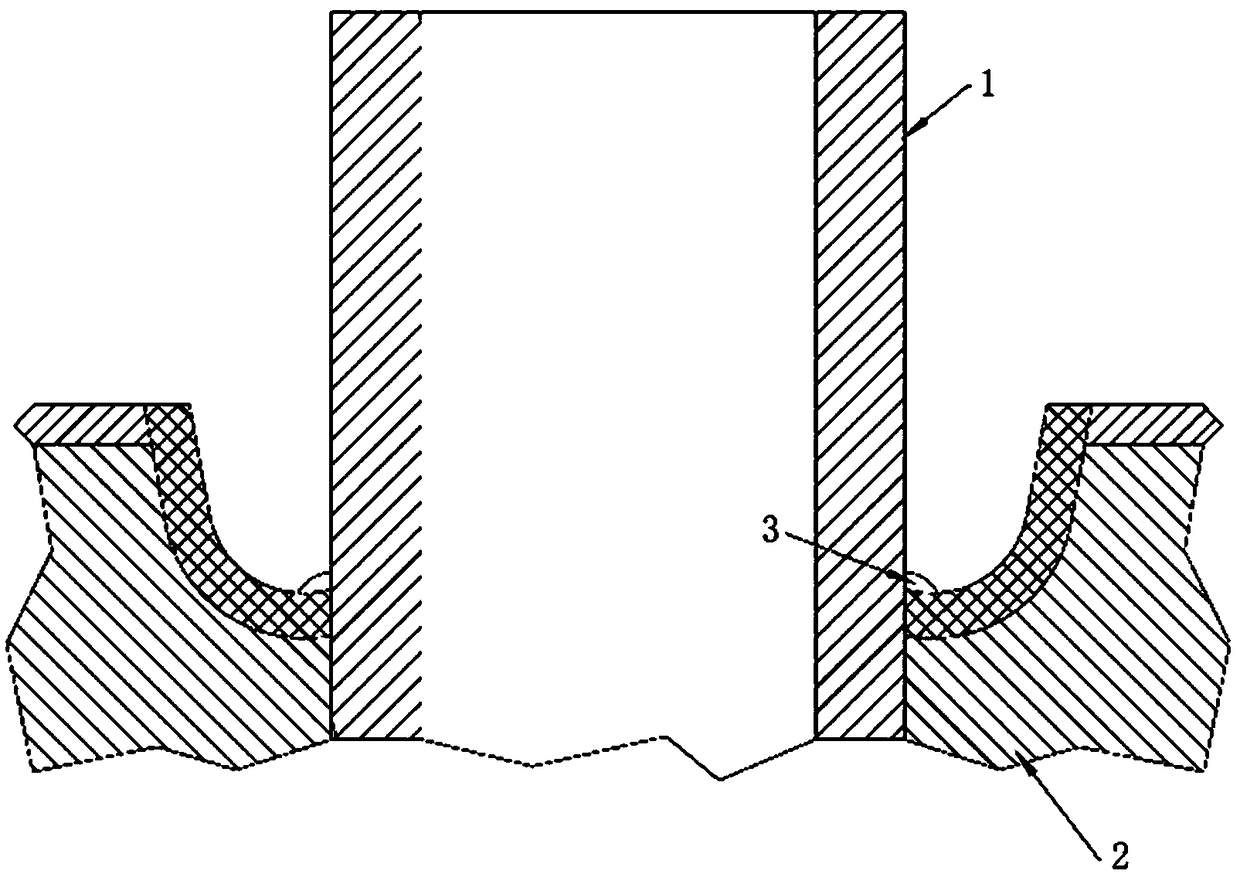

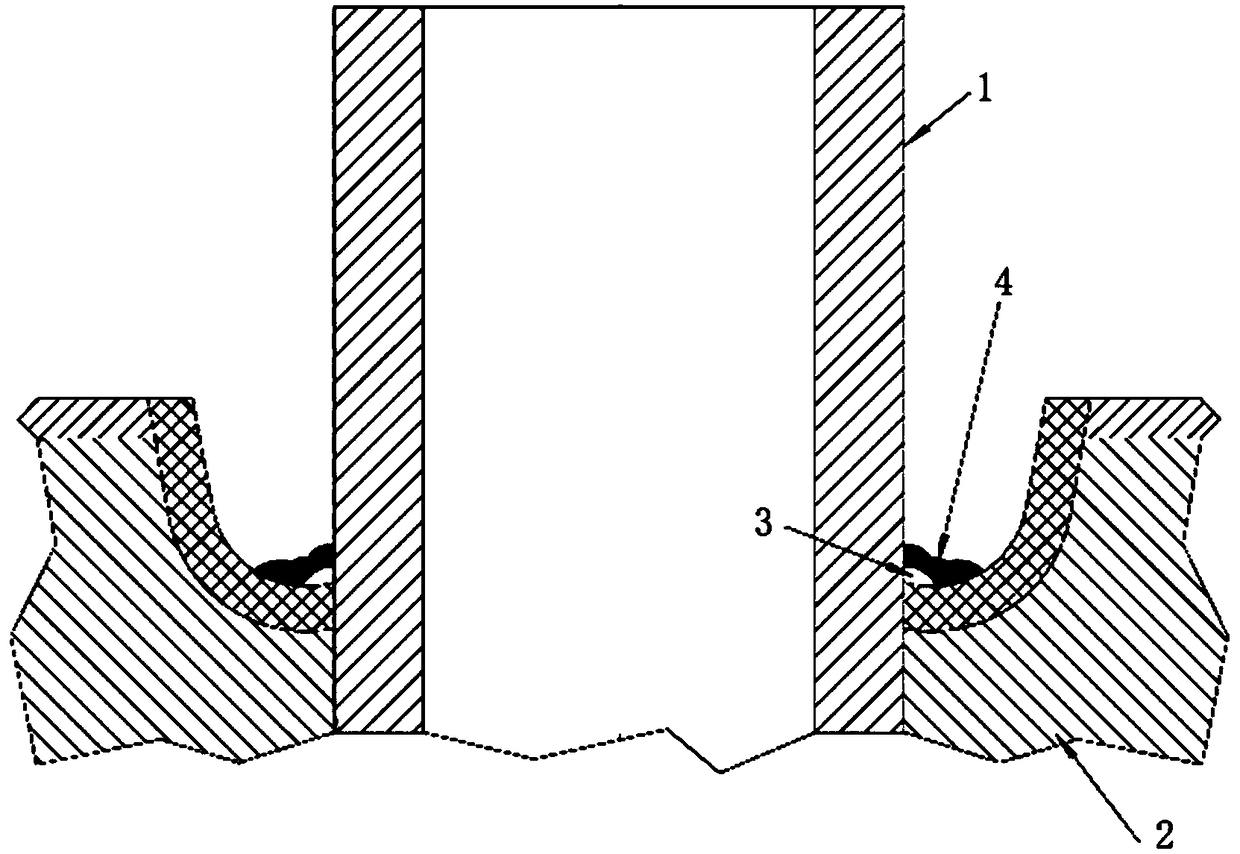

[0038] Example 1: Flat welding position welding of the J-groove weld connecting the pipe 1 and the head 2

[0039] 1. Root pass 3 welding:

[0040] 1) The bottoming weld bead 3 at the root is welded with an electrode with a diameter ≤ Φ2.5mm, close to the pipe wall, and adopts symmetrical welding, such as figure 1 shown;

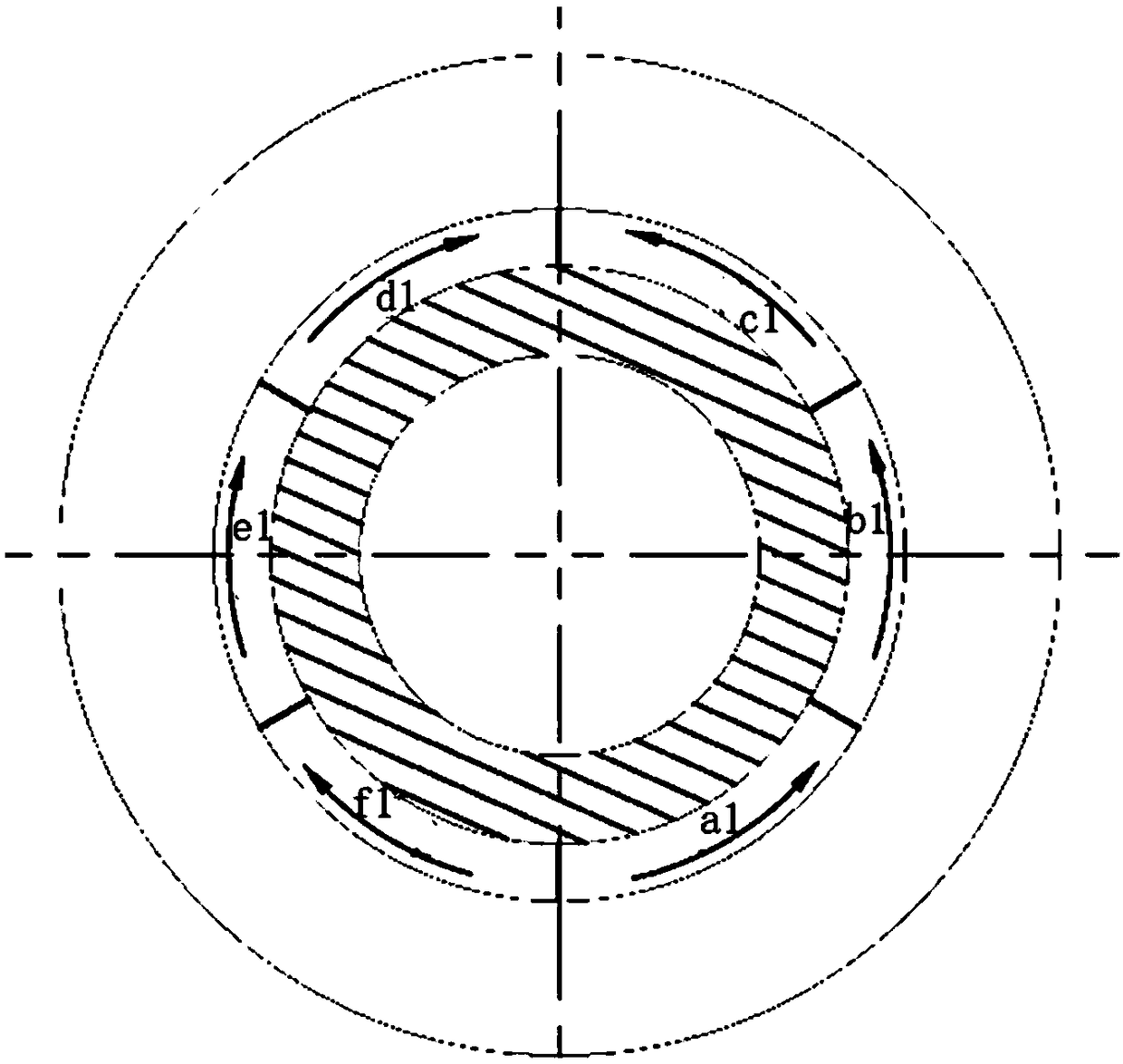

[0041] 2) if figure 2As shown, the root pass 3 is divided into six weld beads of equal arc length a1, b1, c1, d1, e1 and f1 in the counterclockwise direction on the circumference; during welding, a1→f1→b1→e1→c1 → The welding sequence of d1 is carried out, and the welding direction of a1, b1, c1 is counterclockwise, the welding direction of f1, e1, d1 is clockwise, and the welding arc of d1 covers 5 ~ 10mm above c1;

[0042] 3) During the welding process, each weld seam shall be ground after welding, using a pneumatic sand mill for grinding, and the number of sandpaper mesh is ≥ 60 mesh. After welding, it shall be ground for penetration (PT) testing, and ...

Embodiment 2

[0057] Example 2: Double-sided vertical upward welding of the J-groove weld connecting the pipe 1 and the head 2

[0058] 1. Root pass 3 welding:

[0059] 1) Root bottoming weld bead 3 is welded with an electrode with a diameter ≤ Φ2.5mm, close to the pipe wall, welded vertically upwards, and welded from the lowest position, such as Image 6 shown;

[0060] 2) Press Figure 7 As shown, the root pass 3 is divided into six weld beads of equal arc length, a2, b2, c2, d2, e2, f2, in the counterclockwise direction on the circumference; during welding, a2→b2→f2→c2→e2→ The welding sequence of d2 is carried out, and the welding direction of a2, b2, c2 is counterclockwise, the welding direction of f2, e2, d2 is clockwise, and the welding arc of d2 covers 5 ~ 10mm above c2;

[0061] 3) During the welding process, each weld seam shall be ground after welding, using a pneumatic sand mill for grinding, and the number of sandpaper mesh shall be ≥60 mesh; after welding, it shall be ground...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com