Special clamping tool for stepping board assembly and application method thereof

A special fixture and step plate technology, applied in the field of fixtures, can solve the problems of angle steel side bends that are not easy to straighten, difficult to correct, and slow assembly speed, etc., to achieve the effects of easy guarantee of engineering quality, saving mechanical equipment, and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The special clamp for step plate assembly of the present invention includes a top plate, a baffle plate, and an adjusting bolt.

[0043] see now Figure 4 and Figure 5 , Figure 4 It is a structural schematic diagram of a special clamp in an embodiment of the present invention, Figure 5 for Figure 4 Sectional view of A-A in Fig. As shown in the figure, the length of the top plate 3 is determined according to the width of the step plate, select 1100mm for use, top plate width 150mm, thickness 16mm rectangular steel plate;

[0044] The baffle plate is provided with two first baffle plate 4 and the second baffle plate 5 of the same size, both of which are rectangular steel plates with a width of 150 mm and a length of 100 mm. The first baffle plate 4 and the second baffle plate 5 are welded vertically on the The two ends of the lower surface of the top plate 3, the distance is determined according to the width of the step plate, and is selected as 1010mm; a through...

Embodiment 2

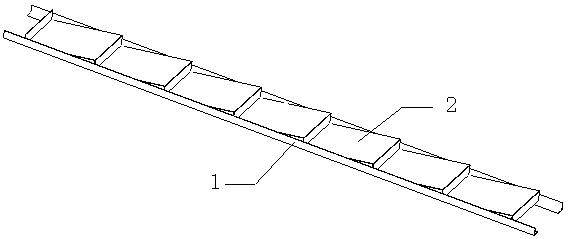

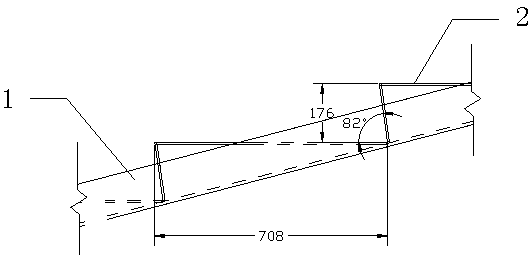

[0047] A method for using a special fixture for step plate assembly, the step plate is a ladder step composed of pattern plates or combined steel bearing plates, and ladder beams are arranged on both sides of the step step, including the following steps:

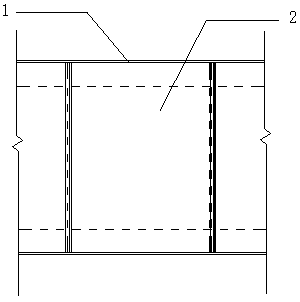

[0048] a. Provide an assembly platform 10, put the angle steel on the left side of the ladder beam 1 on the assembly platform, and draw a powder line 9 along the longitudinal length of the angle steel, so as to measure the longitudinal lateral curvature of the angle steel when assembling through the fixture; Figure 6 It is a schematic diagram of assembling the left angle steel according to the embodiment of the present invention.

[0049] b. Start to assemble the ladder steps and the angle steel on the right side of the ladder beam, install the first baffle plate 4 of the special fixture on the left angle steel, install the second baffle plate 5 of the special fixture on the right angle steel, and gradually tighten the adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com