Method for performing graphene material size separation by utilizing multilayer dialysis

A graphene and size technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem of grading the size of graphene materials, and achieve the effect of controllable separation and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Preparation of GO

[0041] Put 325 mesh graphite powder (2.0g) and concentrated sulfuric acid (70mL) into a 250mL flask, stir mechanically (200r.p.m) in an ice bath, and then slowly add KMnO 4 (7.0g) to keep the temperature of the suspension lower than 5°C for 30min; then, transfer the reaction system to a 35°C water bath and vigorously stir (300r.pm) for about 2h; then add 200mL of water, and then the solution Stir for 15h; then add 5mL H dropwise 2 O 2 (30%), the solution changed from dark brown to yellow; the mixture was filtered and washed with 5% HCl aqueous solution (50 mL three times) to remove metal ions, and washed with water to neutral; the obtained solid was dispersed in water to form 2 mg·mL -1 suspension.

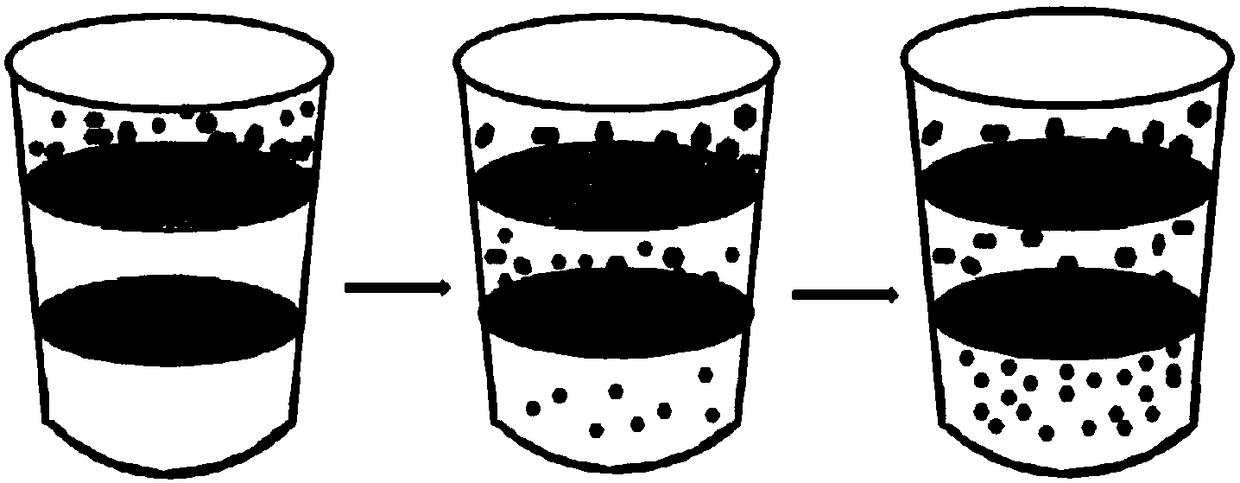

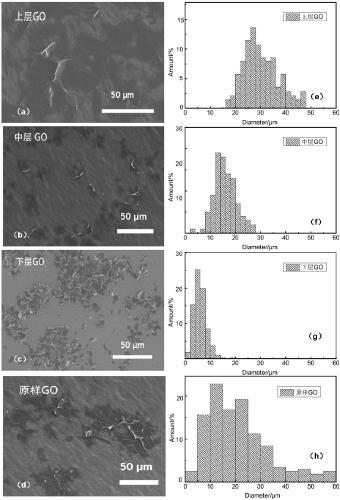

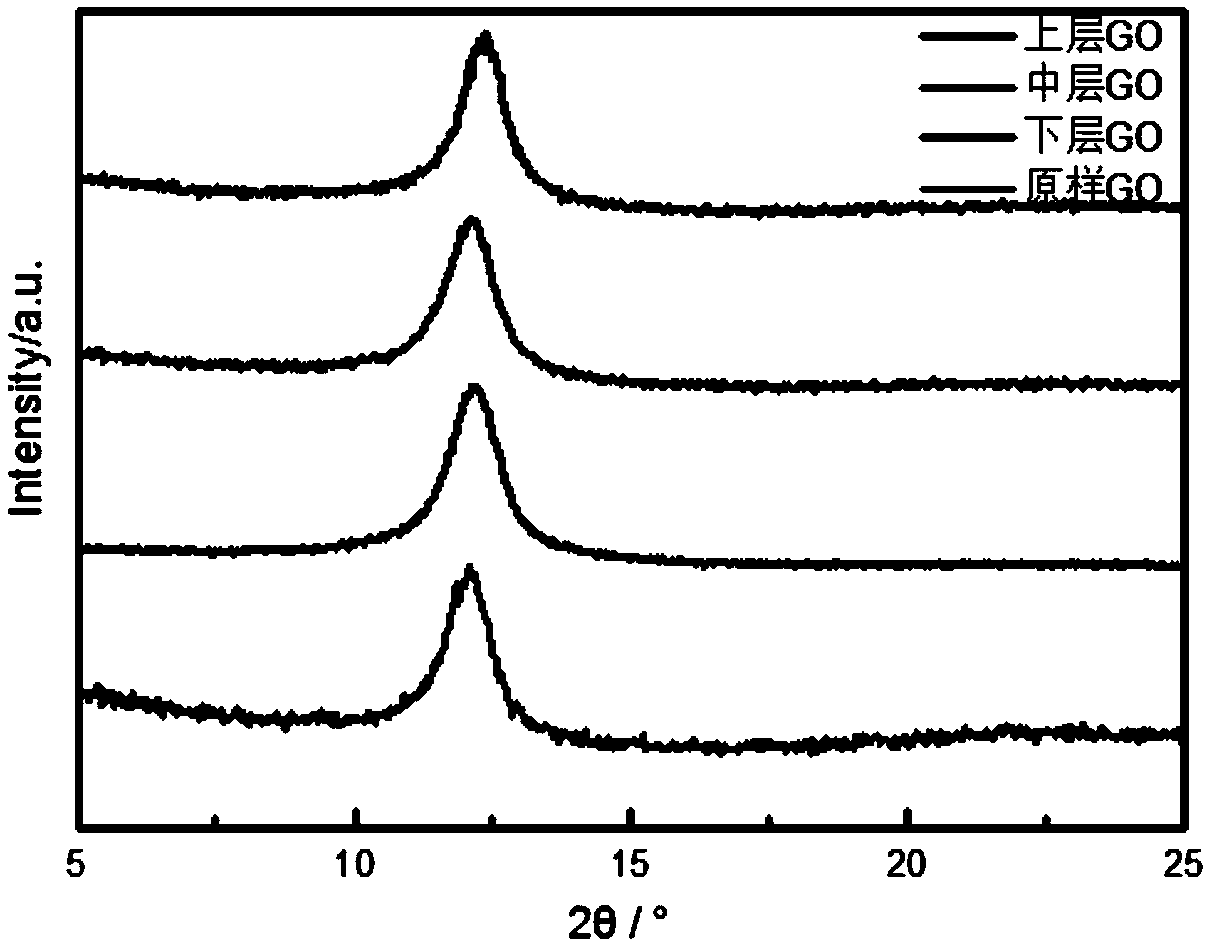

[0042] 2) Multilayer "dialysis" separation of GO

[0043] Clean the screen, layered and semi-fixed (semi-fixed means that the edges of the screen are fixed on the container and the screen is in a relaxed state) in a 50L bucket, and the upper layer is a scree...

Embodiment 2

[0058] 1) Preparation of GO

[0059] Put 800 mesh graphite powder (2.0g) and concentrated sulfuric acid (70mL) into a 250mL flask, stir mechanically (200r.p.m) in an ice bath, and then slowly add KMnO 4 (7.0g) to keep the temperature of the suspension below 5°C for 30 minutes. Then, the reaction system was transferred to a 35° C. water bath and vigorously stirred (300 r.p.m) for about 2 hours. Then 200 mL of water was added, and the solution was stirred for 15 h. Then add 5mL H dropwise 2 O 2 (30%), the solution changed from dark brown to yellow. The mixture was filtered and washed with 5% HCl aqueous solution (50 mL three times) to remove metal ions, and washed with water until neutral. The obtained solid is dispersed in water to form 2mg·mL -1 suspension.

[0060] 2) Multilayer "dialysis" separation of GO

[0061] Clean the sieve, layer and semi-fix it in a 20L bucket, the upper layer is 2000 mesh sieve, the lower layer is 8000 mesh, the distance between the layers is not fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com