Tempered fireproof explosion-proof glass and production process thereof

An explosion-proof glass and tempered glass technology, applied in glass/slag layered products, fire-retardant coatings, parallel glass structures, etc., can solve the problems of falling glass fragments, low strength, limited use range, etc. The effect of preventing glass fragments from falling, good heat insulation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

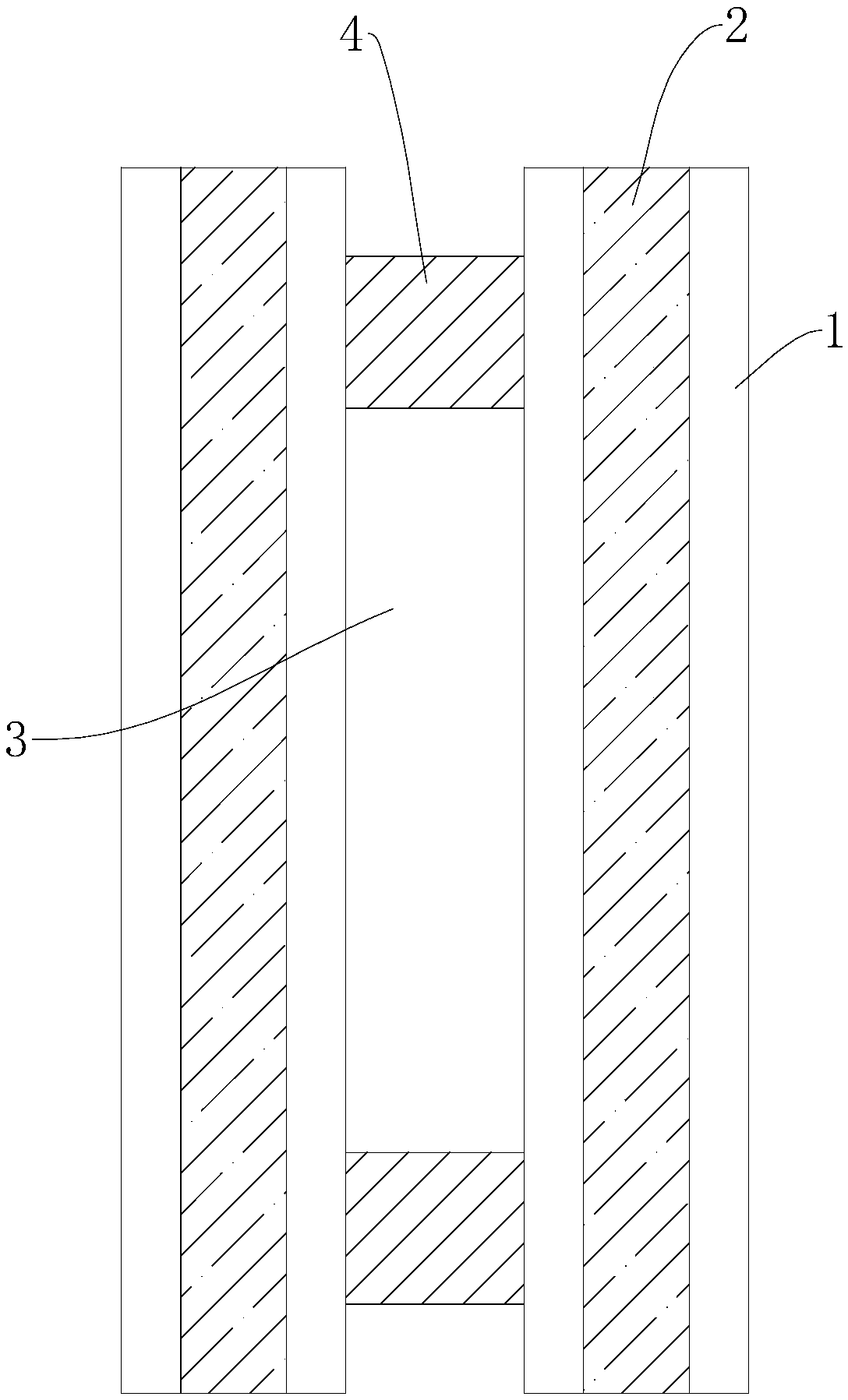

[0030] A kind of toughened fireproof explosion-proof glass, such as figure 1 As shown, it includes two laminated explosion-proof units, and the laminated explosion-proof unit includes two tempered glass slides 1, and the adjacent tempered glass slides 1 are connected by adhesive layer 2, and the adjacent laminated glass slides The explosion-proof units are supported and connected by aluminum grid bars 4 , and the two laminated explosion-proof units and the aluminum grid bars 4 form a vacuum compartment 3 .

[0031] The glass used in building doors and windows is generally a single piece of tempered glass. If it breaks, the broken glass particles will fall. In this solution, when the tempered glass slide breaks, the glass shards will adhere to the adhesive layer, which greatly reduces the falling of the glass shards. In addition, in this scheme, tempered glass sheets are used to form laminated glass, and then angled glass is used to form insulating glass, which can better play...

Embodiment 2

[0035] A process for manufacturing the tempered glass slide for tempered fireproof and explosion-proof glass of embodiment 1, comprising,

[0036] Cut into large slices, cut the glass raw materials into appropriate sizes, and obtain flake rough blanks;

[0037] Pretreatment, according to the shape and structure of the finished toughened glass slide, drilling, scribing, edge breaking, and polishing the sheet-like rough blank;

[0038] Washing and drying, cleaning and drying the pretreated slides;

[0039] Soften at high temperature, send the dried glass into the heating furnace for heating, the temperature in the furnace is 580℃~680℃, the heating time is 60s~180s according to the thickness of the glass, the smaller the thickness of the glass, the lower the temperature in the furnace;

[0040] Air grid quenching, when the thickness of the glass is 2mm, the furnace speed of the glass is not less than 540mm / s, and every time the glass thickness increases by 0.5mm, the furnace spe...

Embodiment 3

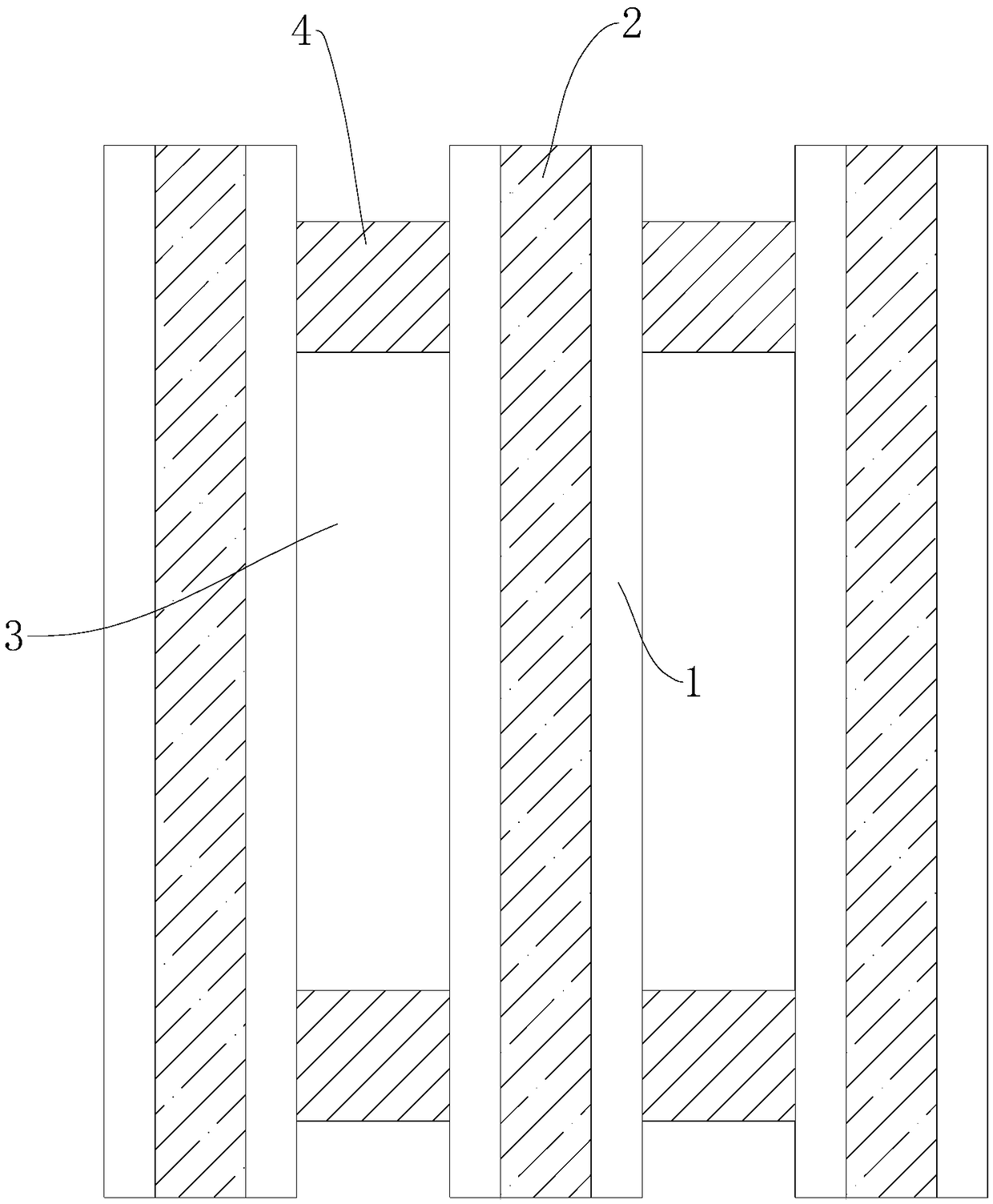

[0045] Such as figure 2 As shown, a tempered fireproof and explosion-proof glass differs from Example 1 in that it includes three laminated explosion-proof units, and the adjacent laminated explosion-proof units are supported and connected by aluminum grid bars 4, and the two laminated explosion-proof units are connected to the aluminum grid. The strip 4 encloses the vacuum compartment 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com