Method and device for controlling flow of zinc liquid in hot-dip galvanizing pot

一种流动控制、热镀锌的技术,应用在对表面涂布液体的装置、热浸镀工艺、涂层等方向,达到防止锌资源消耗、减少人工操作、避免堆积结块的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

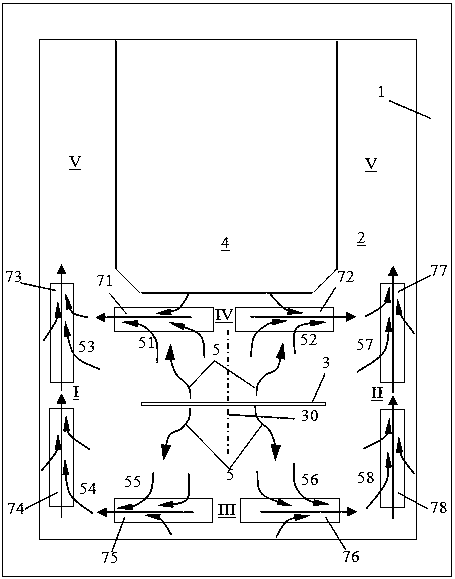

[0038] see figure 2 A total of 8 sections of traveling wave magnetic field generators are installed on the left and right sides of the zinc pot 1 hot-dip area (area I and area II), the front end (area III) and the position between the strip steel 3 and the furnace nose 4 (area IV). Respectively: the first left segment traveling wave magnetic field generator 73, the second left segment traveling wave magnetic field generator 74, the first right segment traveling wave magnetic field generator 77, the second right segment traveling wave magnetic field generator 78, the first front segment traveling wave magnetic field generator 75, the first Two rear traveling wave magnetic field generators 76 , a first rear traveling wave magnetic field generator 71 , and a second rear traveling wave magnetic field generator 72 .

[0039] The first left segment traveling wave magnetic field generator 73, the second left segment traveling wave magnetic field generator 74, the first front segment...

Embodiment 2

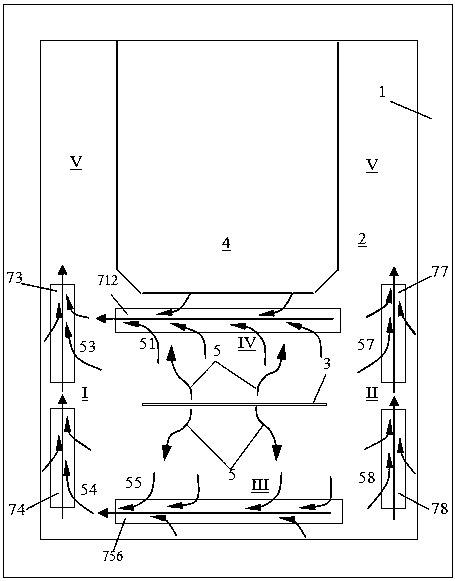

[0047] see image 3 , the transversely arranged traveling wave magnetic field generator located at the front end of the zinc pot (Zone III) and the position between the strip steel and the furnace nose (Zone IV) is a full-length type, that is, the front traveling wave magnetic field generator 756 and the rear traveling wave magnetic field generator 756 Magnetic field generator 712, and the direction of the traveling wave magnetic field excited by the whole length type traveling wave magnetic field generator is in the same direction, so as to drive the zinc liquid to flow to a certain side of the zinc pot, and generate The liquid zinc flow is connected, and the liquid zinc driven by the transverse traveling wave magnetic field generator is turned and driven to the rear end of the zinc pot (V zone).

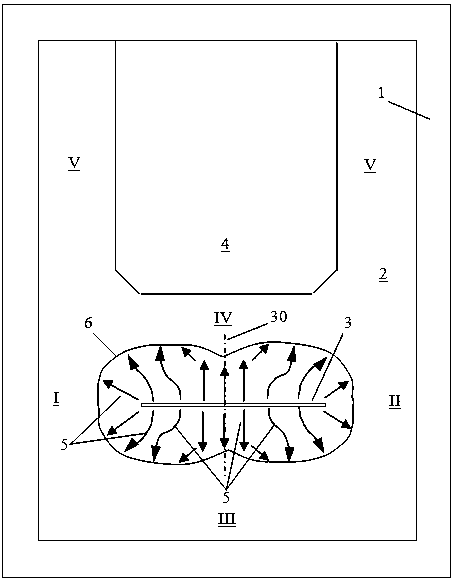

[0048] Depend on figure 1 It can be seen that in the prior art, under the blowing action of the air knife, the liquid zinc flows obliquely along the center line of the strip to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com