Microwave drying machine with movable and adjustable magnetrons

A microwave dryer, microwave drying technology, applied in dryers, drying solid materials, heating to dry solid materials and other directions, can solve the problems of reducing drying quality, insufficient drying energy, low drying efficiency, etc., to ensure drying quality and High efficiency, high utilization rate of microwave energy, and the effect of reducing drying energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

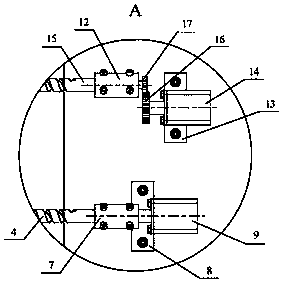

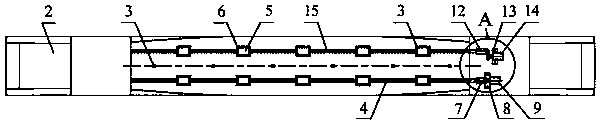

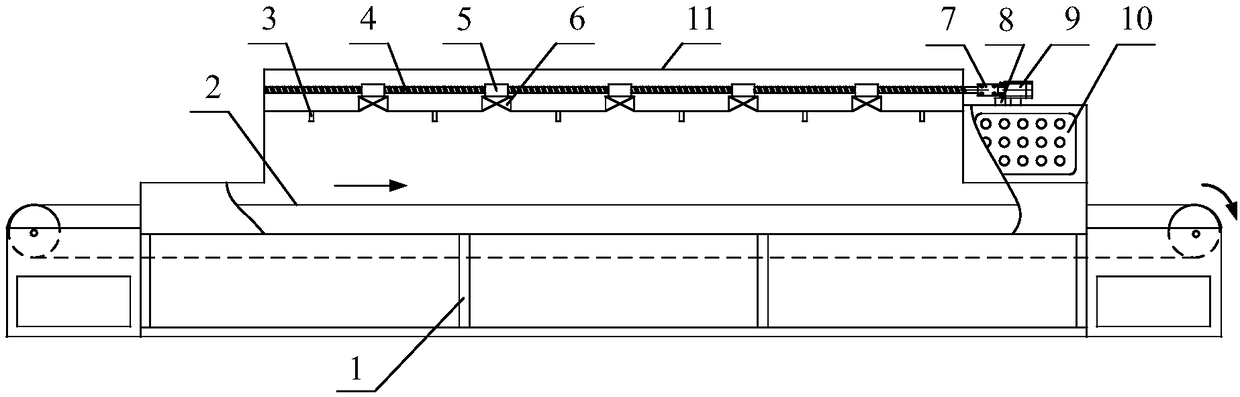

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A microwave dryer whose magnetron position can be moved and adjusted includes a frame 1, a rotary material conveyor belt assembly 2 and a microwave drying chamber 11 mounted on the upper side of the frame 1, the rotary material The middle part of the conveyor belt assembly 2 runs through the cavity of the microwave drying chamber 11 and is accommodated. On the upper side of the cavity of the microwave drying chamber 11, the upper part of the rotary material conveyor belt assembly 2 is longitudinally connected to each other. The lead screw I4 and the lead screw II15 are installed in parallel and rotatable, and N screw nut type tube holders 5 are equipped on the lead screw I4 and the lead screw II15 respectively axially movable, and the magnetron 6 is fixed on the wire On the female socket 5, a plurality of temperature sensors 3 are evenly distributed sequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com