Automatic dissolving and cleaning device for chemical quantitative analysis of fiber content of textile

A textile fiber, quantitative analysis technology, applied in the direction of analyzing materials, instruments, etc., to achieve the effect of improving test efficiency, increasing the scope of use, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

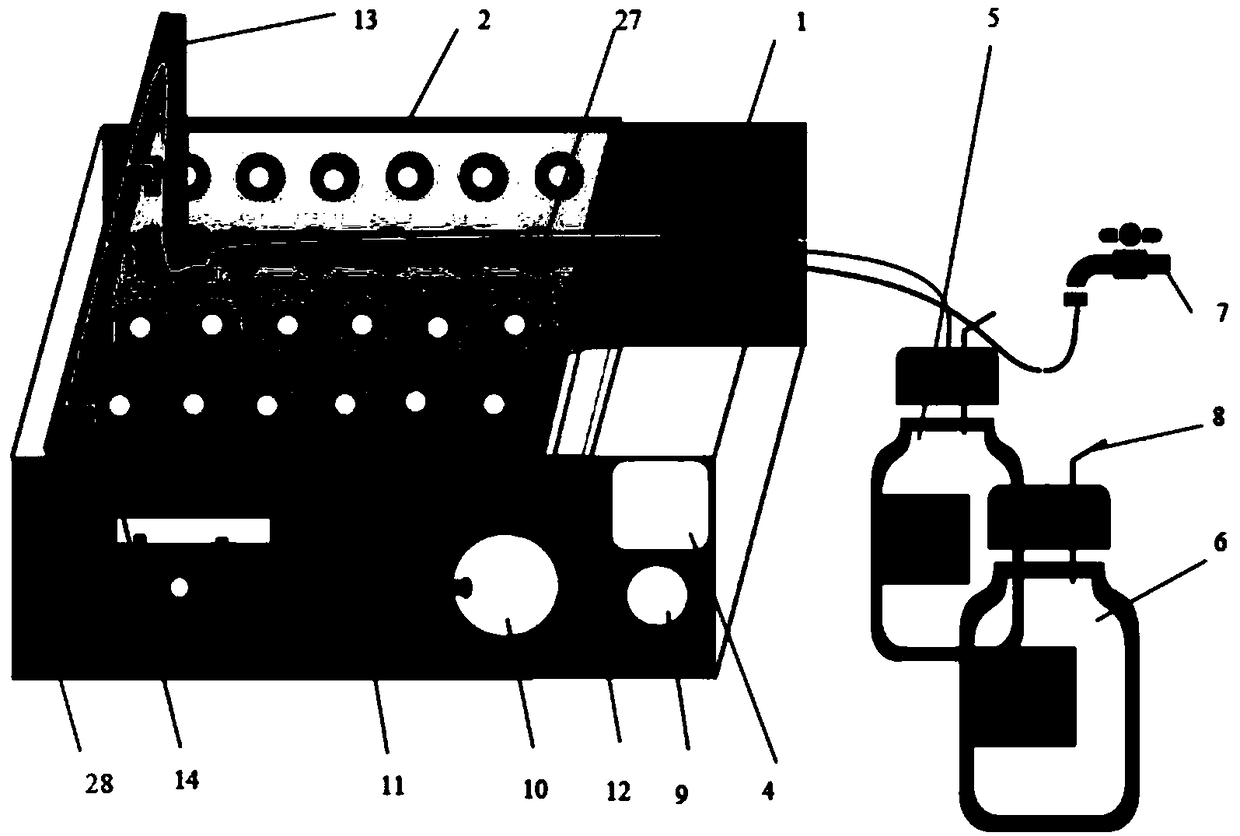

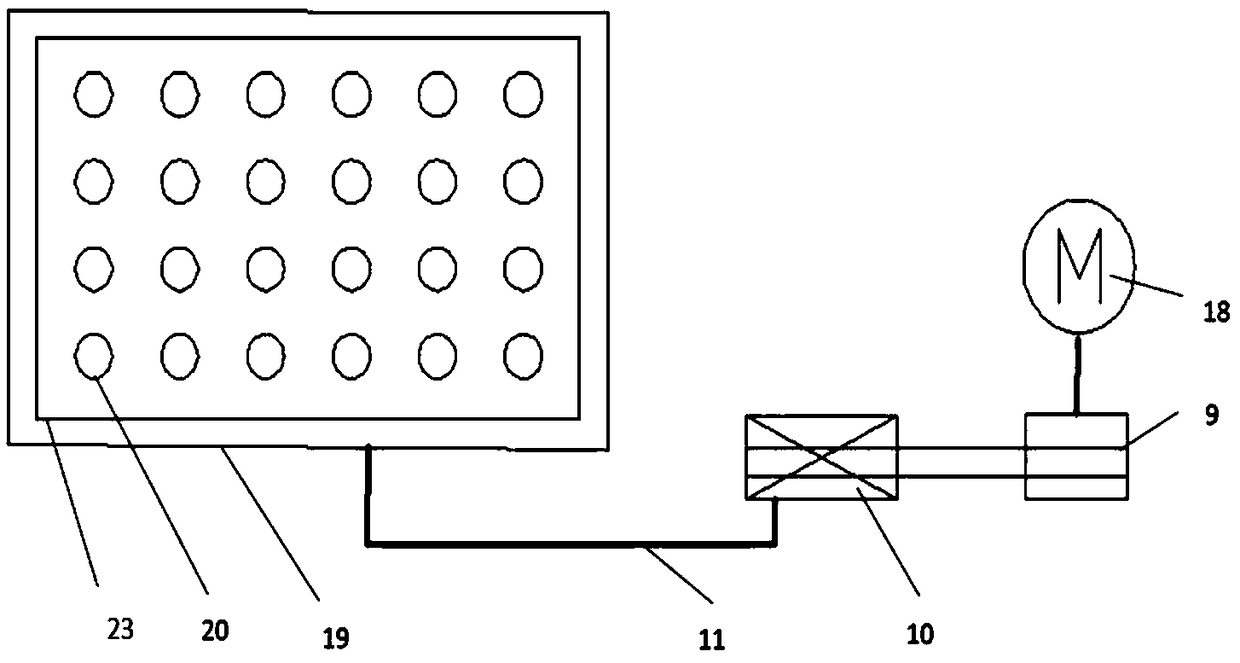

[0033] An automatic dissolving and cleaning device for chemical quantitative analysis of textile fiber content, comprising an outer box body 28, a liquid adding mechanism, an oscillating mechanism 2, a liquid draining mechanism, an integrated control display mechanism 4, and a siphon conical flask 21. The liquid adding mechanism includes Filling pipe 27, filling port 14, automatic quantitative liquid adding controller 1, bracket 13, transmission device I, solution storage bottle 5, neutralization solution storage bottle 6, cleaning solution supply end 7; the oscillation mechanism 2 is located at In the outer box 28, and close to the automatic quantitative dosing controller 1 side, the oscillating mechanism 2 includes a transmission device II, a tray 23, a siphon conical flask clamp 20, and an oscillating box 19, and the tray 23 is located in the oscillating box 19. Take out or insert the vibration box 19 in a drawer type, and the siphon conical flask clamp 20 is fixedly connect...

Embodiment 2

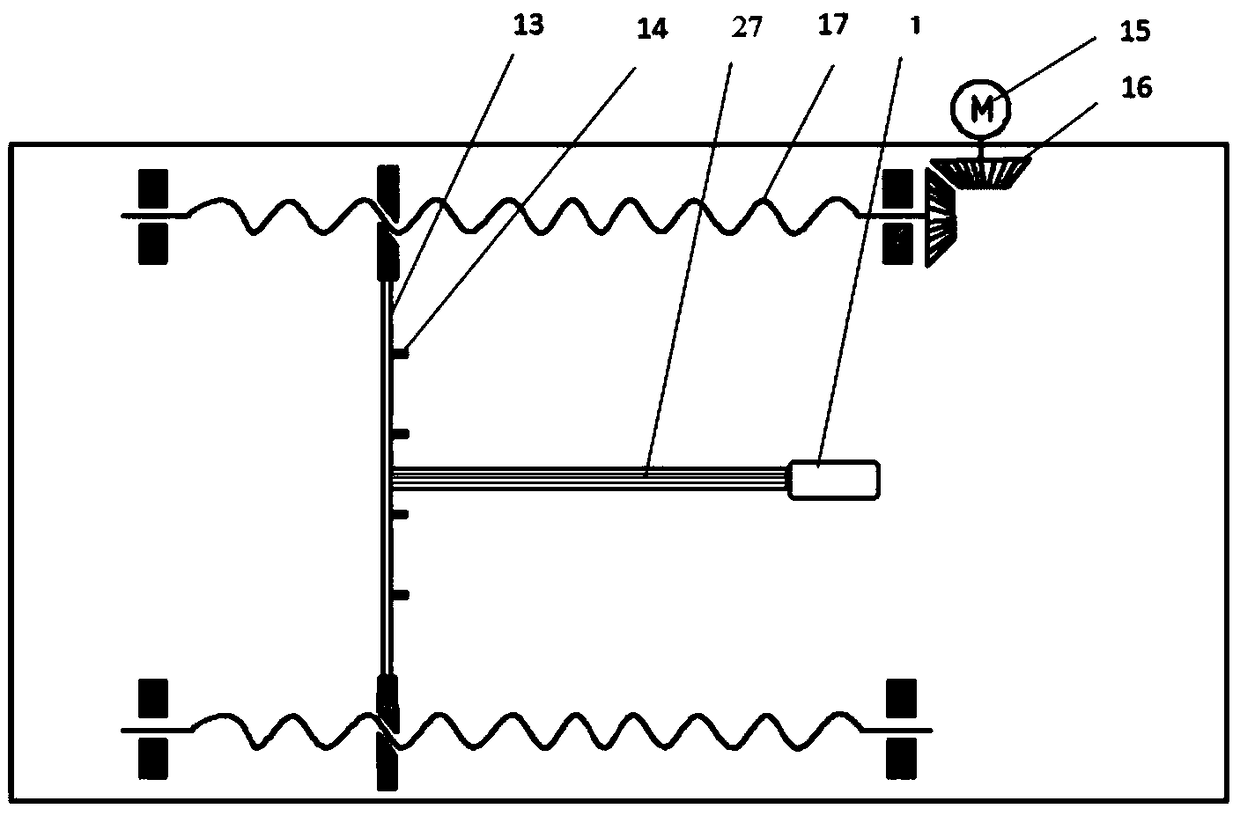

[0036]The automatic dissolving and cleaning device for chemical quantitative analysis of textile fiber content described in this embodiment is similar to that of Embodiment 1 and will not be repeated. The difference is that at least four horizontal bars of the bracket 13 are arranged side by side Filling port 14, the specific number of which depends on the number of horizontal siphon conical flasks, is used to guide and fix the filling pipe; the transmission device I includes a drive motor I15 and a transmission rod I17, and is close to the automatic quantitative liquid addition control On one side of the device, the driving motor I15 is arranged on the outside of the outer box 28, and the transmission rod I is arranged on the inside of the outer box 28 and above the oscillation mechanism; the driving motor I15 passes through the straight-toothed bevel gear 16 Drive the transmission rod I17 to rotate, and then push the bracket 13 to move left and right to automatically add liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com