Field data collection system and method for dairy product workshop

A technology of on-site data and on-site collection, applied in the general control system, control/regulation system, program control, etc., can solve the problems of wasting workers' time, many containers, distortion, etc., and achieve the effect of easy wearing, avoiding distortion, and increasing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Further detailed explanation through specific implementation mode below:

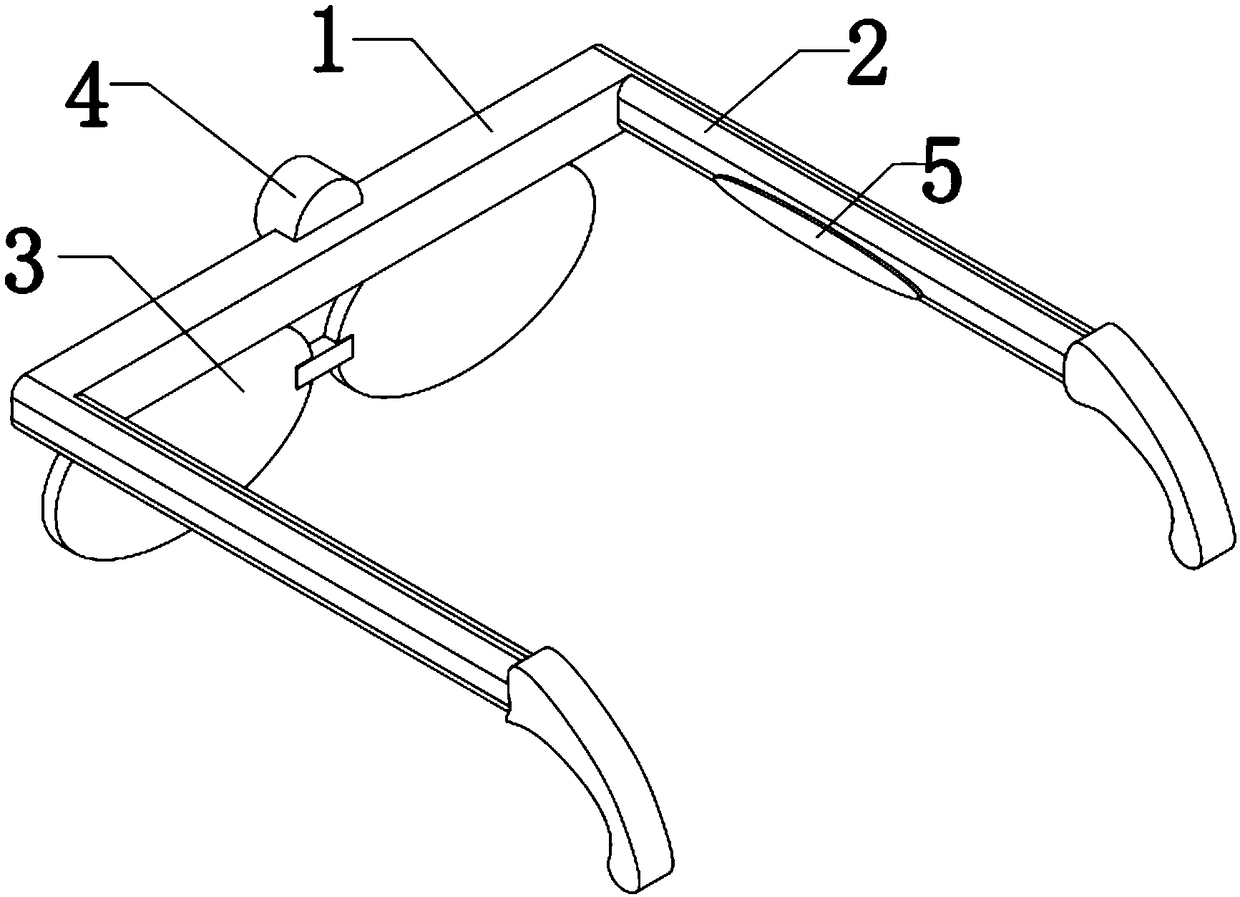

[0034] The reference signs in the drawings of the specification include: mirror frame 1 , mirror feet 2 , lens 3 , camera 4 , and electrode sheet 5 .

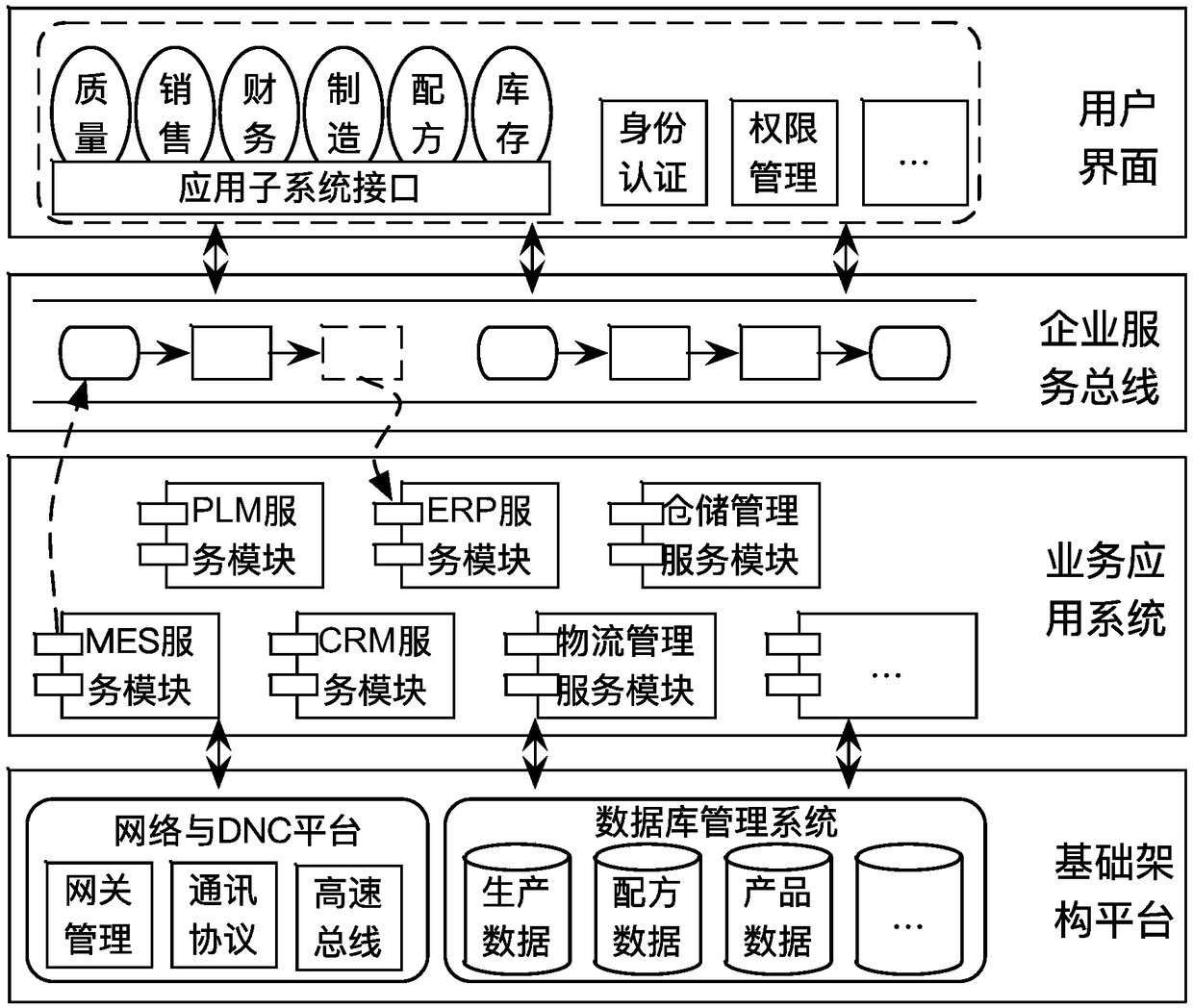

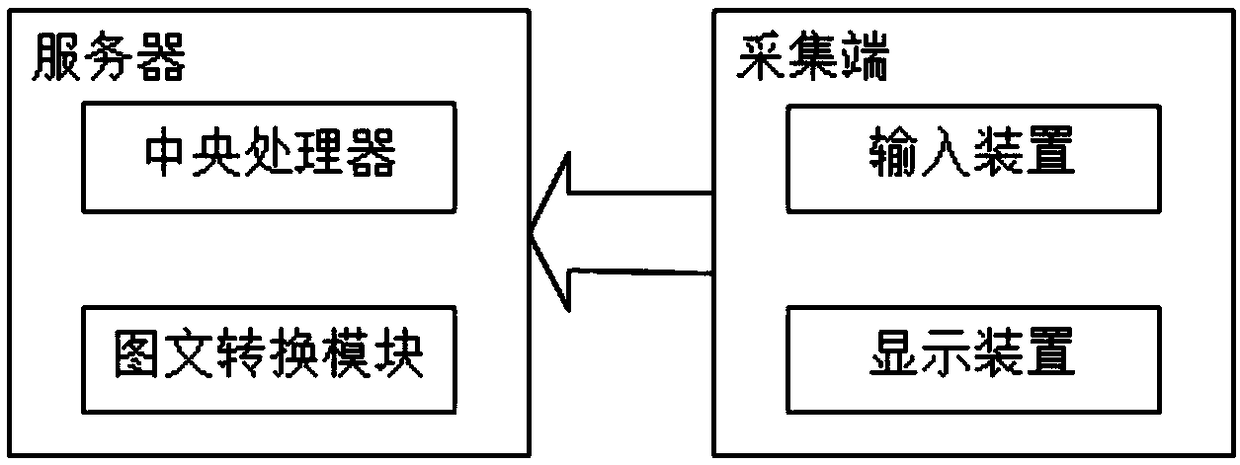

[0035] The embodiment is basically as attached figure 1 Shown: The on-site data acquisition system of the dairy workshop is a part of the information integration system in the intelligent production workshop. The information integration system of the intelligent workshop mainly adopts an information integration solution based on service-oriented architecture (SOA). The coupling structure integrates the various business systems of the enterprise into a unified platform, realizes information sharing between various businesses, and meets the needs of information system integration from the enterprise management level to the workshop management level.

[0036] The infrastructure platform provides the hardware and software infrastructure required for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com