SOT-89/223-2L lead frame and preparation method of two-pin structure

A 1.SOT-89, 2.SOT-89 technology, applied in the field of preparation of SOT-89/223-2L lead frame and two-leg structure, can solve problems such as circuit failure, ignition or short circuit, and improve reliability. performance, reduce investment, and broaden the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

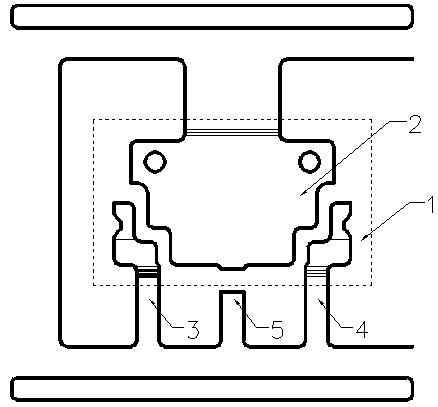

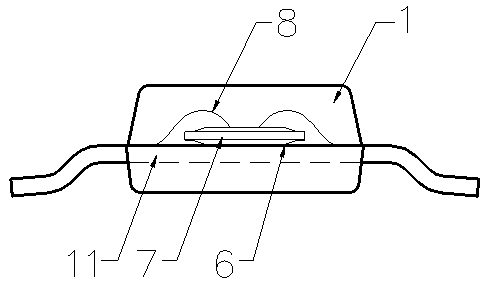

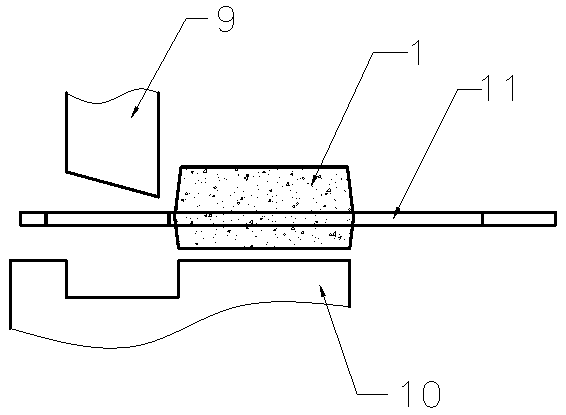

[0021] The invention provides a method for realizing the SOT-89 / 223-2L lead frame and the two-leg structure. Through the special frame structure design, the plastic sealing mold can be compatible with SOT-89 / 223-3L and SOT-89 / 223-2L during plastic sealing For products with two structures, the middle lead pins of SOT-89 / 223-2L products are completely encapsulated in the plastic package after plastic sealing, and the middle lead pins that play the role of plastic sealing on the frame are cut off by the mold during glueing, and the middle lead pins of the SOT-89 / 223-2L product The 0.1mm length of molding compound is left at the middle lead pin of the 223-2L product, which doubles the lead pitch of the device and improves the reliability of the device.

[0022] Such as figure 1 As shown, the SOT-89 / 223-2L lead frame and two-leg structure include a plastic package body 1, a lead frame 11 is set inside the plastic package body 1, a heat sink 2 is drawn out from one side of the plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com