Corn plant pesticide spraying device suitable for scale planting field

A technology for planting fields and corn, applied to devices for capturing or killing insects, applications, animal husbandry, etc., can solve the problems of low spraying efficiency, high cost, and difficult adjustment of spraying angle, etc., to increase the scope of spraying , improve efficiency, and increase the effect of spraying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

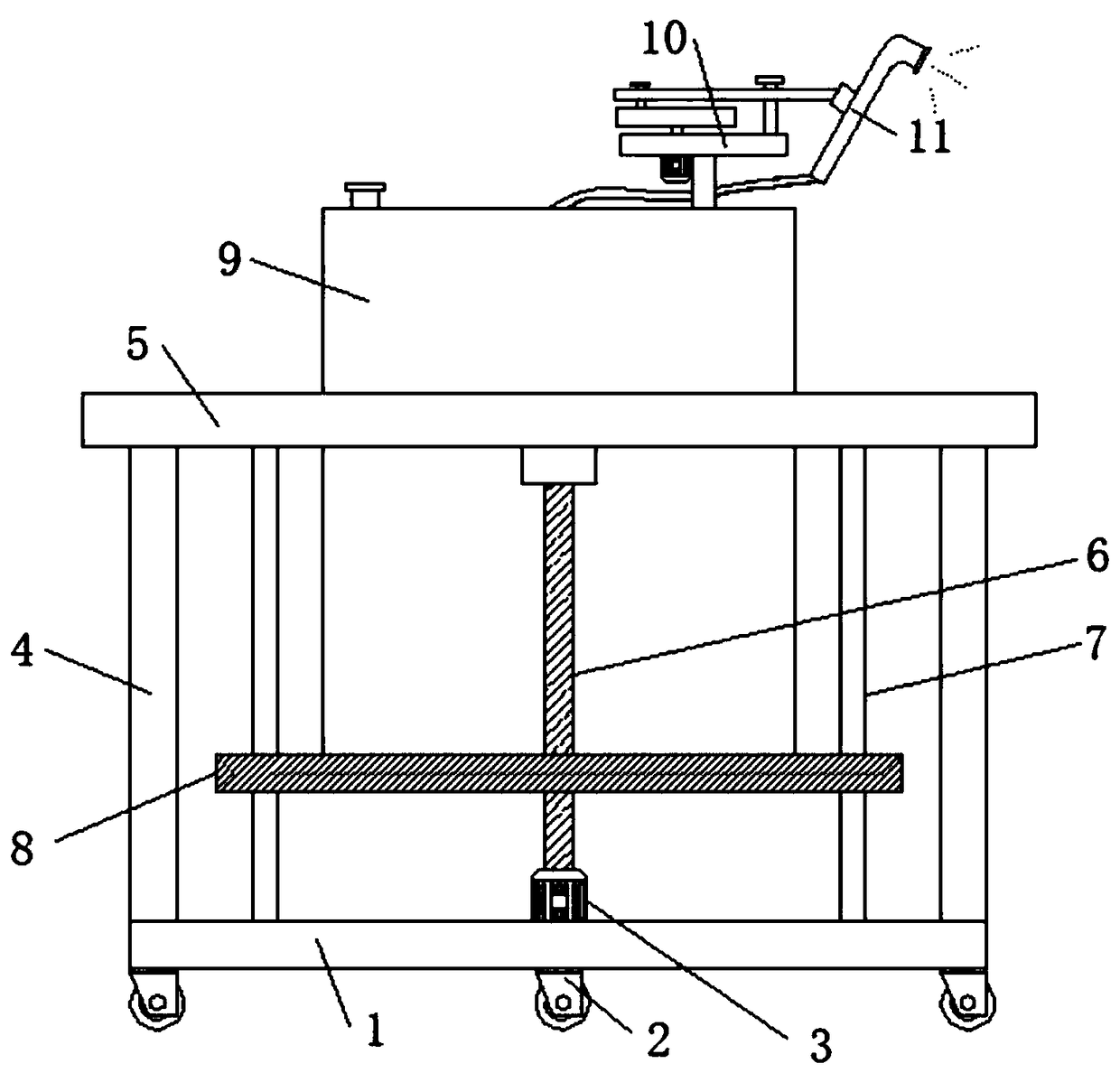

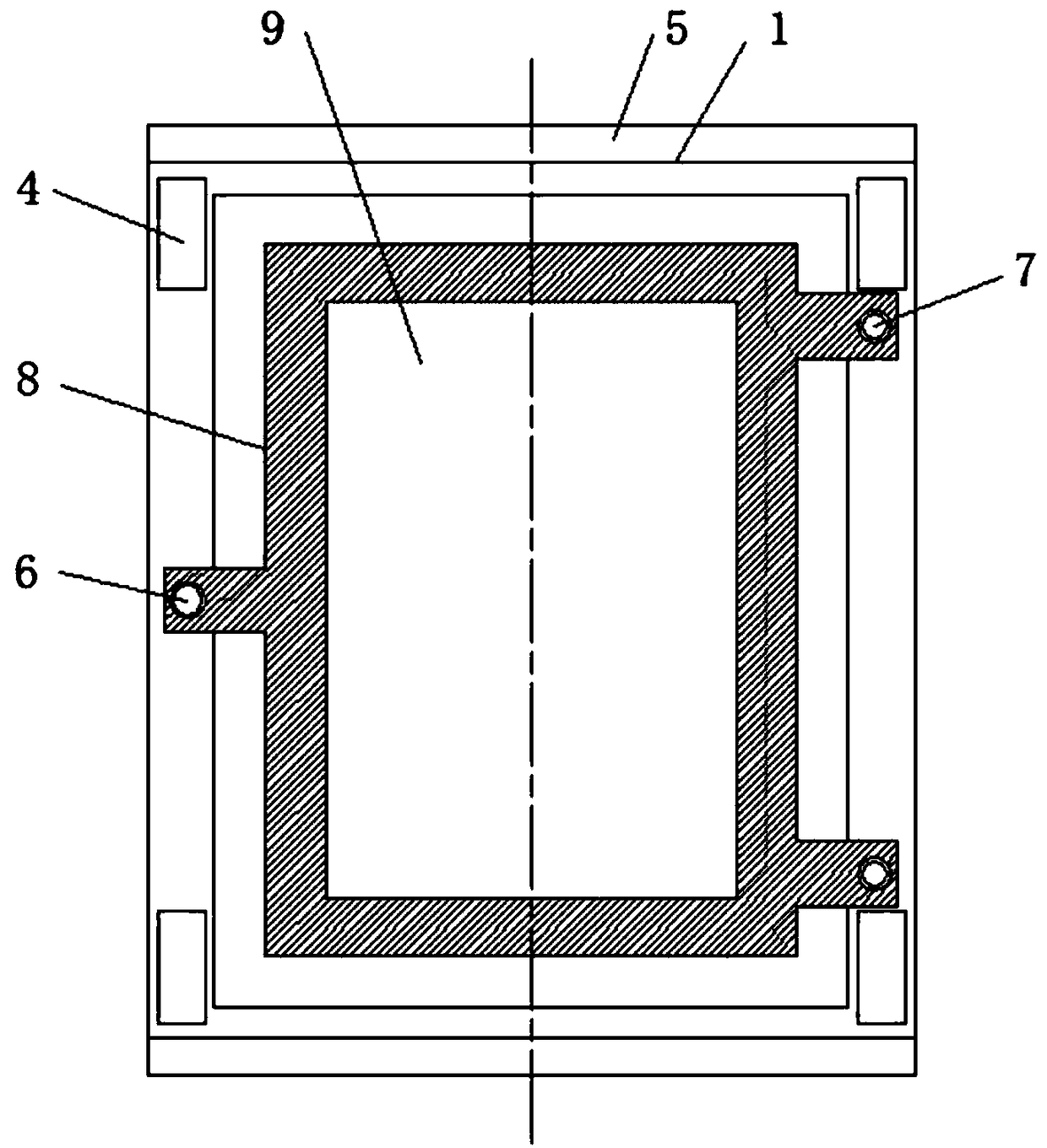

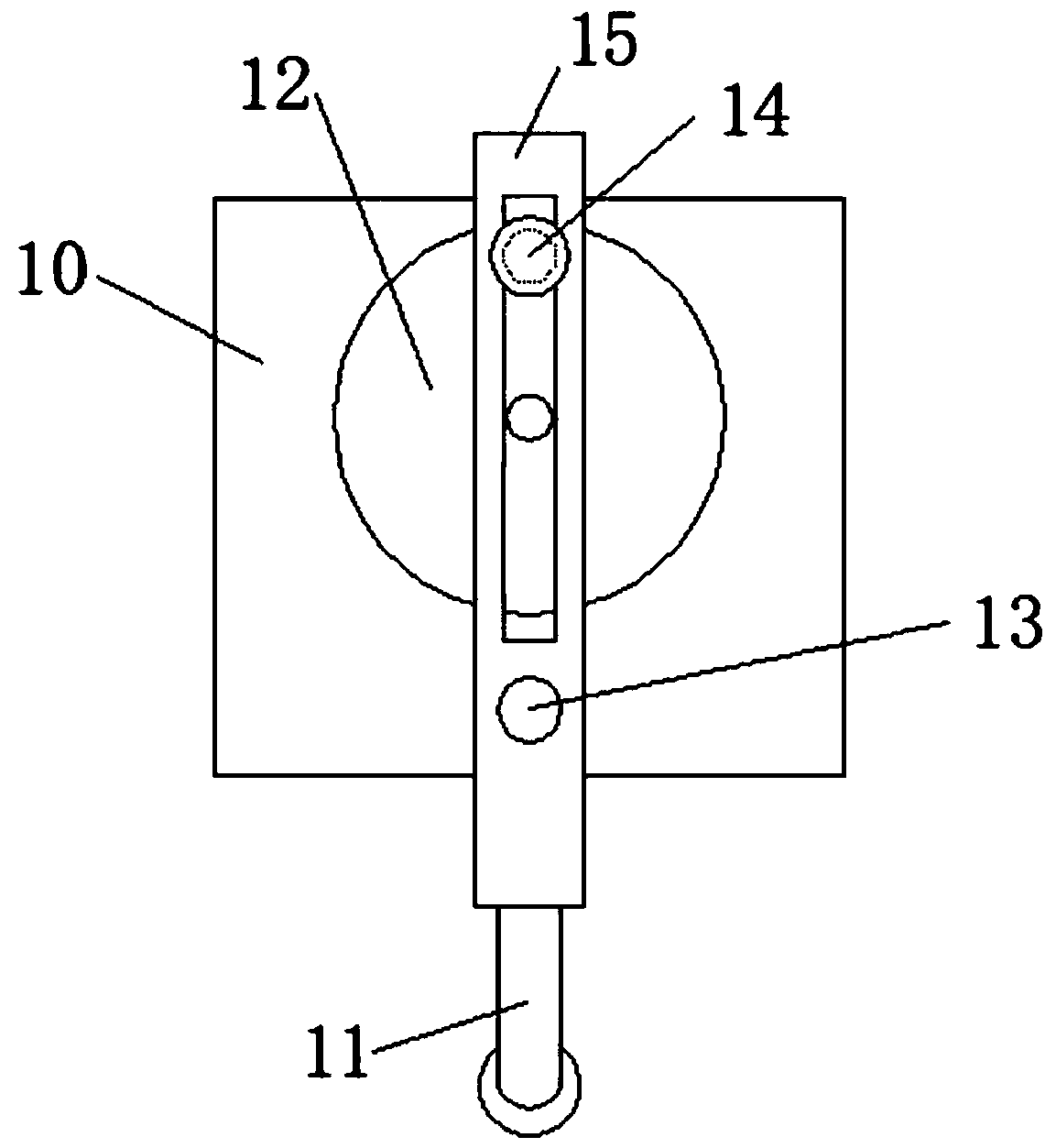

[0025] Embodiment 1, with reference to Figure 1-4 , a corn plant spraying device suitable for large-scale planting fields, including a base 1, rollers 2 are installed on both sides of the bottom of the base 1, a bidirectional motor 3 is installed in the middle of the top of the base 1, and both sides of the top of the base 1 are Two vertical struts 4 are welded, and the top between the four vertical struts 4 is connected with a fixed frame 5, and a vertically arranged screw rod 6 and a guide rod 7 are connected between the base 1 and the fixed frame 5, wherein the guide rod 7 Located on both sides of the screw rod 6, a support plate 8 arranged horizontally is connected between the screw rod 6 and the guide rod 7, a spray box 9 is installed on the top of the support plate 8, and a support frame 10 is installed on one side of the top of the spray box 9, One side of the support frame 10 is provided with a nozzle 11 connected to the spray box 9, and the top of the support frame 1...

Embodiment 2

[0028] Embodiment 2, with reference to Figure 2-6 , a corn plant spraying device suitable for large-scale planting fields, including a base 1, rollers 2 are installed on both sides of the bottom of the base 1, a bidirectional motor 3 is installed in the middle of the top of the base 1, and both sides of the top of the base 1 are Two vertical struts 4 are welded, and the top between the four vertical struts 4 is connected with a fixed frame 5, and a vertically arranged screw rod 6 and a guide rod 7 are connected between the base 1 and the fixed frame 5, wherein the guide rod 7 Located on both sides of the screw rod 6, a support plate 8 arranged horizontally is connected between the screw rod 6 and the guide rod 7, a spray box 9 is installed on the top of the support plate 8, and a support frame 10 is installed on one side of the top of the spray box 9, One side of the support frame 10 is provided with a nozzle 11 connected to the spray box 9, and the top of the support frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com