Foodstuff processing machine pulping capacity determination device

A technology for food processing machines and determining devices, which is applied in household appliances, applications, kitchen appliances, etc., can solve the problems of single water level detection, reduce product competitiveness, increase the cost of the whole machine, etc., to improve detection accuracy and improve water level detection accuracy. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

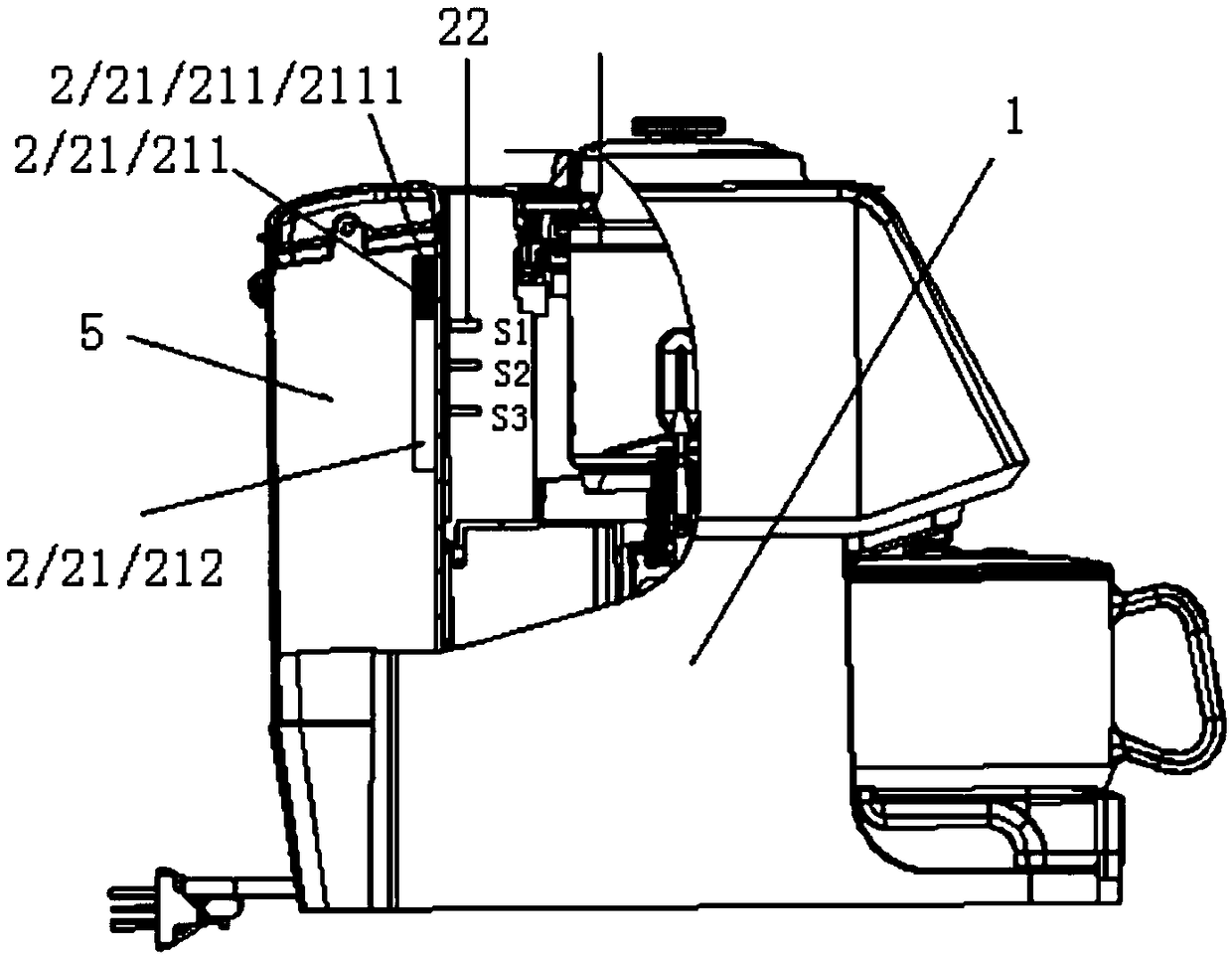

[0049] In this embodiment, on the basis of the first embodiment, the specific arrangement of the bar magnet 2111 is introduced in detail.

[0050] Optionally, the length direction of the bar magnet 2111 is set along the vertical direction;

[0051] When the length of the magnet 2111 is less than or equal to the distance between any two adjacent reed switches 22, the switch state changes of different reed switches 22 correspond to different water levels, and the switch state of each reed switch 22 changes One-to-one correspondence with each water level;

[0052] When the length of the magnet 2111 is greater than the distance between any two adjacent reed switches 22, different switch state change combinations of multiple reed switches 22 correspond to different water level ranges, and each switch state change combination is related to each A water level range corresponds one by one.

[0053] In the embodiment of the present invention, the length of the magnet 2111 can be rela...

Embodiment 3

[0056] In this embodiment, on the basis of the first or second embodiment, the scheme of judging the current water level according to the change of the switch state of different reed switches is introduced in detail.

[0057] Optionally, the plurality of reed switches include: a first reed switch S1, a second reed switch S2, and a third reed switch S3 arranged sequentially from top to bottom;

[0058] The main control unit 4 judges the current water level according to the change of the switch state of different reed switches and may include:

[0059] When the main control unit 4 detects that the switch state of the first reed switch S1 changes, and the switch states of the second reed switch S2 and the third reed switch S3 do not change, it is determined that the current water level remains within the first water level range ;

[0060] When the main control unit 4 detects that the switch states of the first reed switch S1 and the second reed switch S2 change, and the switch s...

Embodiment 4

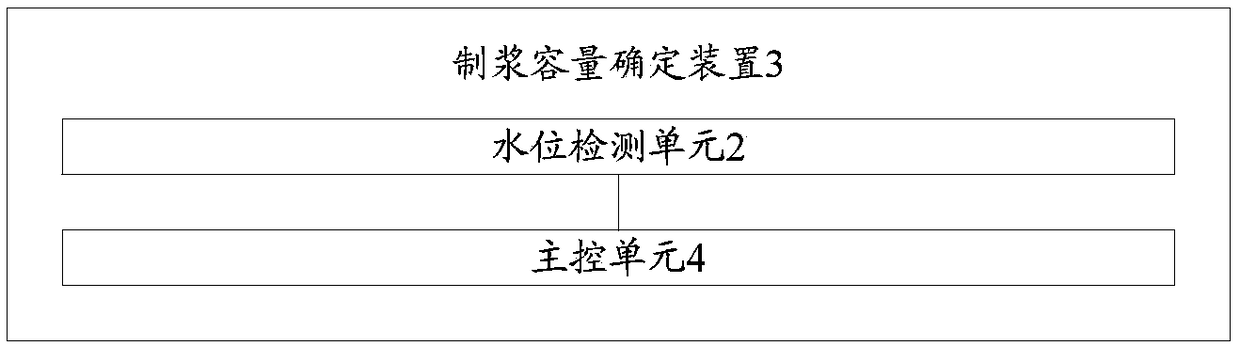

[0066] On the basis of the third embodiment, this embodiment introduces in detail the scheme of determining the pulping capacity currently selectable by the user according to the current water level of the water tank.

[0067] Optionally, the main control unit 4 determining the pulping capacity currently selectable by the user according to the current water level of the water tank may include:

[0068] Comparing the amount of water indicated by the current water level to one or more preset pulping capacities of the food processor;

[0069] The pulping capacity of one or more pulping capacities that is smaller than the water amount is taken as the pulping capacity currently selectable by the user.

[0070] In the embodiment of the present invention, the embodiment in the third embodiment is still used as an example for illustration, and it is assumed that S1, S2, and S3 correspond to 1000ml, 800ml, and 600ml respectively, and it is assumed that the water volume requirement for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com