Hinged knee prosthesis

A knee joint prosthesis, hinged technology, applied in the direction of the knee joint, prosthesis, elbow joint, etc., can solve the problems of inability to achieve internal rotation and external rotation, and reduce the flexibility of the hinged knee joint prosthesis. To achieve the effect of improving the flexibility of use, facilitating the promotion and application, and safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

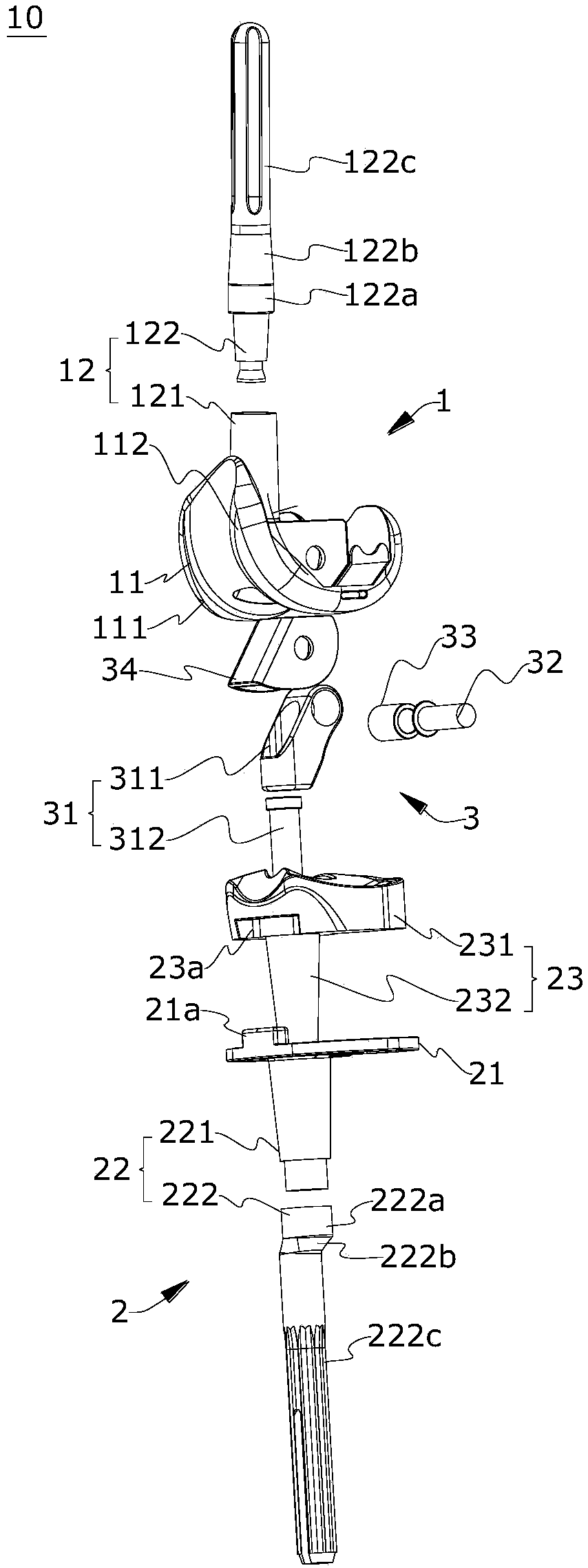

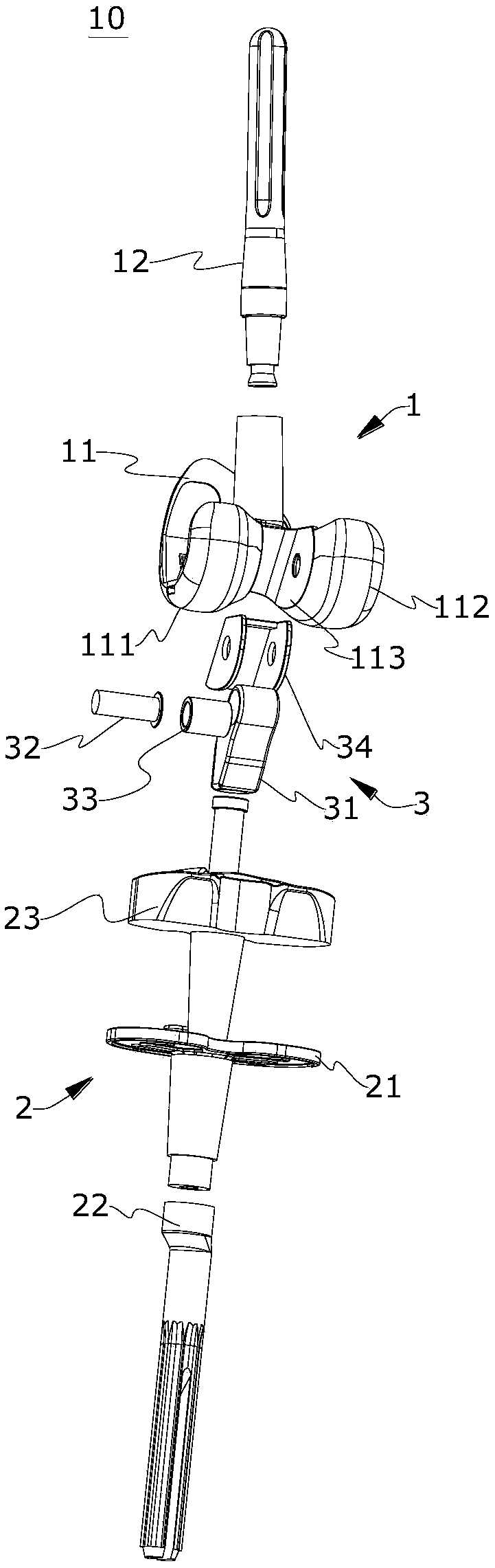

[0012] figure 1 shows an exploded schematic diagram of a hinged knee prosthesis according to an embodiment of the present invention; figure 2 The exploded schematic view of the hinged knee joint prosthesis according to the embodiment of the present invention is shown again in different viewing angles. Such as figure 1 and figure 2 As shown, the hinged knee prosthesis 10 mainly includes a femoral component 1 and a tibial component 2 that cooperate with each other, and a hinge component 3 for articulating the femoral component 1 and the tibial component 2 .

[0013] The femoral component 1 includes a femoral condyle 11 and a femoral pin 12 connected to each other. The femoral condyle 11 is mainly manufactured according to the anatomical shape and structure of the human femur, and the manufacturing material is preferably cobalt-chromium-mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com