Novel panty-shape diaper product and production technology thereof

A production process and product technology, applied in medical science, clothing, underwear, etc., can solve problems such as insufficient comfort, and achieve the effects of improving sealing rate, quality, and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

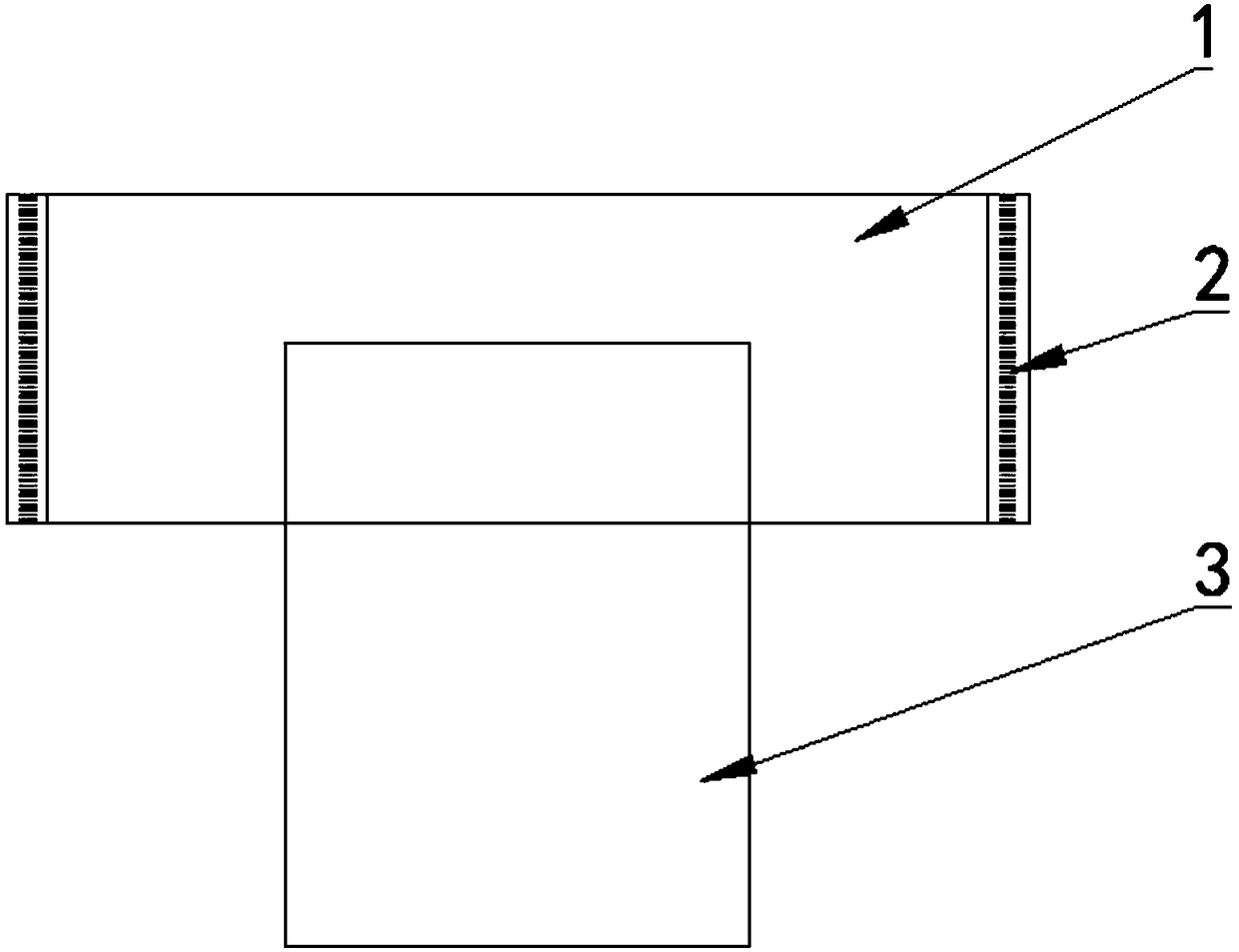

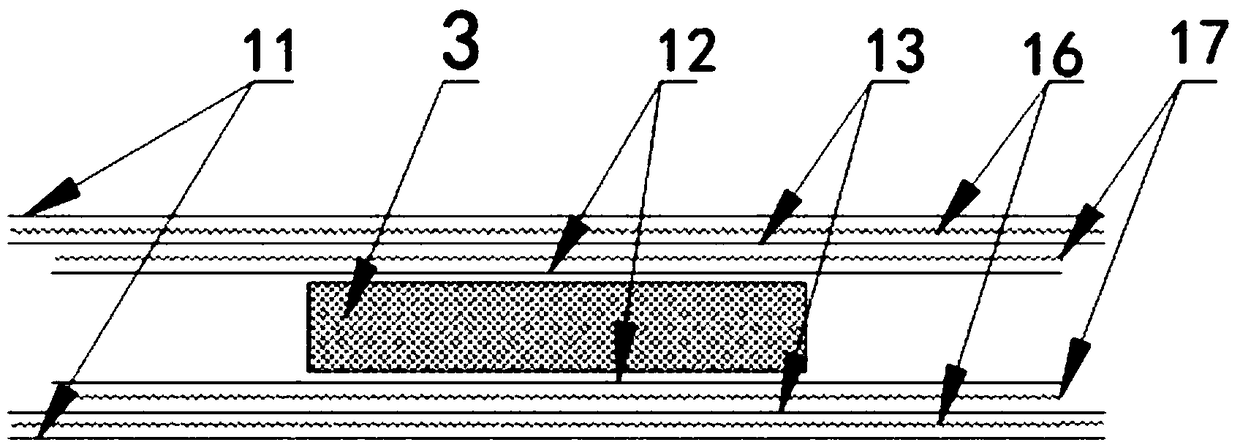

[0049] The full waistline 1 includes an inner waistline 12, an outer waistline 11 and an elastic material layer 13, the inner waistline 12 is made of cotton material, and the non-woven fabric layer is the outer waistline 11. The production technology of the novel diaper product of the present embodiment comprises the following steps:

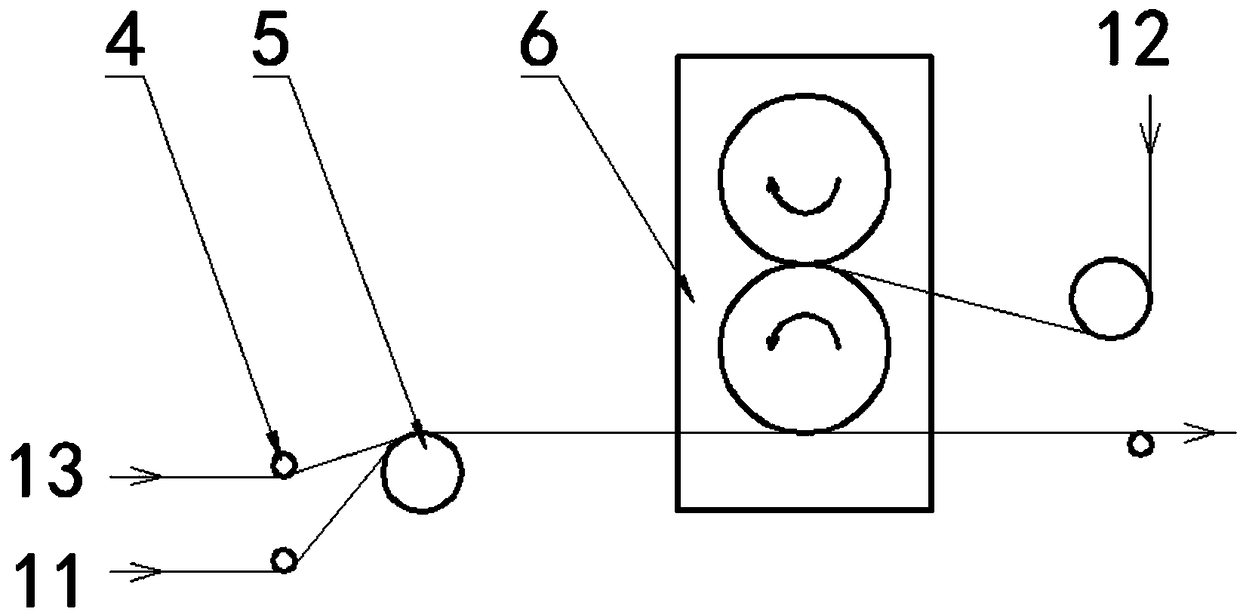

[0050] Step 1: the outer waistline 11 is first compounded with the elastic material layer 13, and the elastic material layer 13 and the outer waistline 11 are pasted together by the first composite glue 16 to form the first complex;

[0051] Step 2: the inner waistline 12 is cut off by the inner waistline chopping assembly 6 and pasted intermittently on the first complex by the second composite glue 17 to form the full waistline 1;

[0052] Step 3: The full waist 1 is compounded with the absorber 3 to form a product;

[0053] Step 4: The product is sent to the waist sealing mechanism through the conveying mechanism for sealing, and the two oute...

Embodiment 2

[0055]The full waistline 1 includes an inner waistline 12, an outer waistline 11, a covering non-woven fabric 14 and an elastic material layer 13, the material of the inner waistline 12 is cotton material, and the non-woven fabric layer is a covering layer 14 pasted on the inner side of the inner waistline 12. .

[0056] The production technology of the novel diaper product of the present embodiment comprises the following steps:

[0057] Step 1: the outer waistline 11 is first compounded with the elastic material layer 13, and the elastic material layer 13 and the outer waistline 11 are pasted together by the first composite glue 16 to form the first complex;

[0058] Step 2: The inner waistline 12 is cut off by the inner waistline chopped assembly 6 and pasted intermittently on the first composite body through the second composite glue 17;

[0059] Step 3: The covering layer 14 is cut off by covering the non-woven fabric chopped assembly 7 and pasted on the intermittent inn...

Embodiment 3

[0063] The non-woven fabric layer is the middle waistline 15 pasted between the elastic material layer 13 and the inner waistline 12 .

[0064] The material of the outer waistline 11 is non-woven fabric, the material of the inner waistline 12 is cotton material, the material of the middle waistline 15 is non-woven fabric, or the material of the outer waistline 11 is cotton material, and the material of the inner waistline 12 is cotton material Material, the material of the middle waistline 15 is non-woven fabric.

[0065] The production technology of the novel diaper product of the present embodiment comprises the following steps:

[0066] Step 1: the outer waistline 11 is first compounded with the elastic material layer 13, and the elastic material layer 13 and the outer waistline 11 are pasted together by the first composite glue 16 to form the first complex;

[0067] Step 2: the middle waistline 15 is compounded with the first composite body, and the middle waistline 15 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com