89SrC12 solution concentration device and concentration method thereof

A technology for concentrating device and solution, applied in the field of nuclear chemical industry, can solve the problems of high production cost, occupy more resources, and more radioactive waste liquid, etc., and achieve the effects of high production efficiency, simple and practical process, convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

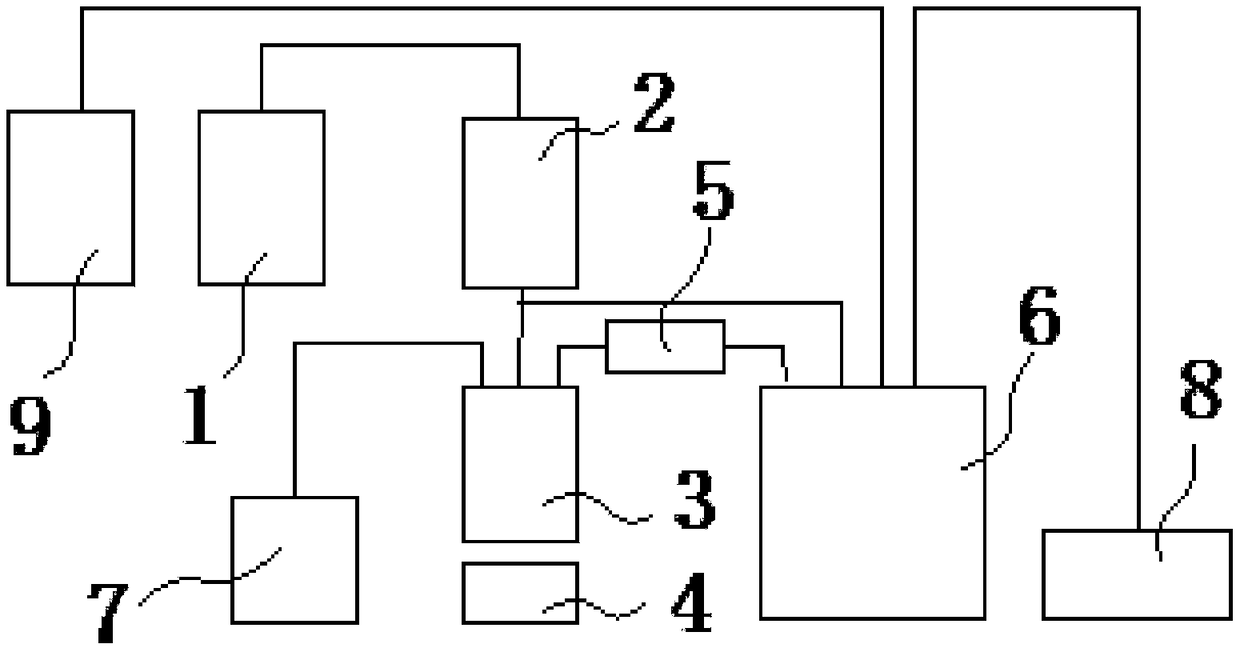

[0032] A sort of 89 SrCl 2 The solution concentration device includes a crushing device 1 , a filtering device 2 , a storage device 3 , a heating device 4 , a condensation device 5 , a waste liquid bottle 6 and a sampling device 7 .

[0033] Wherein, the storage device 3 is a three-necked bottle, and there are three outlets on the three-necked bottle, the first outlet communicates with the outlet of the filter device 2, the second outlet communicates with the waste liquid bottle 6 through the condensation device 5, and the third outlet communicates with the sampling device 7 connected, such as figure 1 shown.

[0034] In this embodiment, the waste liquid bottle 6 is also provided with a vacuum pump 8, and the interface of the whole device of the present invention adopts a ground design, which can ensure good air tightness and is suitable for quick assembly and installation.

[0035] Concentration process of the present invention is:

[0036] The first step is to move the c...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the structure of the present invention is optimized in this embodiment, and the specific settings are as follows:

[0045] The outlet of the filter device 2 is also provided with a connecting pipe communicating with the waste liquid bottle 6. Through the arrangement of this structure, the liquid of the cleaning filter device can be collected directly into the waste liquid bottle 6, reducing the amount of radioactive waste produced. The waste liquid bottle 6 is also communicated with a cleaning device 9 for cleaning the quartz tube target.

[0046] The filter device 2 is also provided with an air extraction interface, through which the air extraction interface can be used for suction filtration, and the filtration speed is faster. The material of the three-necked bottle is glass and quartz, and the three-necked bottle has volume scale marks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com