PH-responsive oil-water separation material and preparation method and application thereof

An oil-water separation and responsive technology, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of large energy consumption of high-voltage electrostatic fields, environmental pollution of separation membranes, complex preparation processes, etc., and achieve high-efficiency separation and raw materials. Inexpensive and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

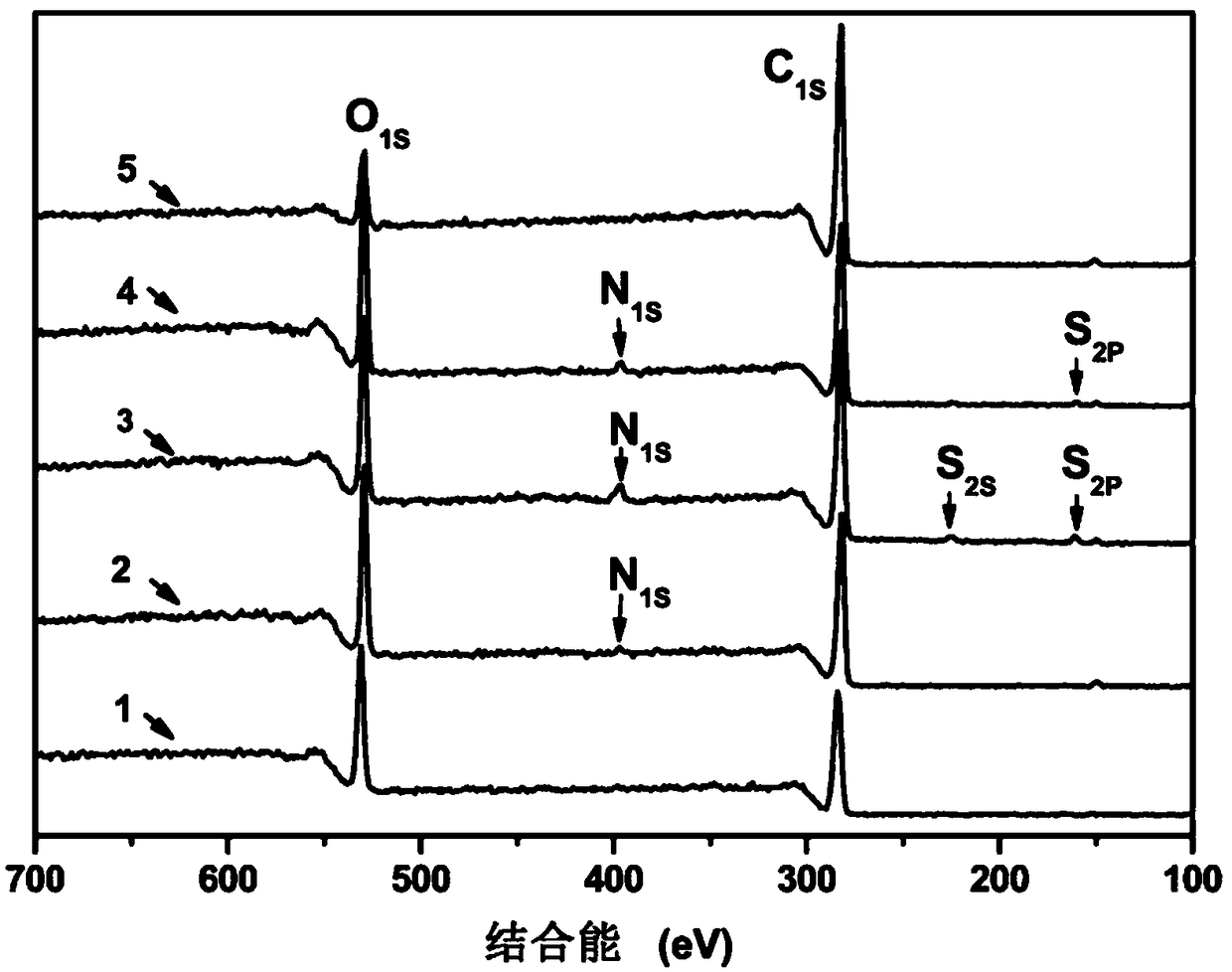

[0038] A preparation method of a pH-responsive oil-water separation material, comprising the steps of:

[0039] (1) The cotton cloth is ultrasonically cleaned with deionized water and ethanol in turn, and dried for later use;

[0040] (2) Prepare 100ml of Tris buffer solution with a pH value of 6 and a concentration of 20mM, and dissolve 0.02g of dopamine into the acid-base buffer (Tris buffer solution) to obtain a dopamine-Tris buffer solution;

[0041](3) Soak the cotton cloth in the dopamine-Tris buffer solution and shake it. After 24 hours, obtain a cotton cloth with uniform deposition of polydopamine, then wash it with deionized water 10 times, soak it in the aqueous solution overnight, and then dry it;

[0042] (4) Prepare a pH value of 8 and a concentration of 10 mM Tris buffer solution, dissolve cystamine dihydrochloride in the Tris buffer solution, and control the concentration to 0.05mol / L to obtain cystamine dihydrochloride solution ;

[0043] (5) Soak the cotton ...

Embodiment 2

[0053] A preparation method of a pH-responsive oil-water separation material, comprising the steps of:

[0054] (1) The stainless steel filter screen is ultrasonically cleaned with deionized water and ethanol in turn, and dried for later use;

[0055] (2) Prepare 100ml of sodium dihydrogen phosphate-citric acid buffer solution with a pH value of 8 and a concentration of 30mM, and dissolve 0.06g of 2-hydroxyphenylalanine into the acid-base buffer solution (sodium dihydrogen phosphate-citric acid buffer solution), obtain 2-hydroxyphenylalanine / sodium dihydrogen phosphate solution;

[0056] (3) Soak the stainless steel filter in 2-hydroxyphenylalanine-sodium dihydrogen phosphate solution and shake it. After 18 hours, a stainless steel filter with uniform deposition of 2-hydroxyphenylalanine is obtained, and then wash it with deionized water Multiple times, soak in aqueous solution overnight and then dry;

[0057] (4) Prepare a pH value of 8, a concentration of 15mM sodium dihyd...

Embodiment 3

[0064] A preparation method of a pH-responsive oil-water separation material, comprising the steps of:

[0065] (1) Clean the copper grid with deionized water and ethanol ultrasonically in turn, and dry it for later use;

[0066] (2) Prepare 100ml of Tris buffer solution with a pH value of 8.5 and a concentration of 10mM, and dissolve 0.05g of dopamine in the acid-base buffer solution to obtain a dopamine-Tris buffer solution;

[0067] (3) Soak the copper grid in the dopamine-Tris buffer solution and shake it. After 12 hours, the copper grid with uniform deposition of polydopamine was obtained, and then washed with deionized water several times, soaked in the aqueous solution overnight and then dried;

[0068] (4) Prepare a Tris buffer solution with a pH value of 8.5 and a concentration of 5mM, and dissolve cystine hydrochloride in the Tris buffer solution with a concentration of 0.05mol / L;

[0069] (5) Soak the copper mesh dried in step (3) in cystine hydrochloride solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap