Organosilicon composition and preparation method thereof

A technology of organosilicon and composition, which is applied in the field of fine chemical preparations and can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

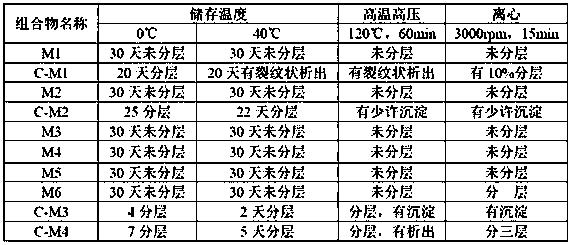

Image

Examples

Embodiment 1

[0060] Preparation of active substance A

[0061] A-1: prepared according to the method of example 1 of US4639489A;

[0062] A-2: prepared according to the method of Example 1 of US2009234029A1;

[0063] A-3: Prepared according to the method of Example 1 of US6521586B1.

Embodiment 2

[0065] Selection of B of hydroxyl polysiloxane

[0066] B-1: Polysiloxane with terminal hydroxyl groups, the dynamic viscosity at 25°C is 100,000mPa·s;

[0067] B-2: Polysiloxane with terminal hydroxyl groups, the dynamic viscosity at 25°C is 10mPa·s;

[0068] B-3: Polysiloxane with terminal hydroxyl groups, the dynamic viscosity at 25°C is 20,000mPa·s;

[0069] B-4: Hydroxyl-terminated polysiloxane with a dynamic viscosity of 100mPa·s at 25°C;

[0070] B-5: Hydroxyl-terminated polysiloxane having a dynamic viscosity of 50,000 mPa·s at 25°C.

Embodiment 3

[0072] Selection of Polyether Modified Polysiloxane C with Spatial Structure

[0073] C-1: The value of each subscript in the molecular structure: polyether G middle r = 12; s = 38; R 2 = hydrogen atom; f =2; g =80; h =20; i =60, the dynamic viscosity of the obtained spatially structured polyether-modified polysiloxane is 15,000mPa·s at 25°C;

[0074] C-2: The value of each subscript in the molecular structure: polyether G middle r = 1; s = 75; R 2 = methyl; f =1; g = 2; h =4; i =90, the dynamic viscosity of the obtained spatially structured polyether-modified polysiloxane is 110mPa·s at 25°C;

[0075] C-3: The value of each subscript in the molecular structure: polyether G middle r = 70; s = 30; R 2 = isobutyl; f =3; g =100; h =90; i =20, the dynamic viscosity of the obtained spatially structured polyether-modified polysiloxane is 47,000mPa·s at 25°C;

[0076] C-4: The value of each subscript in the molecular structure: polyether G middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com