Device and method for controlling precision of automatic preparation of emulsion

A technology of precision control and automatic preparation, applied in chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve the problem that the precision of emulsion preparation cannot be effectively guaranteed, the mass ratio of water and emulsified oil cannot be accurately measured, and it is difficult to realize real-time Controlling issues such as emulsion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

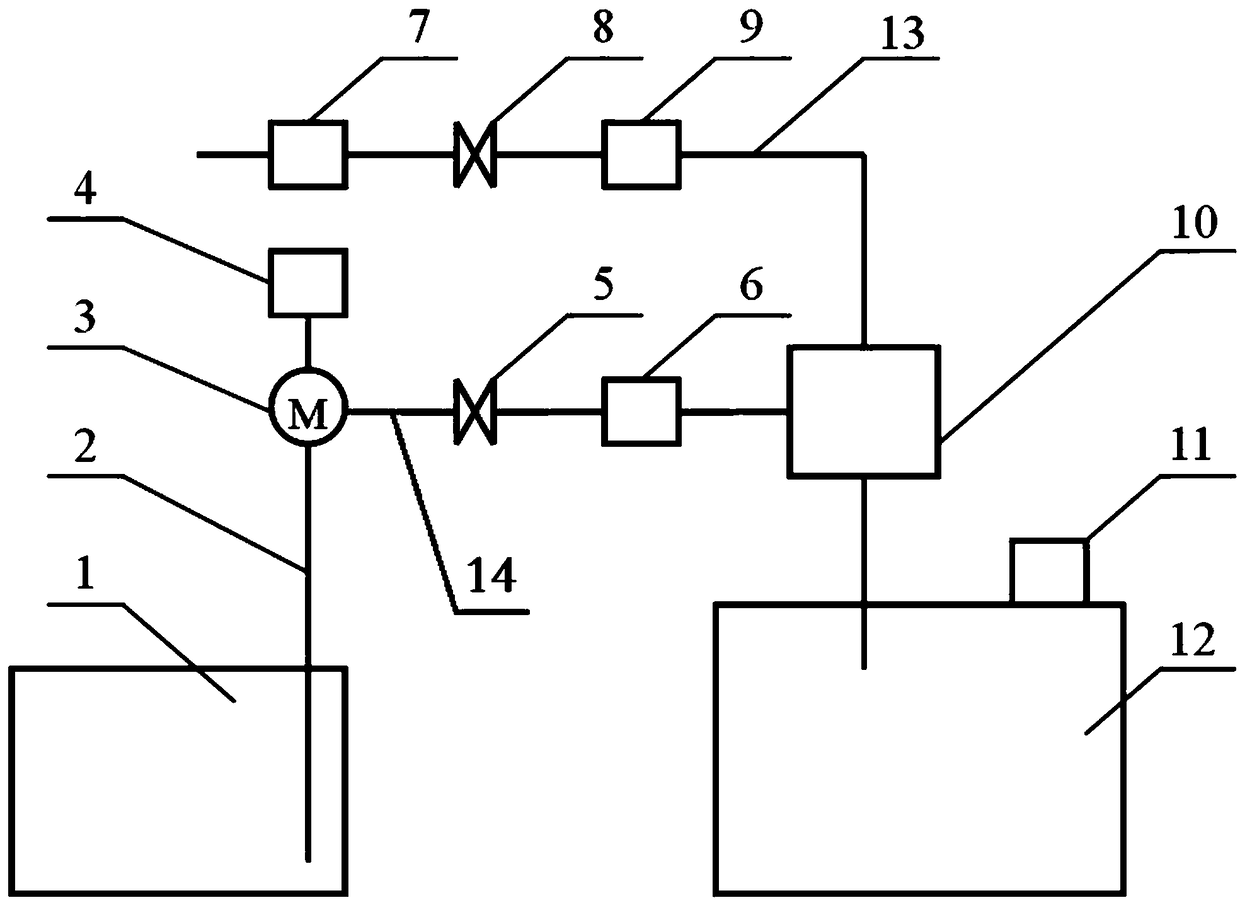

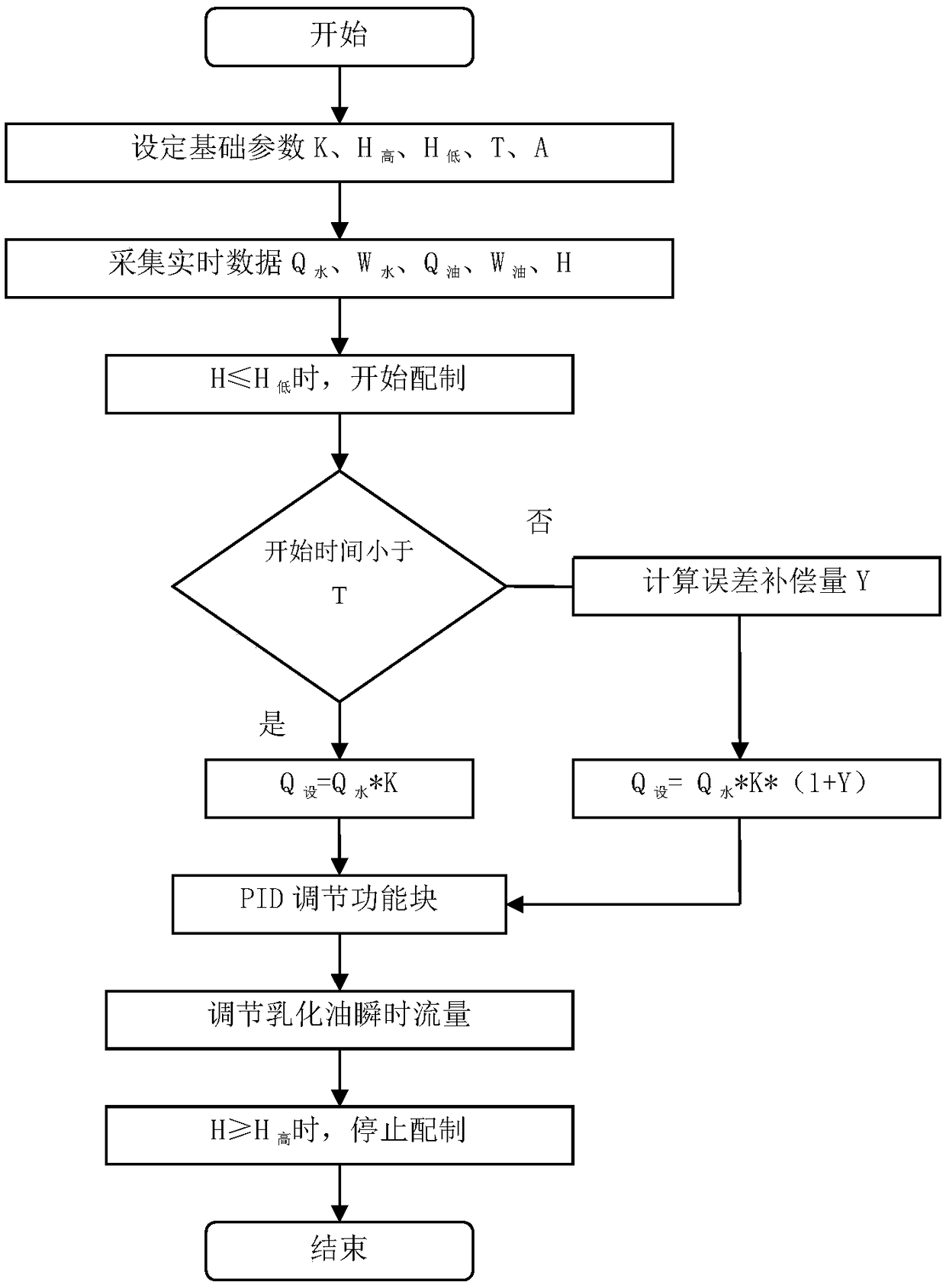

[0046] Generally, the concentration of the emulsion is required to be in the range of 3% to 5%. In this example, the mixing ratio K of emulsified oil and water is set to 4%. According to the actual situation of the field equipment, the upper limit H of the liquid level of the emulsion tank 12 is set. is 1.2 meters, the lower limit H of the liquid level is 0.3 meters, the delay error compensation time T is 15 seconds, and the error compensation coefficient A is 2.

[0047] According to the diameter of the water pipe on site, the pressure of the water source is adjusted to 0.3MPa through the pressure regulating valve 7, and the water flow Q water is basically kept at about 500Kg / h.

[0048] When working, the liquid level value H in the emulsion tank 12 is detected in real time by the liquid level detector 11. When H≤0.3m, the frequency conversion motor 4, the oil circuit solenoid valve 5 and the water filling solenoid valve 8 are turned on to start preparing the emulsion.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com