Dust particle control device and system

A technology for dust particles and control devices, applied in chemical instruments and methods, cleaning methods and appliances, magnetic separation, etc. The effect of uniform force and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

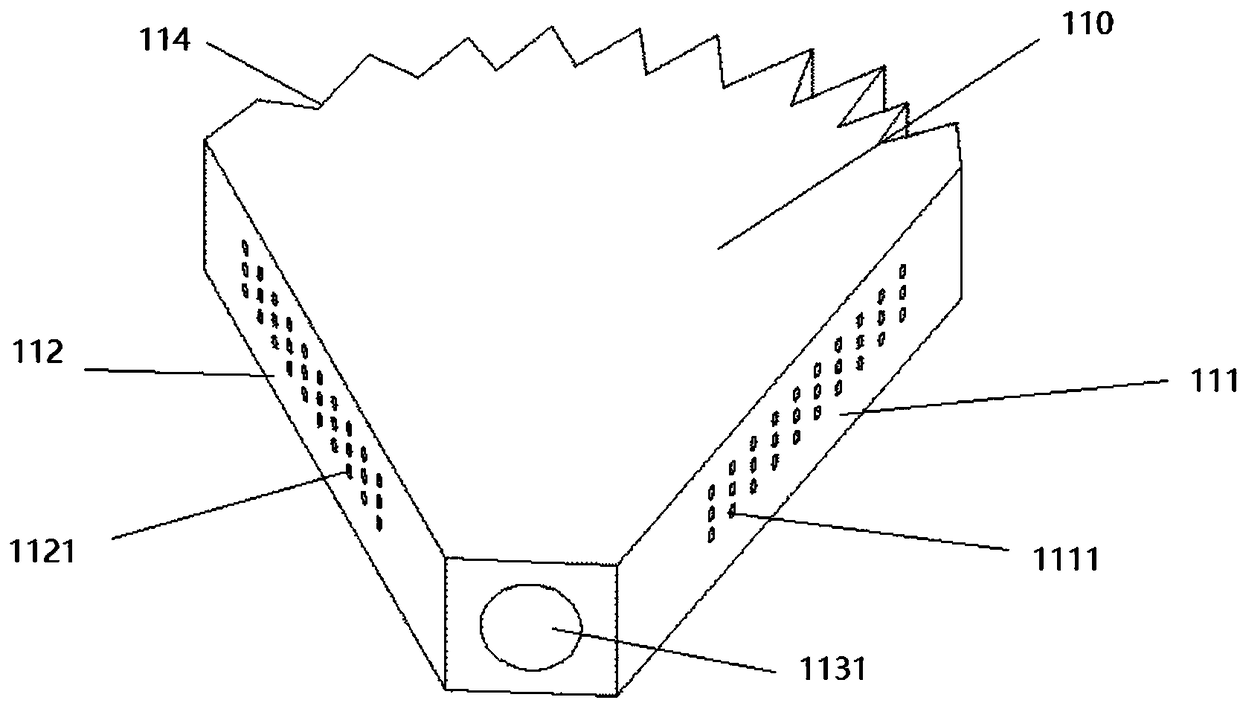

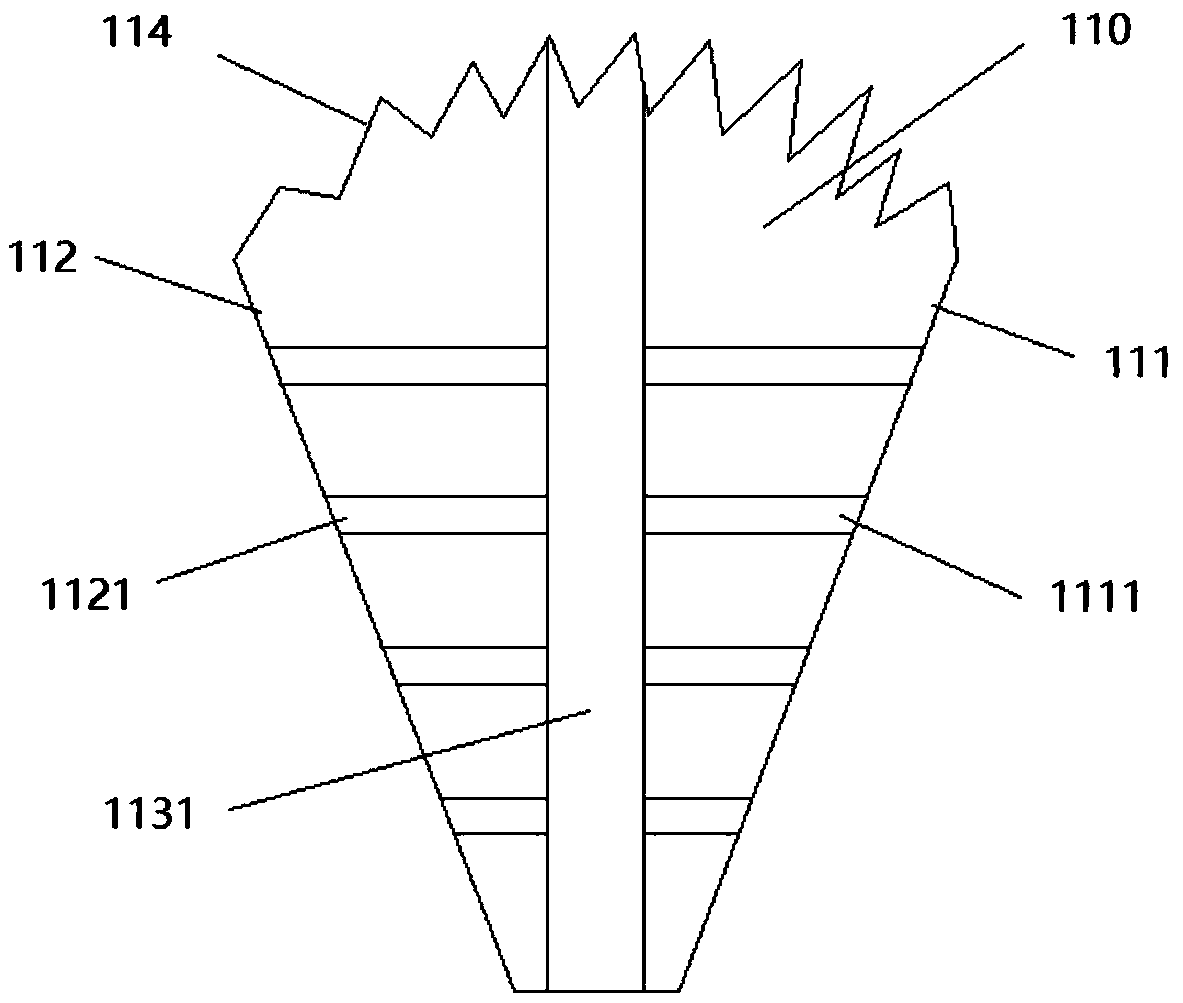

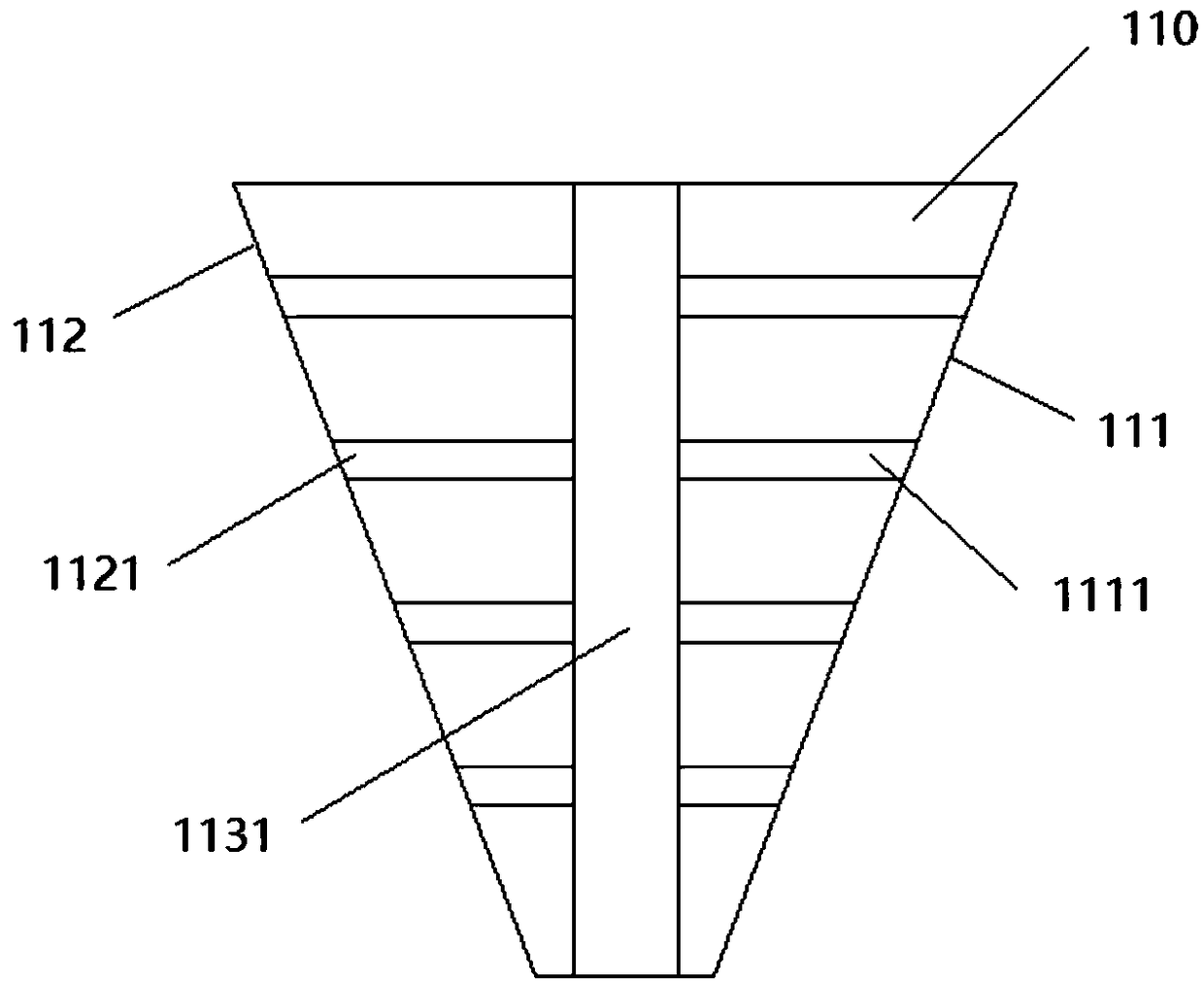

[0041] figure 1 Schematic diagram of the structure of the first structure of the dust particle control device provided by the embodiment of the present invention from a first perspective; figure 2 Schematic diagram of the second view of the first structure of the dust particle control device provided by the embodiment of the present invention; image 3 Schematic diagram of the second structure of the dust particle control device provided by the embodiment of the present invention; Figure 4 It is a schematic structural diagram of the third structure of the dust particle control device provided by the embodiment of the present invention.

[0042] Such as Figure 1 to Figure 4 As shown, a dust particle control device 100 is provided in this embodiment, and the dust particle control device 100 includes a dust removal body 110;

[0043] The dust removal body 110 includes an iron removal surface 111 and a static electricity removal surface 112 arranged at an angle; the intersec...

Embodiment 2

[0068] Figure 5 Schematic diagram of the structure of the dust particle control system provided by the embodiment of the present invention.

[0069] Such as Figure 5 As shown, the dust particle control system provided in this embodiment includes the dust particle control device 100 provided in the first embodiment, and the technical solution described in the first embodiment also belongs to this embodiment.

[0070] Specifically, as Figure 5 As shown, a dust particle control system is provided in this embodiment, the dust particle control system includes a winding machine 200, and the dust particle control device 100;

[0071] The winding machine 200 is provided with a positive pole piece fixing position 210, a negative pole piece fixing position 220, and two separator fixing positions 230; the positive pole piece fixing position 210, the negative pole piece fixing position 220, And the two isolation membrane fixing positions 230 are arranged symmetrically with respect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com