Collecting and conveying pipeline segmented pipe cleaning system and method

A pigging and pipeline technology, which is applied in the field of segmented pigging systems for gathering and transportation pipelines, can solve the problems of low cost performance, stuck balls, and low frequency of use, and achieves the effects of long digestion time, simple structure and clear functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

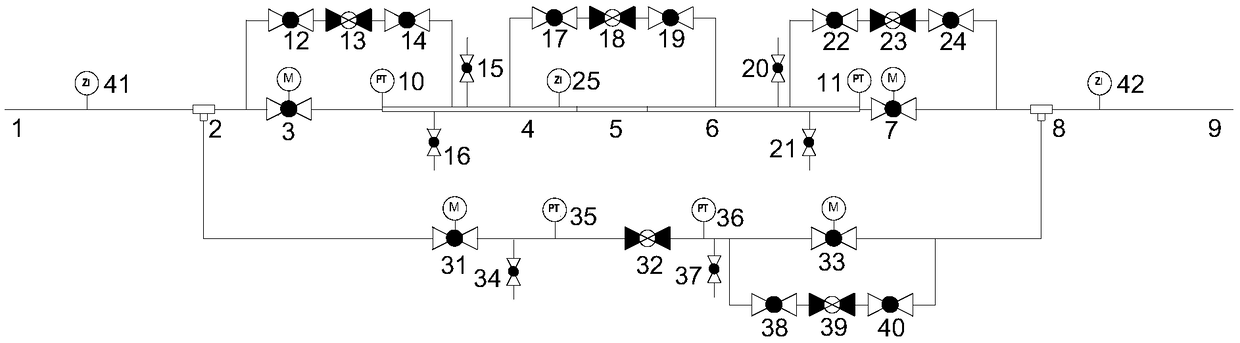

[0025] A segmented pigging system for gathering and transportation pipelines, such as figure 1 and figure 2 as shown,

[0026] The total system includes: the first station A, the intermediate pigging system 1#, the intermediate pigging system 2#, ..., the intermediate pigging system n# and the final station B; After the selection, it is used to reduce the one-time long-distance pigging slug load, the downstream pigging first, and then the upstream pigging.

[0027] Each intermediate pigging system is a separate subsystem, including: upstream incoming pipeline 1, upstream reducing bar tee 2, upstream main line ball valve 3, first-stage thick-walled pipe joint 4, second-stage thick-walled pipe joint 5, Third-stage ball joint 6, downstream main line ball valve 7, downstream reducing bar tee 8, downstream outbound pipeline 9, main line pressure transmitter 10 / 11, bypass ball valve 12 / 14 / 17 / 19 / 22 / 24. Bypass control valve 13 / 18 / 23, gas release replacement valve 15 / 20, liquid re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com