Vapor seal measuring tool machining method

A technology of measuring tools and processing methods, applied in measuring devices, instruments, etc., can solve the problems of difficulty in ensuring the accuracy of steam seal measuring tools, and achieve the effect of ensuring the processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

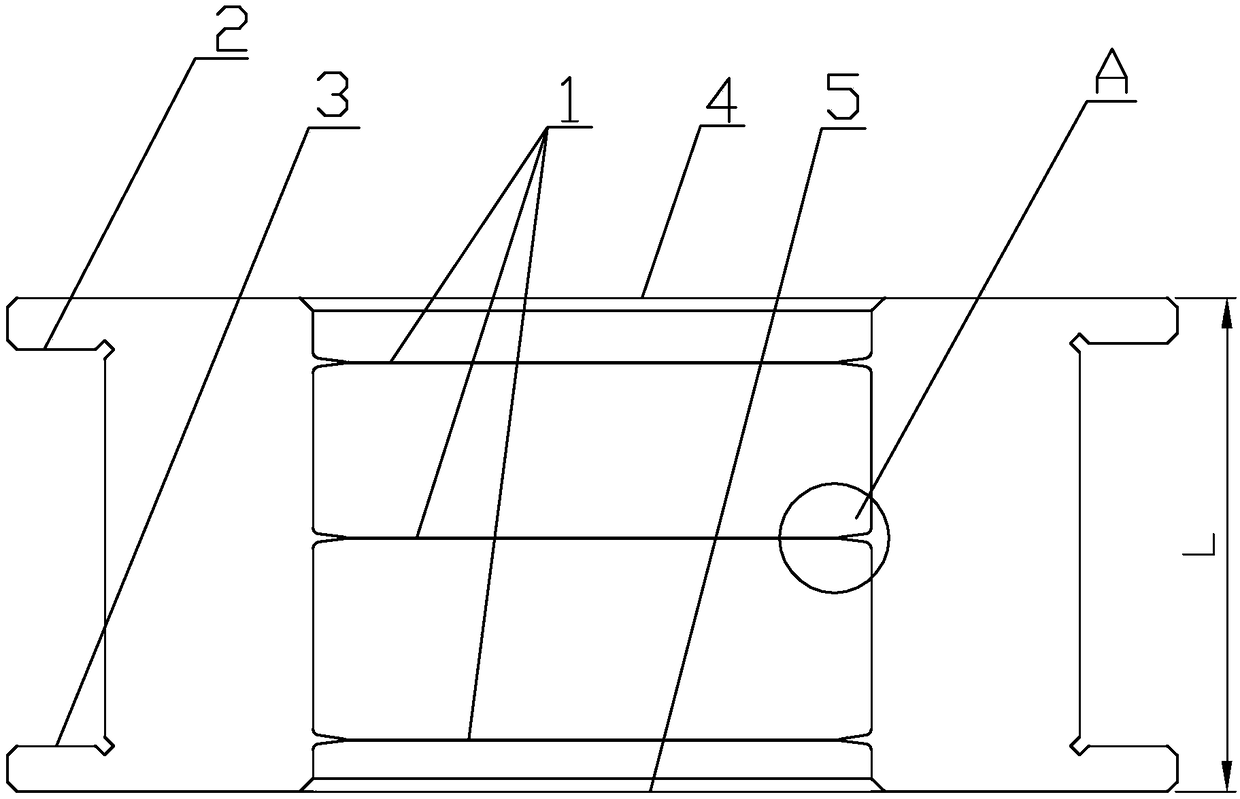

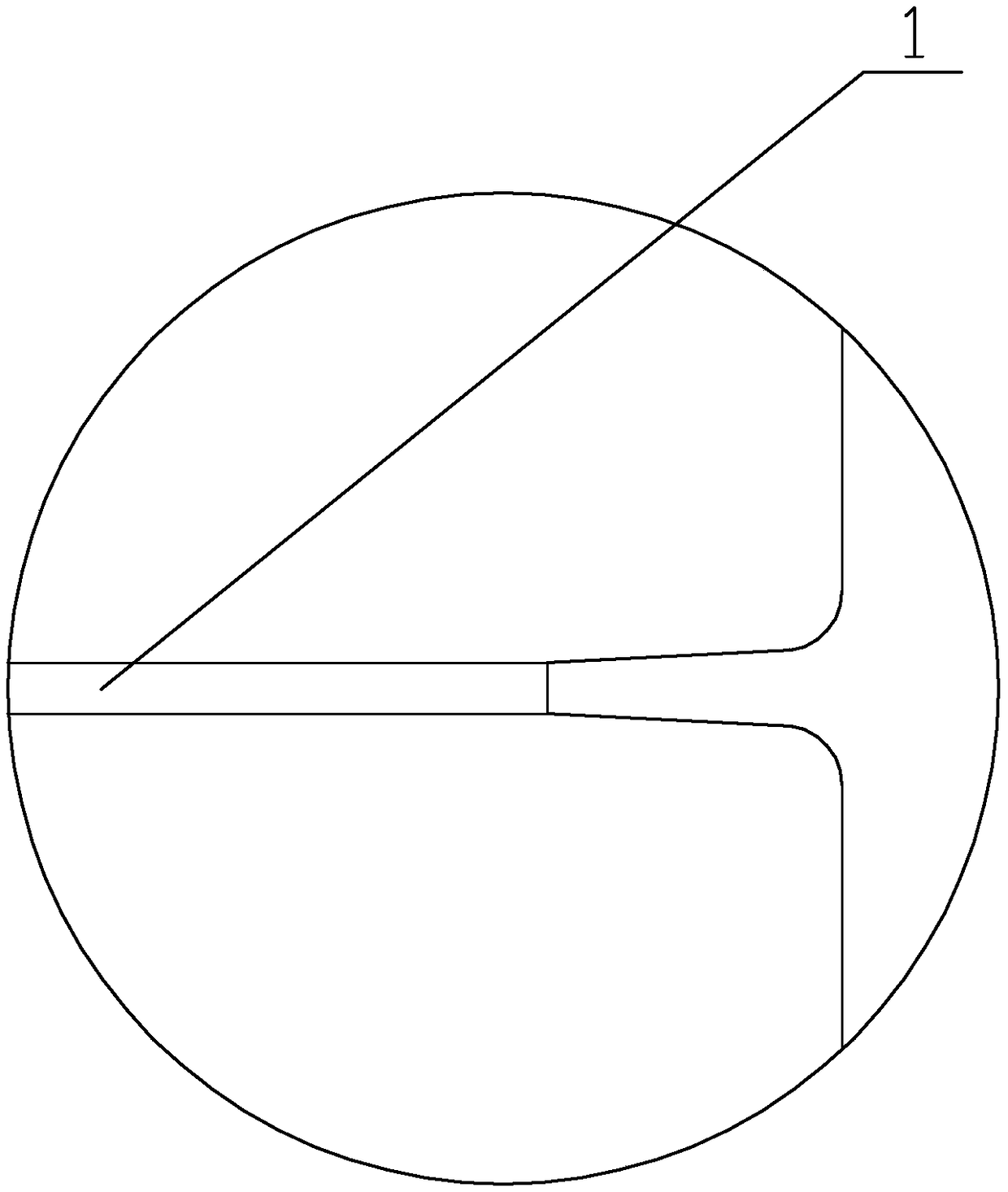

[0019] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a kind of steam seal measuring tool processing method, it comprises the following steps:

[0020] Step 1: Roughly turn each part on an ordinary lathe, each outer circle and end face should be heavy-duty on one side by 3mm, and the inner hole and the tooth surface of the steam seal should be heavy-weight on one side by 3mm;

[0021] Step 2: heat treatment, the workpiece is heat treated to HRC31-35;

[0022] Step 3: Finish turning each part of the CNC lathe, end face A2, end face B3, end face C4 and end face D5, each end face has a volume of 0.3 mm, and the rest of the parts are fine-turned to the specified size;

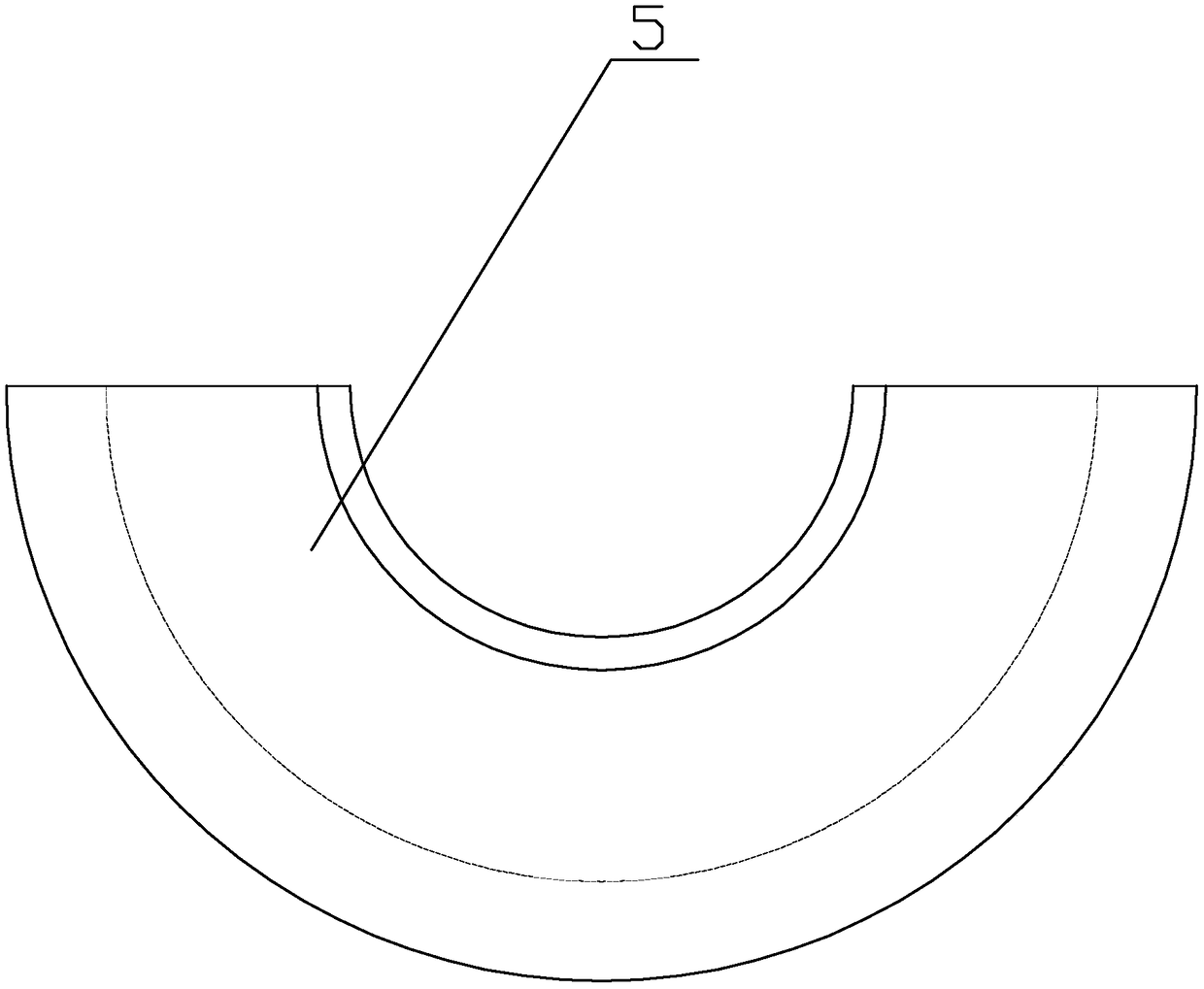

[0023] Step 4: Grinding on a surface grinder, grinding the end face C4 and the end face D5;

[0024] Step 5: The fitter draws the center line;

[0025] Step 6: Wire cutting machine, cut the gas seal measuring tool along the middle split surface line;

[0026] Step 7:...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the cutting parameters in step 1 are: rotational speed 180r / min, feed rate 0.3mm / r, cutting depth 2mm. Beneficial effects of this embodiment: good cutting effect. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the cutting parameters in Step 3 are: rotational speed 200r / mm, feed rate 0.1mm / r, cutting depth 1.5mm. Beneficial effects of this embodiment: the machining accuracy of the gear surface of the steam seal is ensured. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com